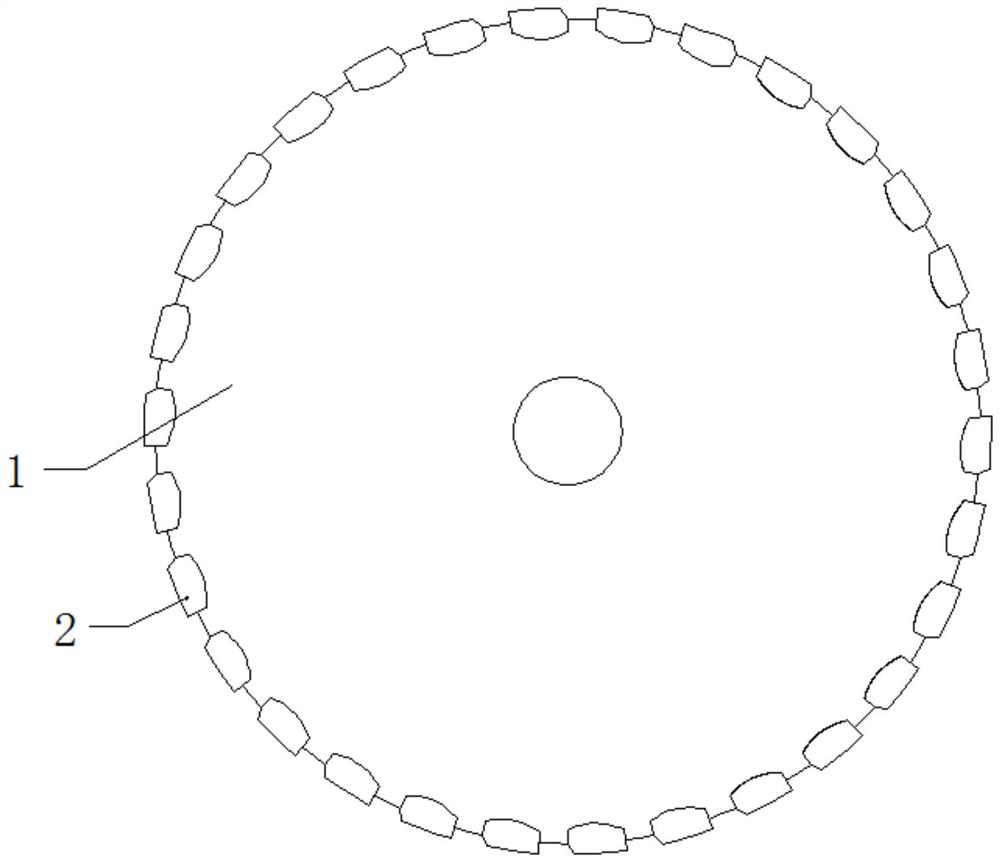

Rock plate saw blade with replaceable tool bits and manufacturing process of rock plate saw blade

A technology of saw blades and cutter heads, which is applied in the field of slate saw blades and its manufacturing process, can solve problems such as difficulties, large cutting, and large wear of slate saw blades, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

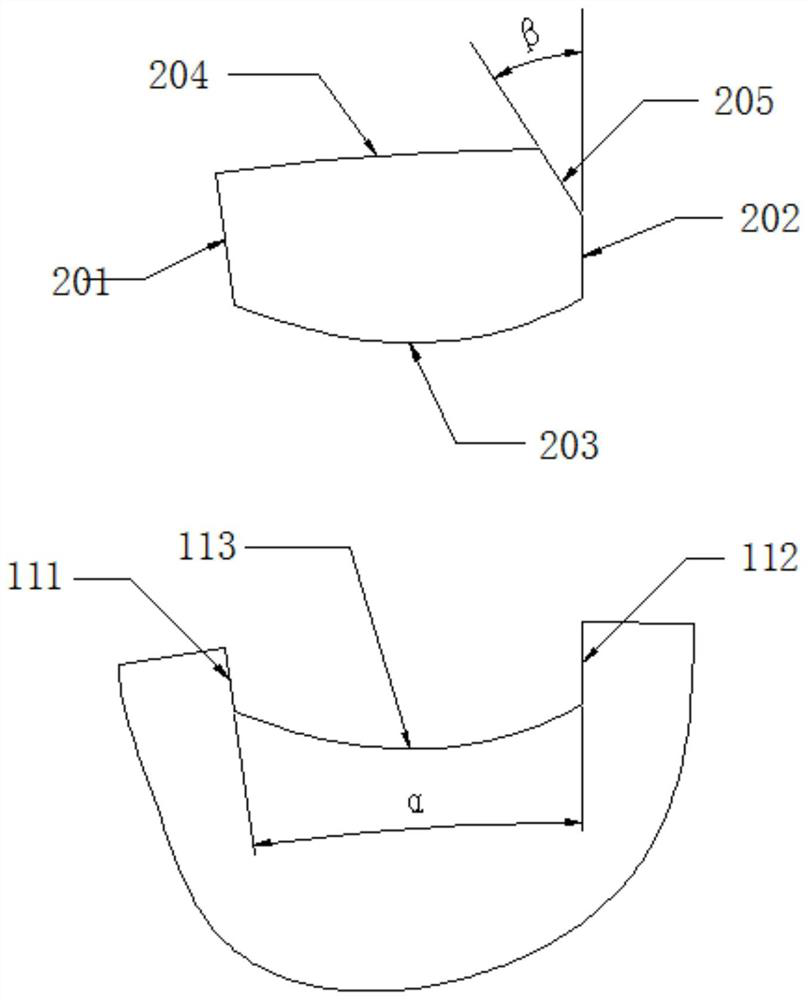

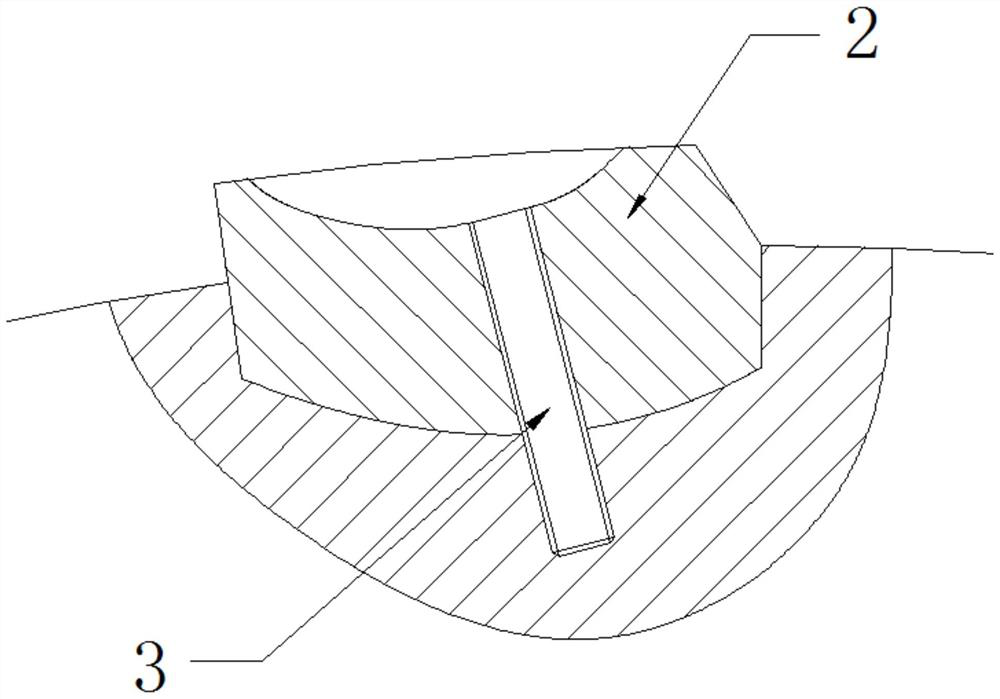

[0039] As an embodiment, the surface of the replaceable tip 2 E G surfaces 202 and 204 is also provided with a H between the face 205, the H-plane angle β is formed between the surface 205 and E 202;

[0040] In the present embodiment, 30 ° ≤β less 40 °.

[0041] As an embodiment, the replaceable tip 2 via powder metallurgy is obtained by hot pressing the diamond saw blade.

[0042] As an embodiment, the blade base body 1 made of a 75Cr1 or 8CrV, 75Cr1 8CrV and high-quality steel, preferably obtained after heat treatment and mechanical properties inherent quality, to ensure multi-blade basic body re-use.

[0043] One kind of bit slab replaceable blade manufacturing process, comprising the steps of:

[0044] Step 1, in an outline of the sheet cutting blade and a central hole of the base body 1;

[0045] Step 2, an outer blade matrix processing fixing groove;

[0046] Step 3, the base of the saw blade 1 quenching, tempering;

[0047] Step 4, to adjust the flatness of the blade base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com