Die-casting machine with automatic feeding function and using method thereof

An automatic feeding and die-casting machine technology, applied in the field of die-casting machines, can solve the problems of contamination of the processing raw liquid, poor use effect, poor conveying accuracy, etc., and achieves the effect of efficient and continuous acquisition, convenient dynamic control, and increasing the range of reclaiming materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

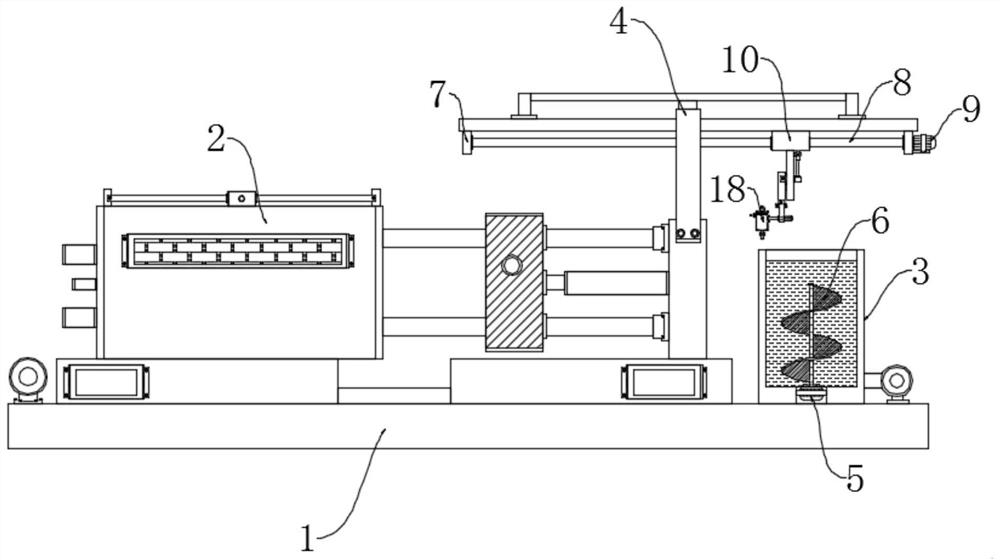

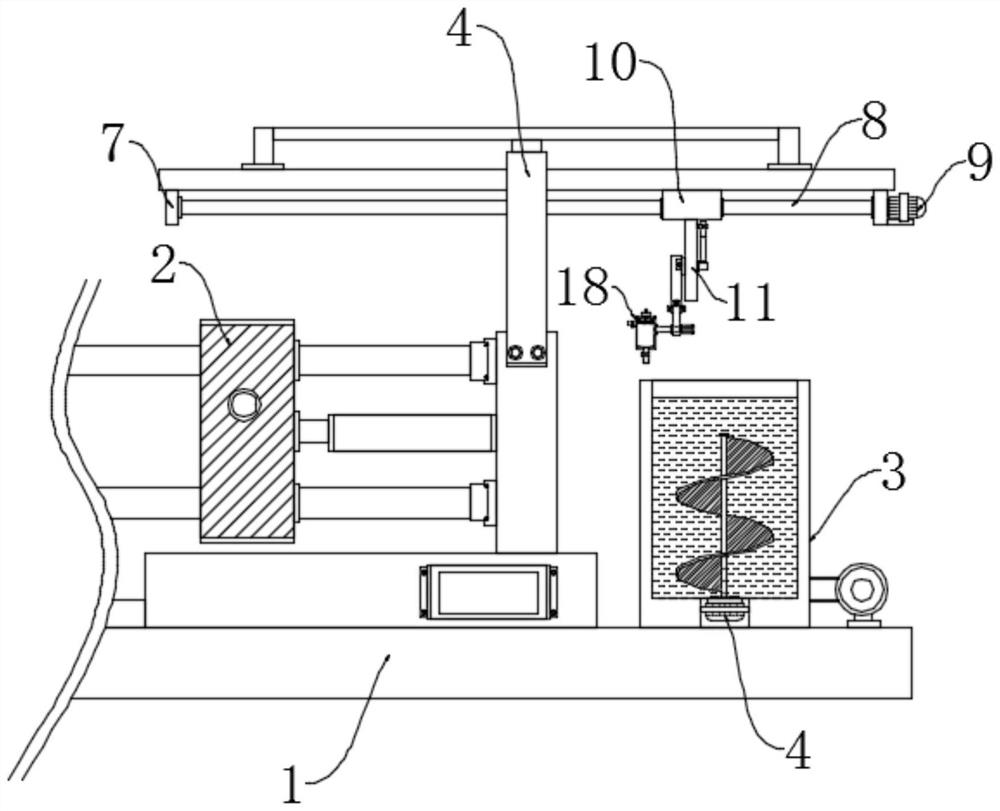

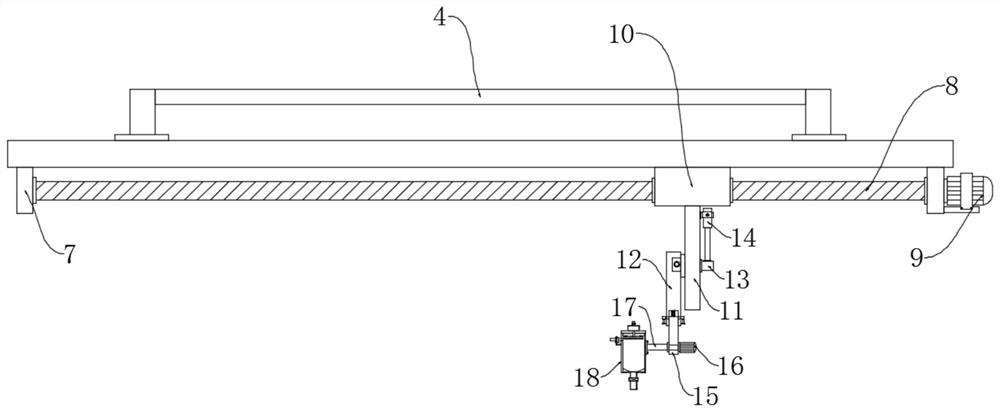

[0035] see Figure 1-7 , the present invention provides a technical solution: a die-casting machine with automatic feeding function, including a base 1, a die-casting machine body 2, a furnace 3, a positioning frame 4, a guide assembly, a lifting assembly, a retrieving assembly and an auxiliary cleaning assembly , the die-casting machine body 2 is correspondingly assembled on one side of the upper surface of the base 1, the melting furnace 3 is correspondingly installed on the other side of the upper surface of the base 1, the positioning frame 4 is installed above the die-casting machine body 2, and the guide The assembly is installed on the positioning frame 4, the lifting assembly is installed on the guide assembly, the retrieving assembly is matched and installed on the elevating assembly, and the two ends of the retrieving assembly are connected with the die-casting machine body 2 and the furnace 3 respectively. The auxiliary cleaning components are correspondingly instal...

Embodiment 2

[0045] A die-casting machine with automatic feeding function and its use method,

[0046] Include the following steps:

[0047] Step 1: first transport the processing raw liquid to the melting furnace 3, and drive the stirring blade 6 to rotate in the melting furnace 3 under the transmission of the driving motor 5, so as to ensure the activity of the processing raw liquid and ensure the good state of the processing raw liquid;

[0048] Step 2: By installing a material extraction component and an electronically controlled negative pressure pump 22, the gas inside the material extraction bin 18 is extracted by using the gas pipe 21, and the processing raw liquid inside the furnace 3 can be extracted into the material extraction bin 18 through the material extraction pipe 19 , to realize the efficient and continuous acquisition of the processing raw liquid, and at the same time, under the transmission of the turning motor 16, the retrieving bin 18 is driven to be offset and turne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com