Automatic fractional kernel removing device

A technology for nuclear device and hole filling, which is applied in the field of automatic and fractional denucleation devices, and can solve the problems of loss of nutrients, long processing cycle, loss of taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

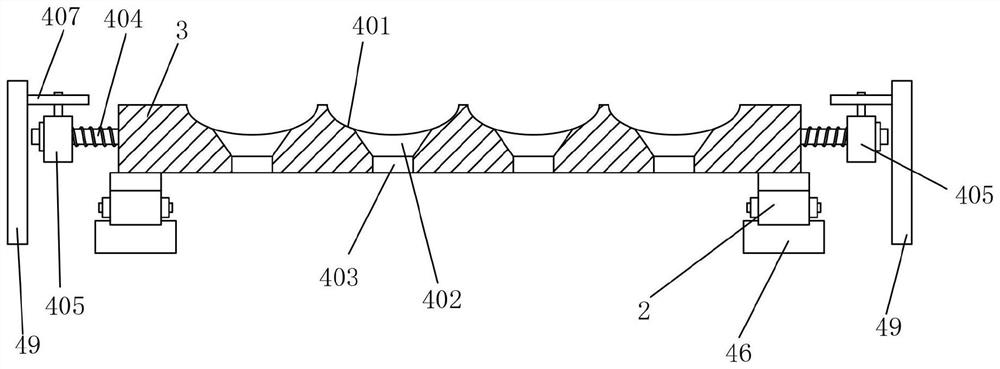

[0040] Embodiment: a kind of automatic grading denucleating device, such as Figure 1-Figure 17 As shown, it includes a device frame 1, a conveying system and a fractionated denucleating system, the conveying system is located at the lower side of the device rack 1 inside, and the fractionated denucleated system is located at the upper side of the device rack 1 inside and is located at the inside of the device rack 1. Above the middle part of the conveying system, the conveying system includes a conveying chain belt 2, a conveying module 3 and a power transmission device, the conveying module 3 is in the shape of a long cube, and the transverse middle part of the conveying module 3 is uniformly arranged There are several filling holes 4, the filling holes 4 run through the upper and lower sides of the delivery module 3, the upper end of the filling holes 4 is an arc groove 401, and the middle part of the filling holes 4 is a horn shaped groove 402, the lower end of the filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com