Noise reduction and impurity removal pressure reduction regulating valve

A decompression regulating valve and noise reduction technology, applied in the direction of lift valve, valve detail, valve device, etc., can solve the problems of high noise, accumulation of impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

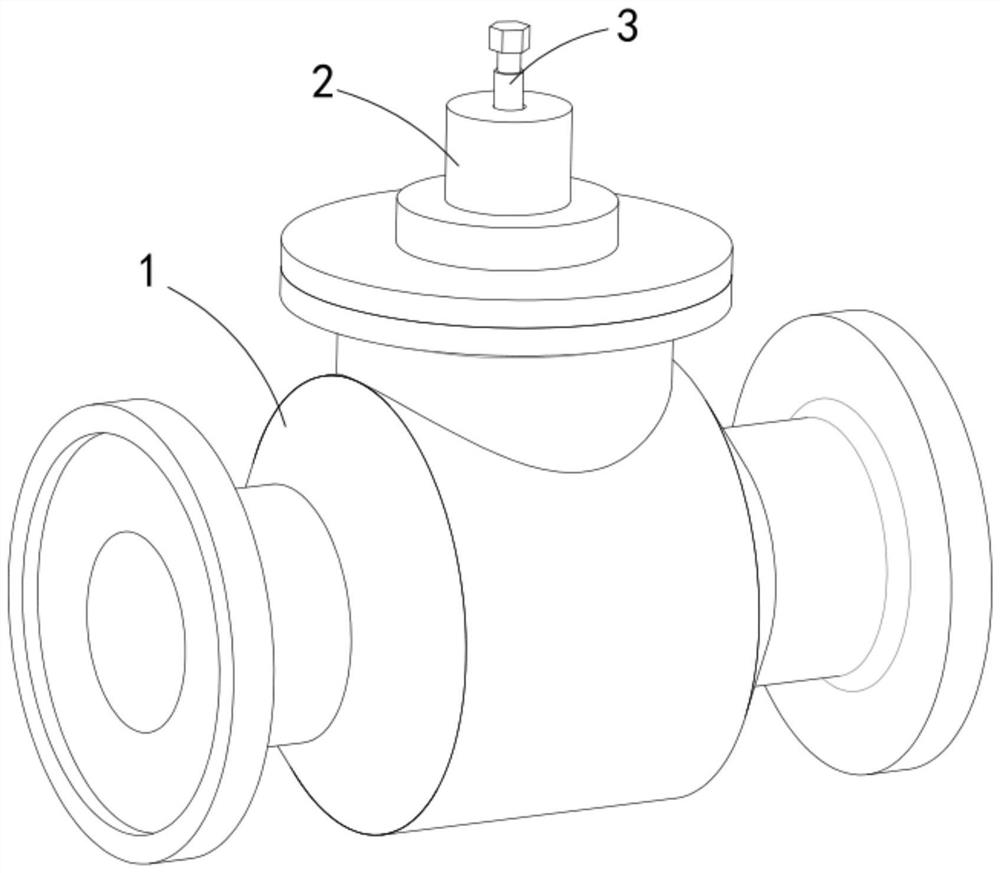

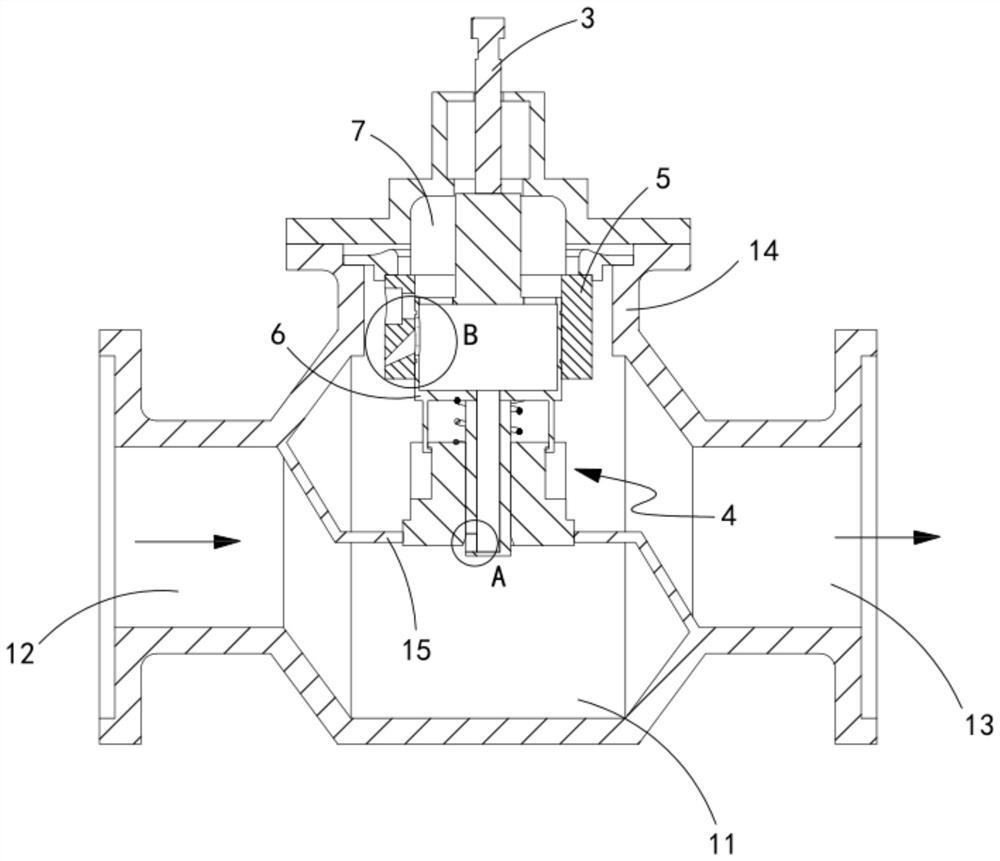

[0045] like figure 1 and 2 As shown in the figure, a noise reduction and impurity decompression regulating valve includes a valve body 1, a valve cover 2 and a valve stem 3. The valve body 1 is provided with a valve cavity 11, a water inlet channel 12, a water outlet channel 13 and a valve. The valve core installation port 14, the valve seat 15 is installed in the valve cavity 11, the valve cover 2 is sealed and installed on the valve core installation port 14, the valve stem 3 is slidably arranged in the valve cover 2, and also include:

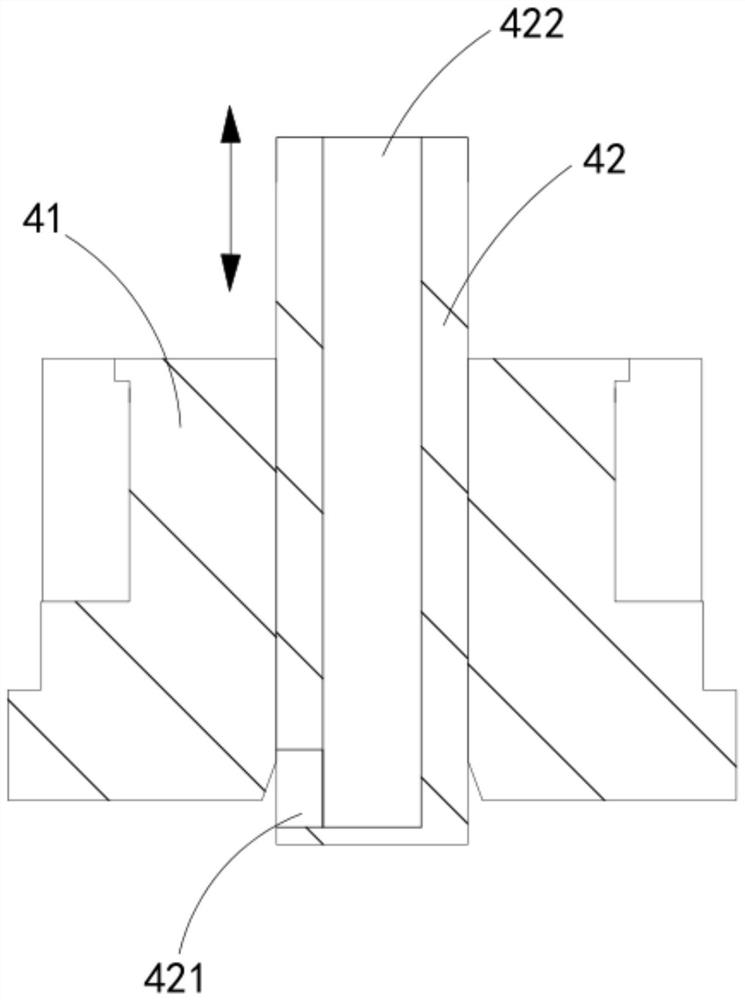

[0046]Combined spool mechanism 4, the combined spool mechanism 4 moves up and down along the axial direction of the core installation port 14 to cooperate with the valve seat 15 to open or close the gate, which includes a hollow outer spool 41 and sleeved on the valve core The inner spool 42 inside the outer spool 41 and vertically slides along the outer spool 41, the outer spool 41 and the inner spool 42 are spliced to form a complete s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com