Anode active material, method for manufacturing same, and anode and secondary battery each comprising same

A negative active material and negative electrode technology, applied in the direction of secondary batteries, active material electrodes, negative electrodes, etc., can solve problems such as no alternatives proposed, achieve the effect of reducing specific surface area, preventing cyclic expansion, and preventing expansion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

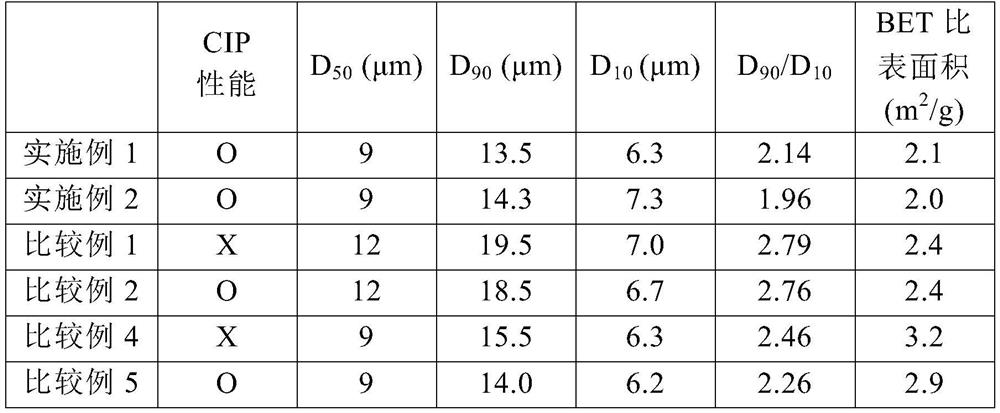

Examples

preparation example Construction

[0064] The method for preparing the negative electrode active material of the present invention includes the step of pressing the natural graphite by a cold isostatic pressing method. Through the cold isostatic pressing method, the fine pores existing in the negative electrode active material containing natural graphite can be effectively removed or reduced, and the specific surface area of natural graphite can be reduced to an appropriate level, so that the negative electrode activity thus prepared can be effectively prevented The problem of cyclic swelling of the material (this problem is caused by side reactions of the electrolyte).

[0065] The "cold isostatic pressing" method or CIP refers to a molding method in which powder is filled into a mold and compressed in infinite multiaxial directions by hydrostatic pressure. That is, according to the CIP process, the powder can be isostatically compressed, so that pores present in the molded negative electrode active material...

Embodiment 1

[0114] Embodiment 1: Preparation of negative electrode active material

[0115]

[0116] Natural graphite raw materials are collected from graphite ore by flotation, treated with acid or alkali to remove impurities, washed and dried to prepare flaky natural graphite. The flaky natural graphite obtained above was spheroidized using a vortex mill, treated with sulfuric acid to remove impurities therefrom, and then dried at 500° C. to prepare spherical natural graphite.

[0117] Spherical natural graphite was filled into a mold and pressurized by a cold isostatic pressing (CIP) method. During the pressurization, the pressurization pressure was 90 MPa, and the pressurization was performed for 100 seconds.

[0118] The pressed spherical natural graphite was mixed with pitch having a softening point of 130° C., and the mixture was heat-treated in a dry manner at 1250° C. for 24 hours in an inert atmosphere to form a carbon coating on the spherical natural graphite.

[0119] The ...

Embodiment 2

[0121] Embodiment 2: Preparation of negative electrode active material

[0122] Except D of the spherical natural graphite having the carbon coating formed thereon at the time of sieving after the carbon coating is formed in Example 1 10 、D 50 and D 90 Except adjusting to 7.3 μm, 9.0 μm, and 14.3 μm, respectively, the negative active material of Example 2 was prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com