High-voltage electric appliance storage device with high safety

A high-voltage electrical and safety technology, applied in the substation/distribution enclosure, substation/switchgear cooling/ventilation, substation/switch layout details, etc. Electrical safety and other issues, to avoid failures and ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present invention provides a technical solution: a high-voltage electric appliance placement device with high safety, including:

[0032] base 10;

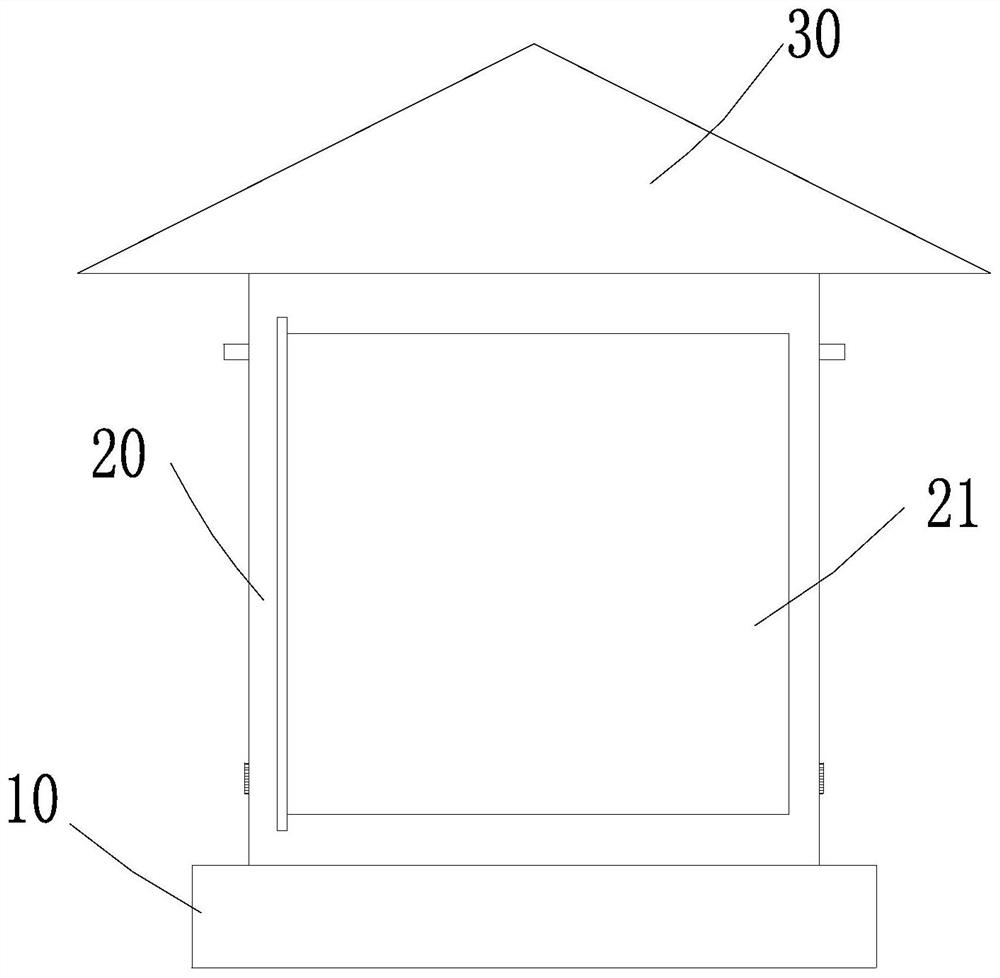

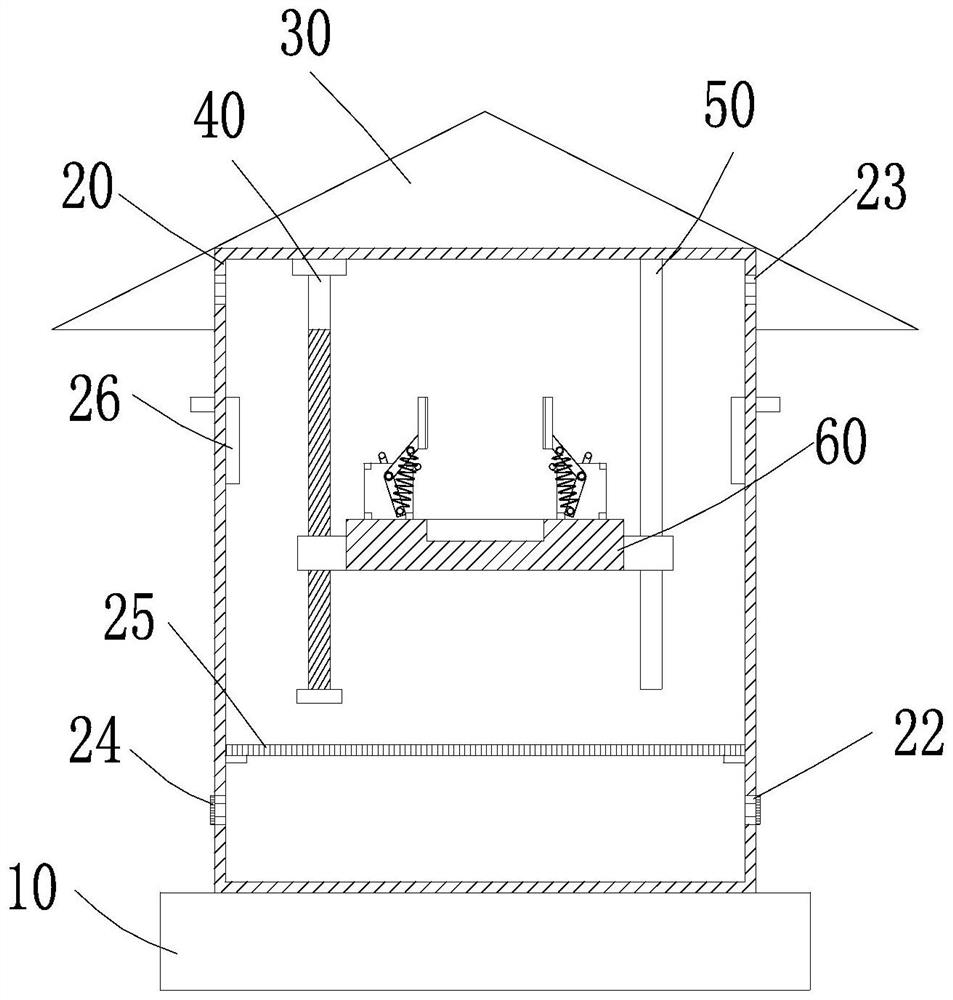

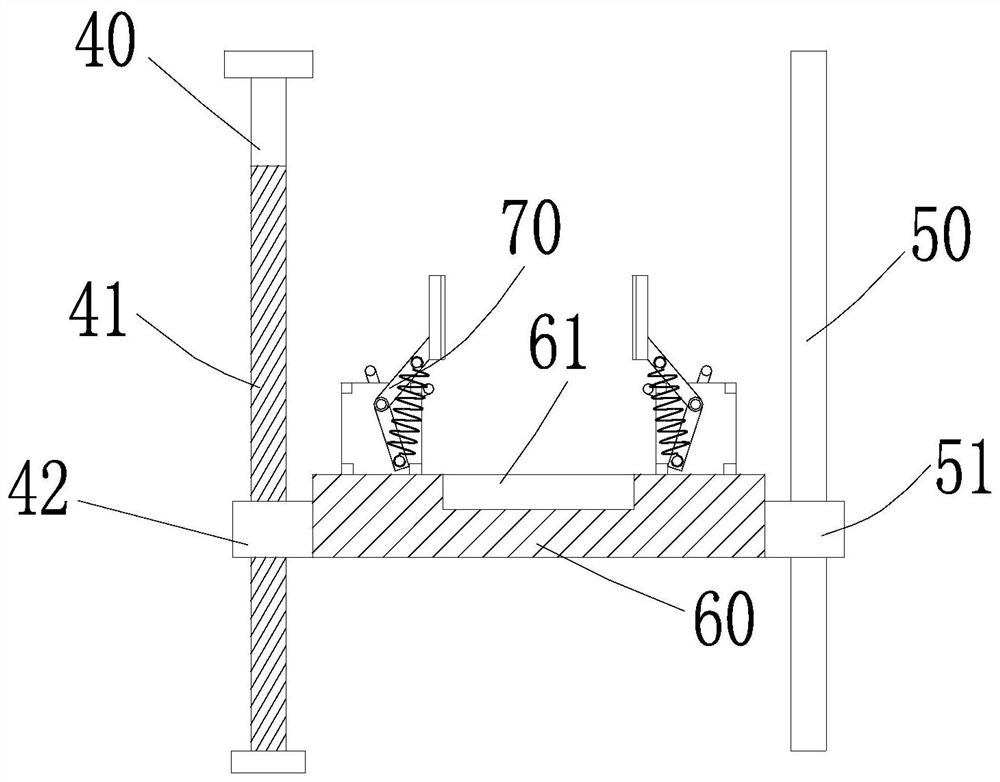

[0033] The housing 20, the housing 20 is arranged on the upper end of the base 10, the front side of the housing 20 is provided with an openable door 21, the housing 20 is vertically provided with a first rod body 40 and a second rod body 50, the first rod body 40 passes through The bearing assembly is rotatably connected to the inner top wall of the housing 20, the first rod body 40 is provided with a threaded section 41, the threaded section 41 is provided with a first moving seat 42, and the second rod body 50 is movably socketed with a second moving seat 51;

[0034] The carrying plate 60 is horizontally arranged inside the housing 20 and is located between the first rod body 40 and the second rod body 50 . One end of the carrying plate 60 is connected to the first moving seat 42 and the other end is connected to th...

Embodiment 2

[0037] On the basis of Embodiment 1, an exhaust port 23 is provided on the left and right sides of the top of the housing 20, an air inlet 22 is provided on the left and right sides of the bottom, and a first screen 24 is arranged on the air inlet 22; inside the housing 20 A support plate is provided, and a second screen 25 is horizontally arranged on the support plate, and the second screen 25 is located above the air inlet 22;

[0038] The top of the housing 20 is provided with a conical roof 30; the inner wall of the housing 20 is provided with a conduit 26, and the conduit 26 goes out of the housing 20 for passing through the wires in the transformer.

[0039]Specifically, the high-voltage electrical appliances will generate heat during operation, and gradually heat the air inside the casing 20, the air with a higher temperature in the casing 20 rises and is discharged from the top exhaust port 23, and the air with a lower temperature enters through the bottom air inlet 22 ...

Embodiment 3

[0041] On the basis of Embodiment 1 or Embodiment 2, the limit assembly 70 includes a vertical plate 71 arranged on the upper end of the bearing plate 60, and a rotating rod 72 is arranged on the vertical plate 71, and the rotating rod 72 passes through the vertical plate 71. Rod 72 is provided with one end rotating handle 75, and rotating handle 75 is provided with two groups of driving levers 751 that protrude forward, and the other end is hinged with first movable arm 73 and second movable arm 74, and first movable arm 73 extends upwards, and Connected with a butt plate 76, the top of the first movable arm is provided with a first fixed column 731 protruding forward, the second movable arm 74 extends downward, and the bottom of the second movable arm 74 is provided with a second fixed column protruding forward 741, the front side of the vertical plate 71 is provided with a tension spring 77, one end of the tension spring 77 is hooked on the first fixed column 731, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com