Display assembly and display device

A technology for display components and display devices, which is applied to identification devices, electrical components, electrical solid devices, etc., can solve problems such as occupying external space, achieve narrow frame design, reduce processing procedures and costs, and save processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

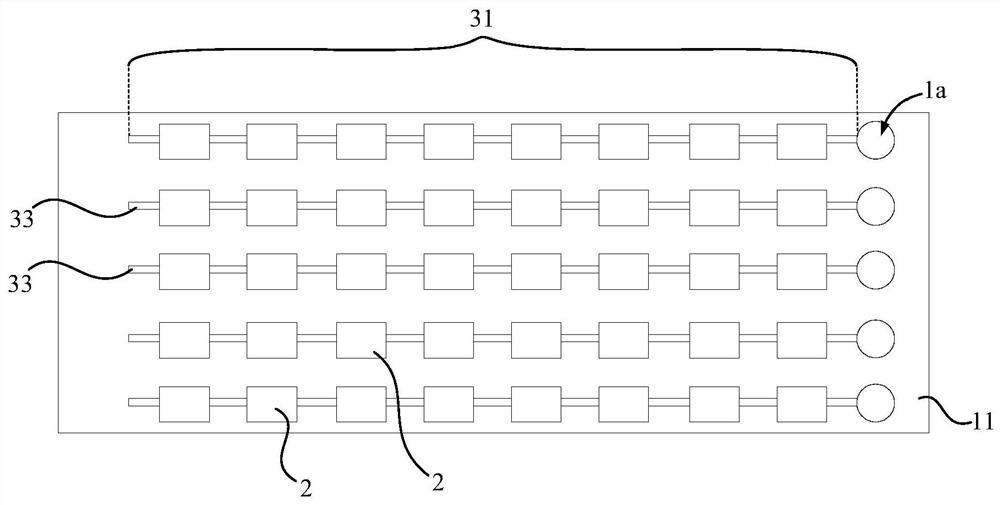

[0060] Such as Figures 1 to 3 As shown, each channel 1a provided on the glass substrate 1 is a through-hole structure, and a plurality of through-hole structures are disposed adjacent to the outer wall of the glass substrate 1 .

[0061] In this embodiment, each channel 1a is designed as a through-hole structure, and the through-hole structure may be a circular hole or an oval hole, so as to facilitate the processing of the through-hole structure. The glass substrate 1 can be a square structure, and the glass substrate 1 has four outer sidewalls arranged in pairs. A plurality of through hole structures can be arranged adjacent to the same outer sidewall of the glass substrate 1, or can be arranged adjacent to different outer sidewalls respectively. By arranging a plurality of through-hole structures adjacent to the outer wall of the glass substrate 1, each through-hole structure will be located at the edge of the glass substrate 1, so that on the basis of realizing the arrang...

no. 2 example

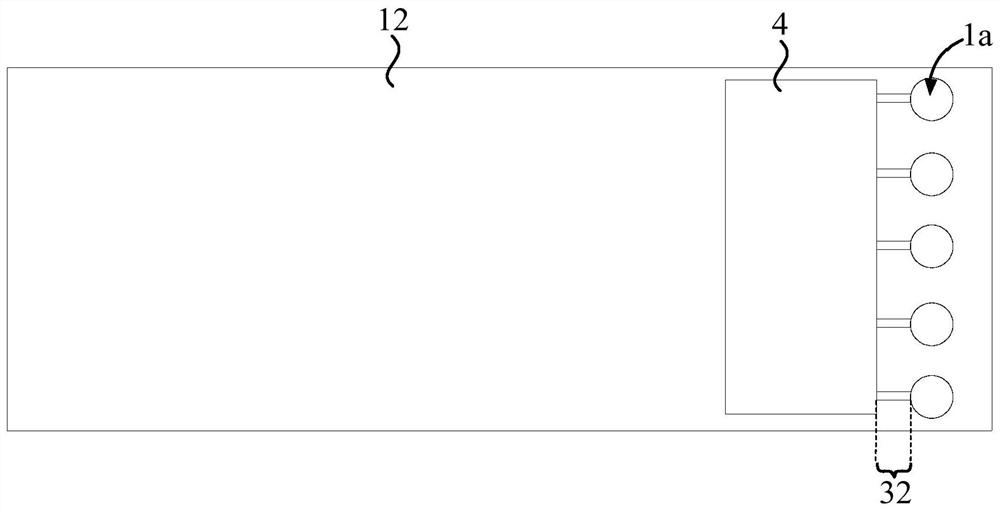

[0063] combine figure 2 , Figure 5 as well as Figure 7 As shown, each channel 1 a provided on the glass substrate 1 is a notch structure, and each notch structure is provided on the outer wall of the glass substrate 1 .

[0064] In this embodiment, each notch structure is opened on the outer sidewall of the glass substrate 1 , and each notch structure is disposed through the first loading surface 11 , the second loading surface 12 and the outer sidewall of the glass substrate 1 . The conductive layer 13 is provided on the inner sidewall of the notch structure, and is used to realize the electrical connection between the driving circuit 3 and the driving module 4 . By designing the channel 1a as a notch structure and setting each notch structure on the outer wall of the glass substrate 1, on the basis of realizing the arrangement of a plurality of light-emitting elements 2 and driving lines 3, the number of holes in each through hole of the glass substrate 1 can be reduced...

no. 3 example

[0070] Such as Figure 8 As shown, the glass substrate 1 is a square structure, the glass substrate 1 has two first sides 14 and two second sides 15, and the first sides 14 and the second sides 15 are alternately connected; the channel 1a includes a plurality of The first channel 1a1 and the plurality of second channels 1a2, the inner wall of each first channel 1a1 and the inner wall of each second channel 1a2 are provided with a conductive layer 13, and each conductive layer 13 is electrically connected to the drive module 4; A channel 1a1 is adjacent to a first side 14 and arranged at intervals along the extending direction of the first side 14; a plurality of second channels 1a2 is adjacent to a second side 15 and arranged at intervals along the extending direction of the second side 15 The driving circuit 3 includes a plurality of scanning lines 34 and a plurality of data lines 35 arranged on the first carrier surface 11, and each data line 35 is connected to a plurality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com