Strip steel surface image acquisition device for defect identification and use method thereof

A technology of surface image and acquisition device, which is applied in measurement device, optical testing of flaws/defects, material analysis by optical means, etc., can solve the problems of damaged strip surface image acquisition device, broken strip, strip damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

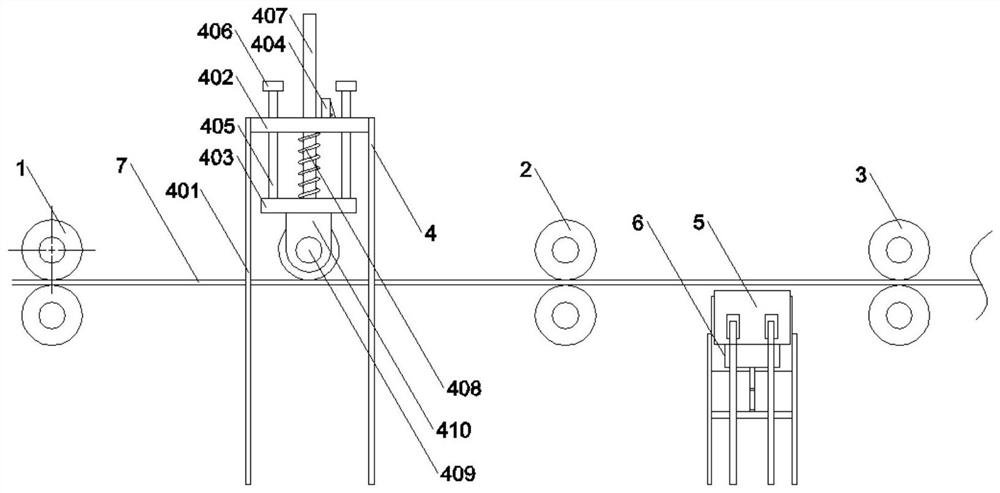

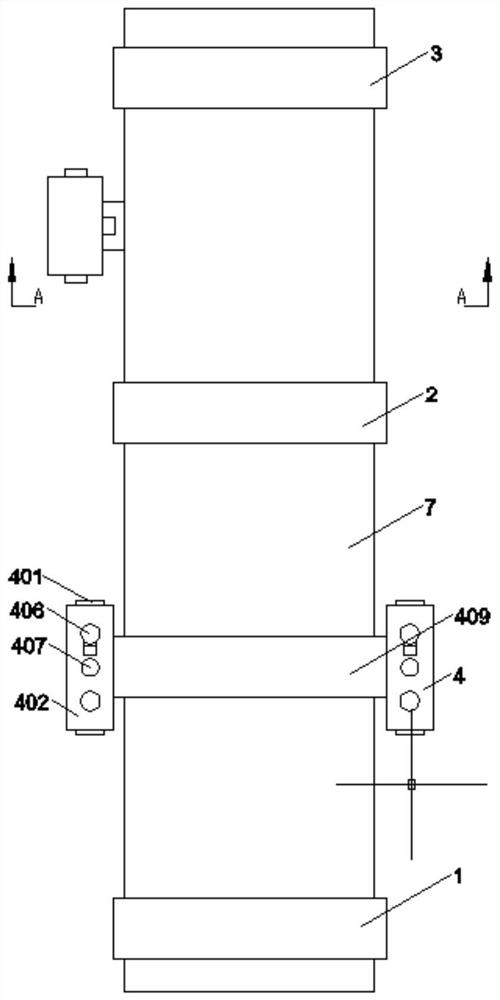

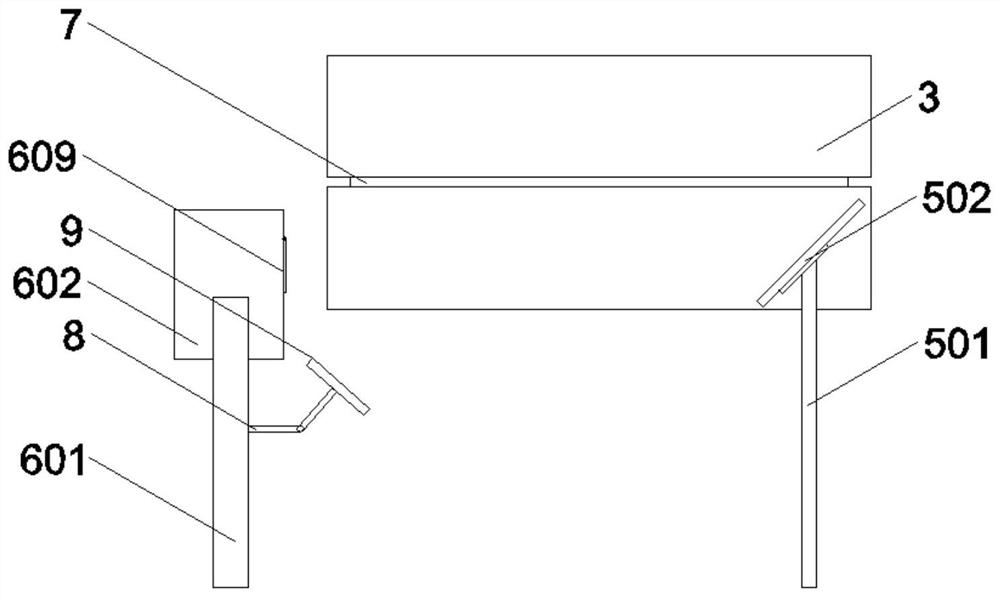

[0020] see Figure 1-Figure 5 , the present invention provides the following technical solutions: a strip surface image acquisition device for defect identification, including a pressure roller group one 1, a pressure roller group two 2, a pressure roller group three 3, the pressure roller group one 1, pressure roller group Roller group two 2 and pressure roller group three 3 are rollingly connected with strip steel 7, and the upper side of the strip steel 7 between the pressure roller group one 1 and pressure roller group two 2 is fixedly installed with a tension stabilization mechanism 4, so The tension stabilization mechanism 4 includes a leg one 401, the upper side of the leg one 401 is fixedly connected to both side end surfaces of a fixed plate 402, and a guide rod 405 and a slide rod 407 are slidably installed on the fixed plate 402, so The top surface of the fixed plate 402 is fixedly equipped with a travel switch 404, the top end of the guide rod 405 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com