Large pipe shed guide wall structure of underground excavation tunnel and construction method of large pipe shed guide wall structure

A technology of large pipe shed and guide wall, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve problems such as difficulty in ensuring horizontal angle, poor overall stability, and long drilling time, so as to ensure construction quality and reliability , increase the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

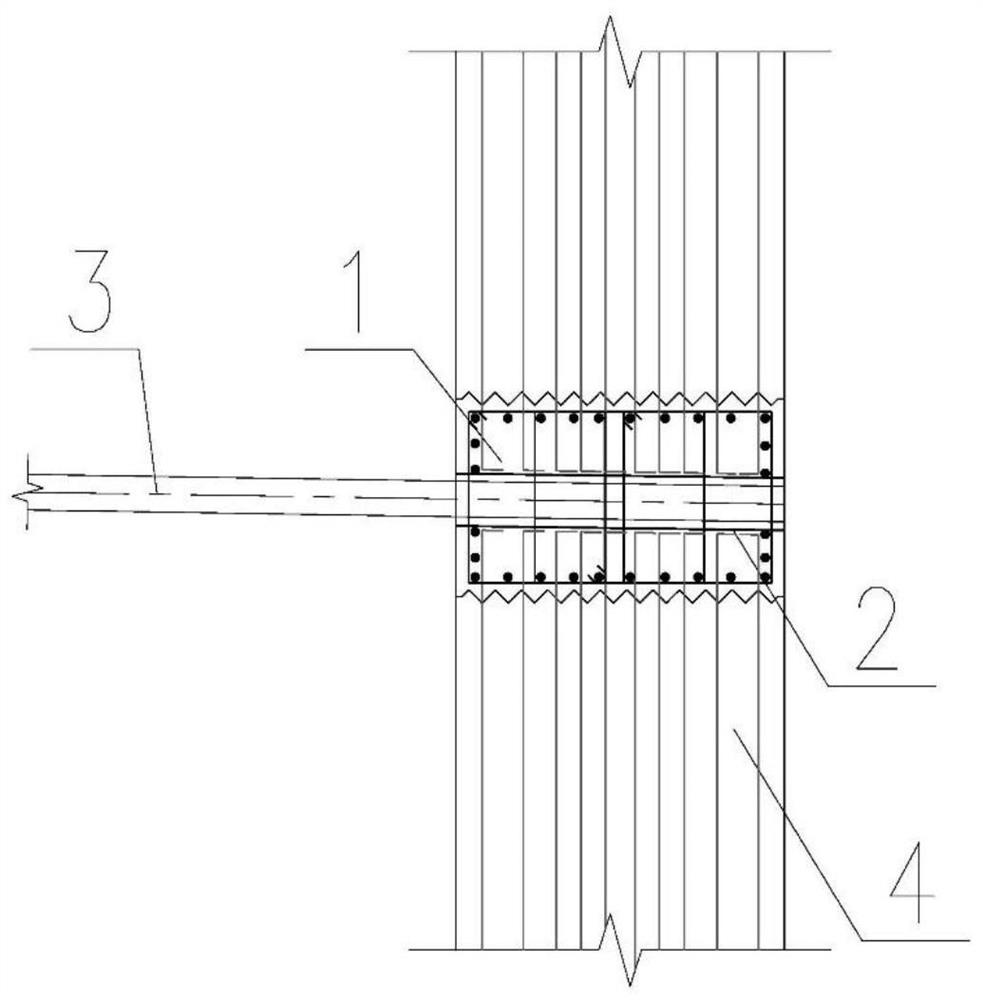

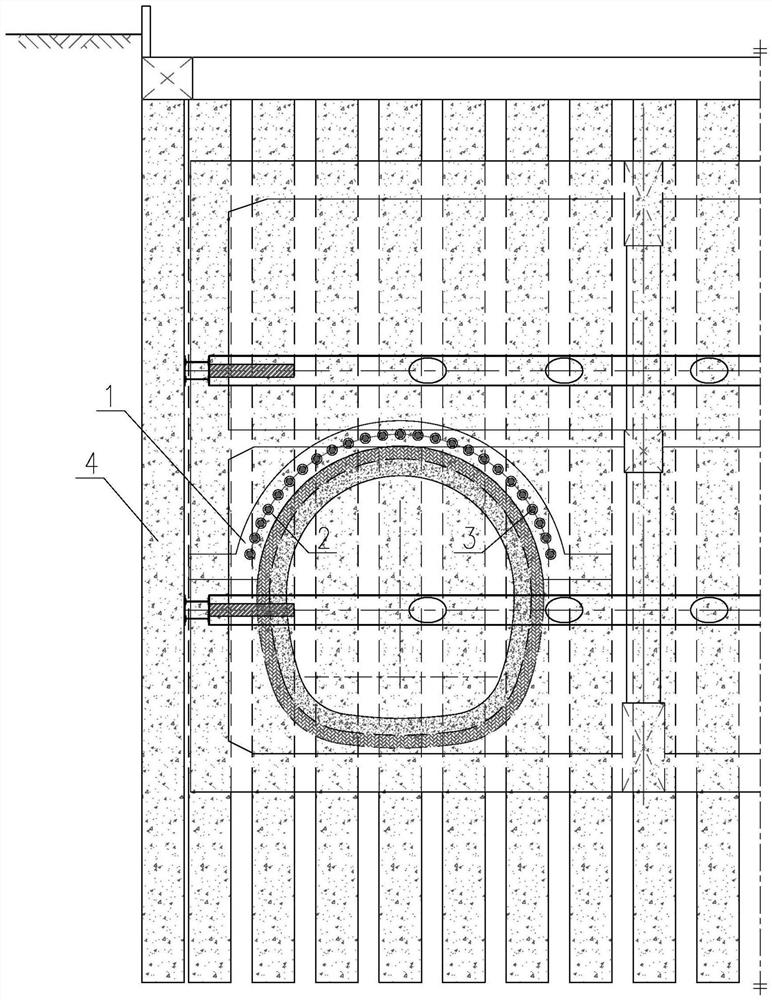

[0033] The large pipe shed guide wall structure of the underground excavation tunnel adopted in this embodiment includes a guide wall 1 located outside the entrance of the underground excavation tunnel, and large pipe shed pre-buried casings 2 arranged at circumferential intervals along the arch portion of the inner edge of the guide wall 1. The large pipe shed pre-buried casing 2 passes through the guide wall 1 longitudinally, and the large pipe shed 3 is constructed from the large pipe shed pre-buried casing 2 to the bedrock at the top of the excavated tunnel body; the guide wall 1 and the open cut structure enclosure The piles 4 are nested, the width of the guide wall 1 is the same as the diameter of the open-cut structure enclosure pile 4, and the open-cut structure enclosure pile 4 is anchored into the main reinforcement of the open-cut structure enclosure pile. The poured concrete makes the guide wall 1 and the large pipe shed pre-set The buried casing 2, the large pipe s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com