Pile forming method for jet grouting pile in flowing water sand layer

A technology of rotary jetting and piling, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problem of passive water flushing, taking away, leakage of foundation pit, water-stop curtain failing to stop water and interception Groundwater and other issues to achieve the effect of improving the success rate and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

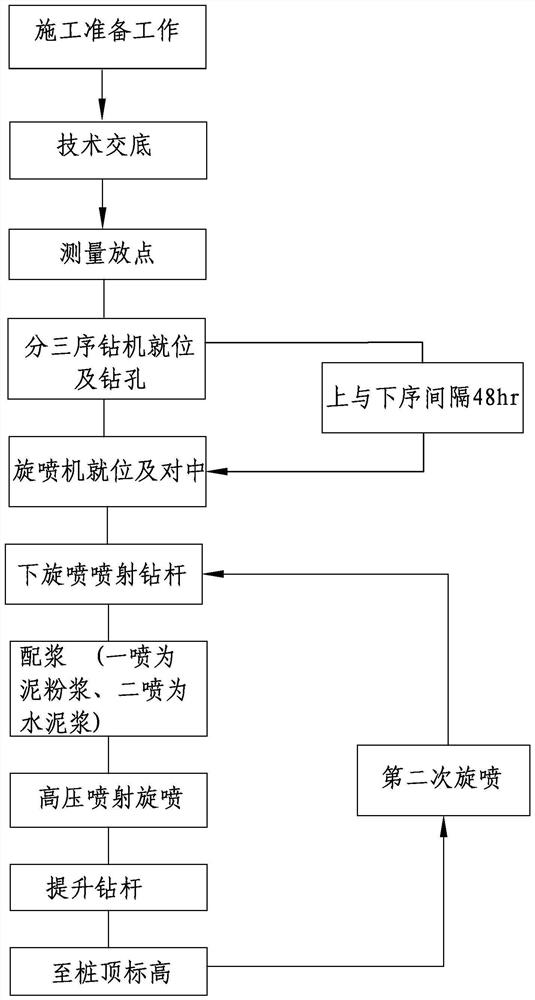

[0027] see figure 1 , the present embodiment relates to a pile-forming method of jet-jet piles in dynamic water sand layers, comprising the following steps:

[0028] Construction preparation and technical disclosure: Before construction, the laying of temporary construction, water and electricity, equipment, pipelines, etc. required for construction should be completed. During the construction process, attention should be paid to the following technical requirements: single-pipe jet grouting should be used for jet grouting piles after the foundation pit has been excavated, and double-pipe jet jet jetting can be used for jet grouting piles when the foundation pit has not been excavated. It is 0.7MPa, because when using compressed air, the excavated foundation pit will be flooded with slurry, and the unfavorable factors will affect the safety of the foundation pit. Therefore, the excavated foundation pit should use single-tube rotary grouting piles; Ensure that every employee a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com