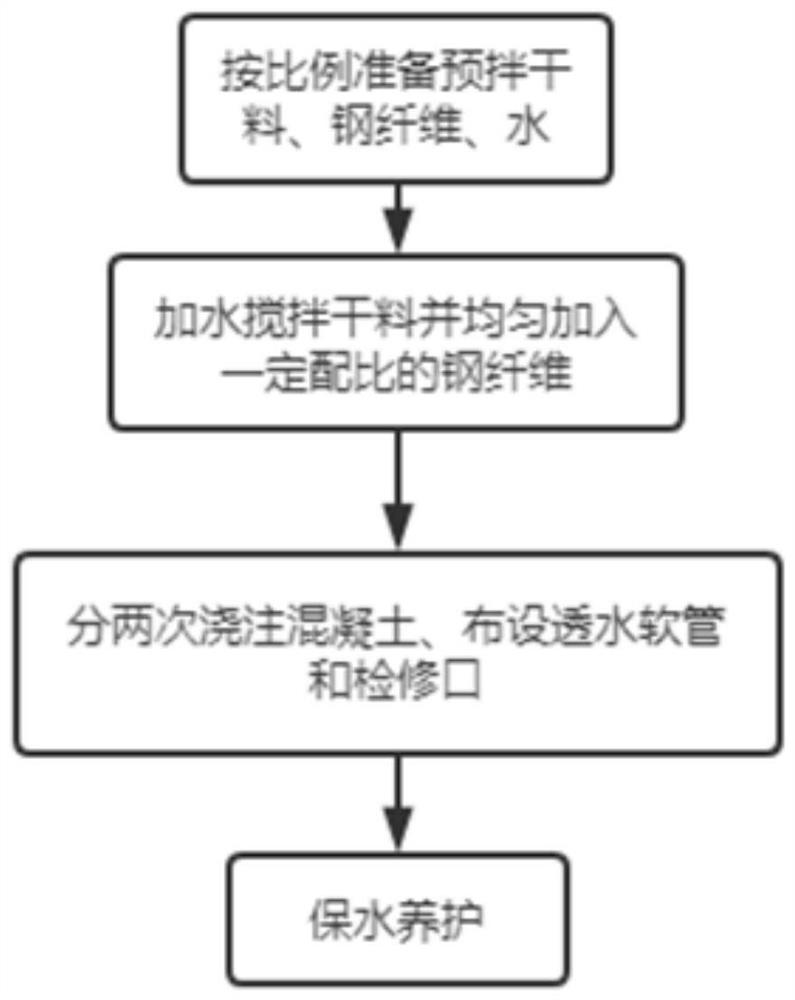

Tramcar track construction method with high-performance cement concrete as lap joint material

A technology for cement concrete and trams, which is applied in the direction of roads, roads, road repairs, etc. It can solve problems such as spalling and cracking of the joint and rail, easy cracks at the joint of the road surface, and affect the stability of the joint, so as to achieve excellent durability performance, avoid electric corrosion phenomenon, improve driving safety and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

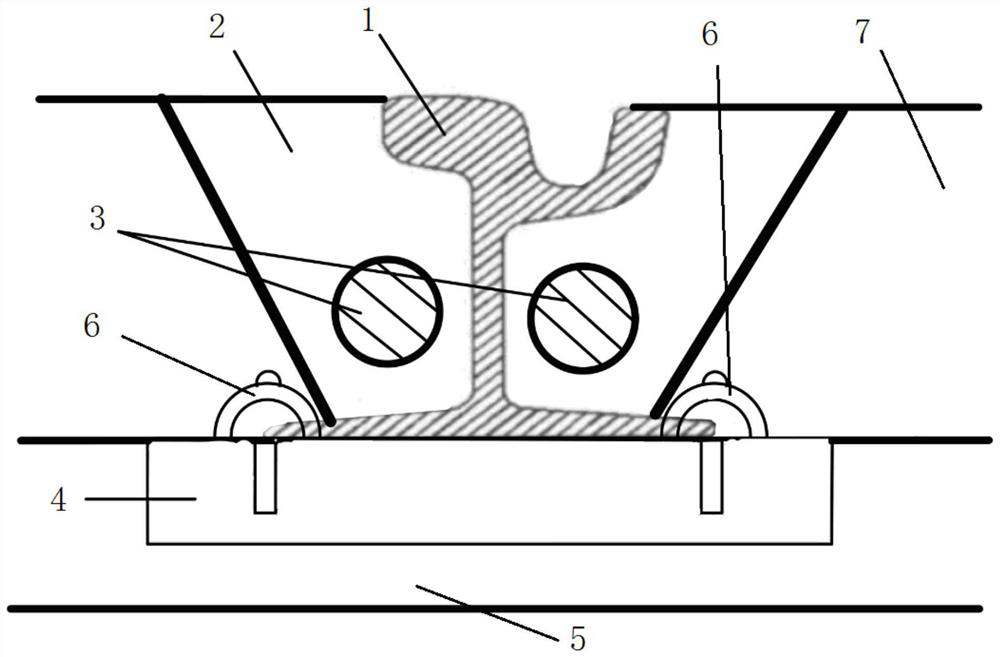

[0051] Such as Figure 1 to Figure 3 As shown, the tramway track construction method using high-performance cement concrete as the lapping material; including the multi-section grooved steel rail 1 arranged on the ballast bed 5;

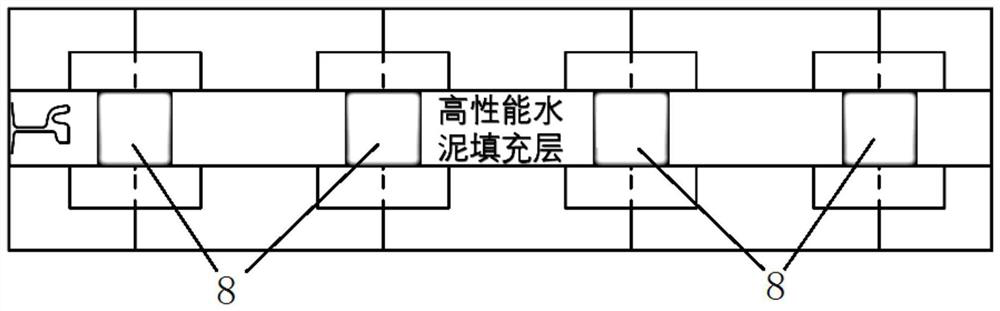

[0052] Between both sides of each grooved steel rail 1 and the pavement 7 is a filling area 2 filled with high-performance cement concrete;

[0053] Each filling area 2 is a groove structure with a trapezoidal cross section, and a water-permeable hose 3 extending along the length direction of the corresponding grooved steel rail 1 is provided inside;

[0054] The width of the groove structure corresponding to the upper opening position is greater than the width corresponding to the bottom position, and the cross section is an inverted trapezoid whose upper part is wider than the lower part;

[0055] The joint surface between each filling area 2 and the corresponding pavement 7 is at an angle of 60±5 degrees with the horizontal plane;

[0056] Const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com