Copper-based graphene aerogel composite catalyst, gas diffusion electrode and application

A graphene airgel and gas diffusion electrode technology, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor catalyst activity, low selectivity, and poor catalyst stability, so as to improve activity and selectivity, improve Favorable effect on selectivity, activity, and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In a second aspect, the embodiments of the present invention also provide a method for preparing a copper-based graphene airgel composite catalyst, comprising the following steps:

[0039] (1) Dissolve copper nitrate trihydrate in ethylene glycol, stir and heat, and prepare a copper salt precursor solution, which is designated as solution A.

[0040] (2) Disperse the graphene airgel powder in ethylene glycol, and ultrasonically treat it to prepare a uniform suspension, which is denoted as dispersion B.

[0041] (3) Add the dispersion B to the solution A and stir to obtain a mixed solution. The mixed solution is placed in a reaction kettle for solvothermal reaction, the product is naturally cooled, filtered, washed, dried and ground to obtain a catalyst.

[0042] In the preparation process of the above copper-based graphene airgel composite catalyst, copper nitrate trihydrate and graphene airgel were dissolved in ethylene glycol respectively, and then the ethylene glyco...

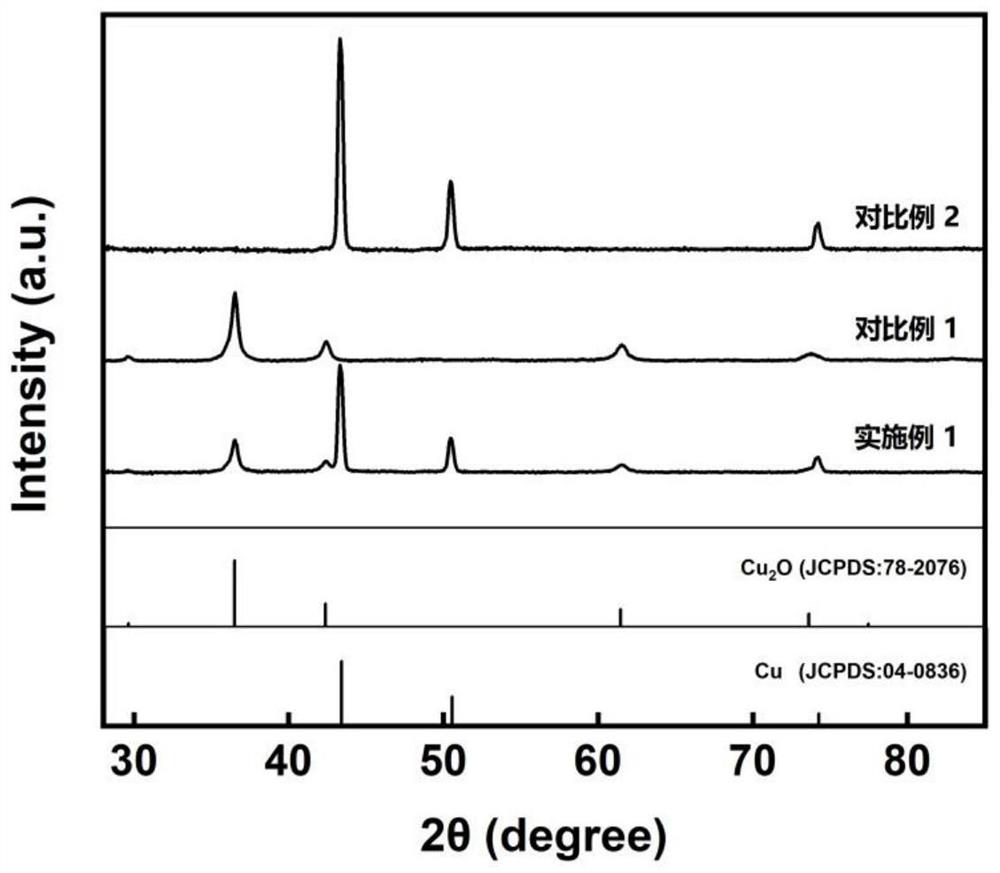

Embodiment 1

[0065] A copper-based graphene airgel composite catalyst, which includes graphene airgel and nano-copper oxide loaded thereon, the preparation method of the catalyst is a solvothermal method, and the specific steps are as follows:

[0066] (1) Ultrasonically disperse graphene oxide in an aqueous solution, freeze-dry it, and then reduce it to obtain a graphene airgel material.

[0067] (2) Dissolve 0.80 g of copper nitrate trihydrate in 200 mL of ethylene glycol, stir at 100° C. for 1 h, and prepare a copper precursor solution, which is designated as solution A.

[0068] (3) Disperse 0.20 g of graphene airgel in 100 mL of ethylene glycol, and ultrasonically treat it for 1 hour to prepare a uniform suspension, which is designated as dispersion B. Add dispersion B dropwise to solution A and stir for 1 h.

[0069] (4), put the mixed solution in the reactor, which is a 500mL hydrothermal synthesis reactor with a stainless steel jacket and a polytetrafluoroethylene liner, put the r...

Embodiment 2

[0082] A copper-based graphene airgel composite catalyst, which includes graphene airgel and nano-copper oxide loaded thereon, the preparation method of the catalyst is a solvothermal method, and the specific steps are as follows:

[0083] (1) Ultrasonically disperse graphene oxide in an aqueous solution, freeze-dry it, and then reduce it to obtain a graphene airgel material.

[0084] (2) Dissolve 0.80 g of copper nitrate trihydrate in 200 mL of ethylene glycol, stir at 100° C. for 1 h, and prepare a copper precursor solution, which is designated as solution A.

[0085] (3) Disperse 0.20 g of graphene airgel in 100 mL of ethylene glycol, and ultrasonically treat it for 1 hour to prepare a uniform suspension, which is designated as dispersion B. Add dispersion B dropwise to solution A and stir for 1 h.

[0086] (4), the mixed solution is placed in the reactor, which is a 500mL hydrothermal synthesis reactor with a stainless steel jacket and a polytetrafluoroethylene liner, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com