Full-automatic conveying line for shaping and processing chicken steaks

A fully automatic, conveyor line technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as low efficiency and achieve the effect of solving disposal problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

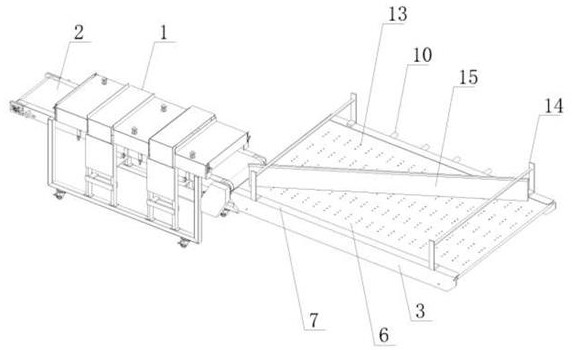

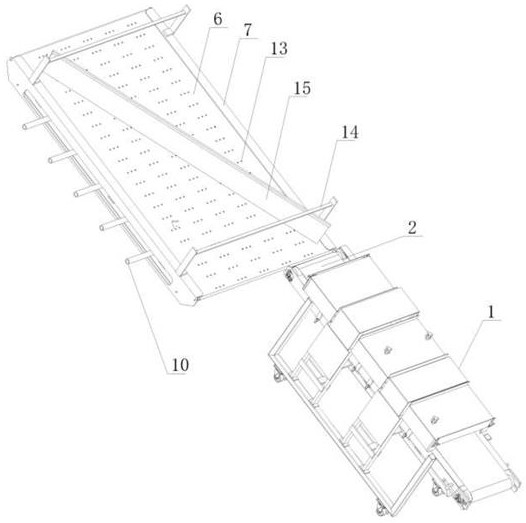

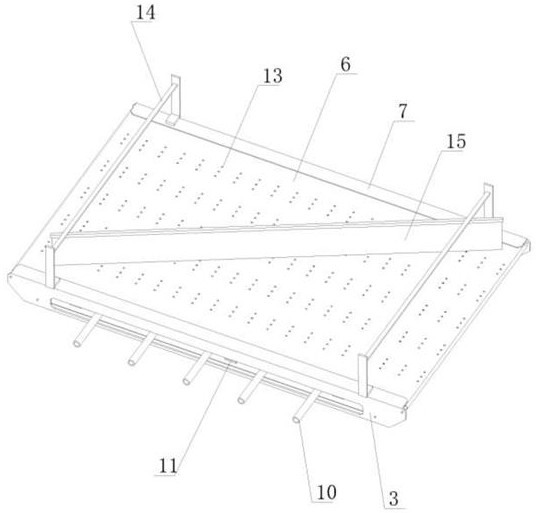

[0026] Example 1: A fully automatic conveyor line for plastic processing of chicken chops

[0027] Such as Figure 1-6 As shown, the fully automatic chicken slicer 1 is briefly described according to the prior art, including a belt conveyor 2, and a slicing mechanism is mounted on the top of the belt conveyor 2, and the chicken breast is transported by the belt conveyor 2, and the chicken breast is conveyed by the slicing mechanism. The chicken breast meat is sliced in multiple layers, and the sliced chicken slices are transported to the end by the belt conveyor 2. This conveyor line is exactly to be docked with the belt conveyor 2 end of full-automatic chicken slicer 1.

[0028] The automatic conveying line includes machine boards 3 arranged left and right relative to the conveying direction, one of which is flush with one side of the belt conveyor 2 on the chicken slicer 1 .

[0029] Because the sliced chicken is relatively loose, the transfer of a higher drop will e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com