Multi-line material bonding machine device and implementation method thereof

A bonding machine and bonding technology, which is applied in the field of multi-line bonding machine devices, can solve the problems of slow efficiency, poor quality, and low production capacity, and achieve the effects of high bonding precision, fast bonding speed, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

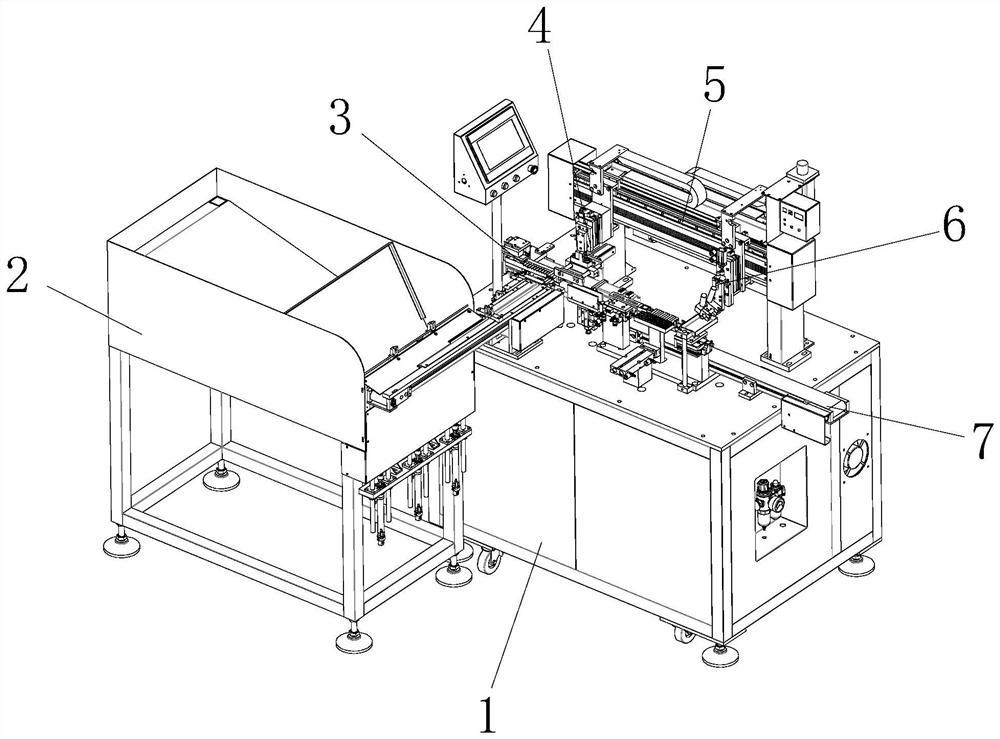

[0044] see Figure 1-9 , the present invention provides the following technical solutions: a multi-line adhesive machine device, including a frame 1, a manipulator 5 is connected above the frame 1, and a clamping mechanism 4 and a material bonding mechanism 6 are respectively connected to the output end of the manipulator 5 , the clamping mechanism 4 is located on one side of the sticking mechanism 6, and the top of the frame 1 is provided with a blanking mechanism 7 corresponding to the sticking mechanism 6 and an arrangement mechanism 3 corresponding to the clamping mechanism 4, and the frame 1 One side is provided with a feeding mechanism 2 corresponding to the arrangement mechanism 3, and the feeding mechanism 2, the arrangement mechanism 3, the clamping mechanism 4, the manipulator 5, the sticking mechanism 6 and the unloading mechanism 7 are all connected with the PLC controller signal.

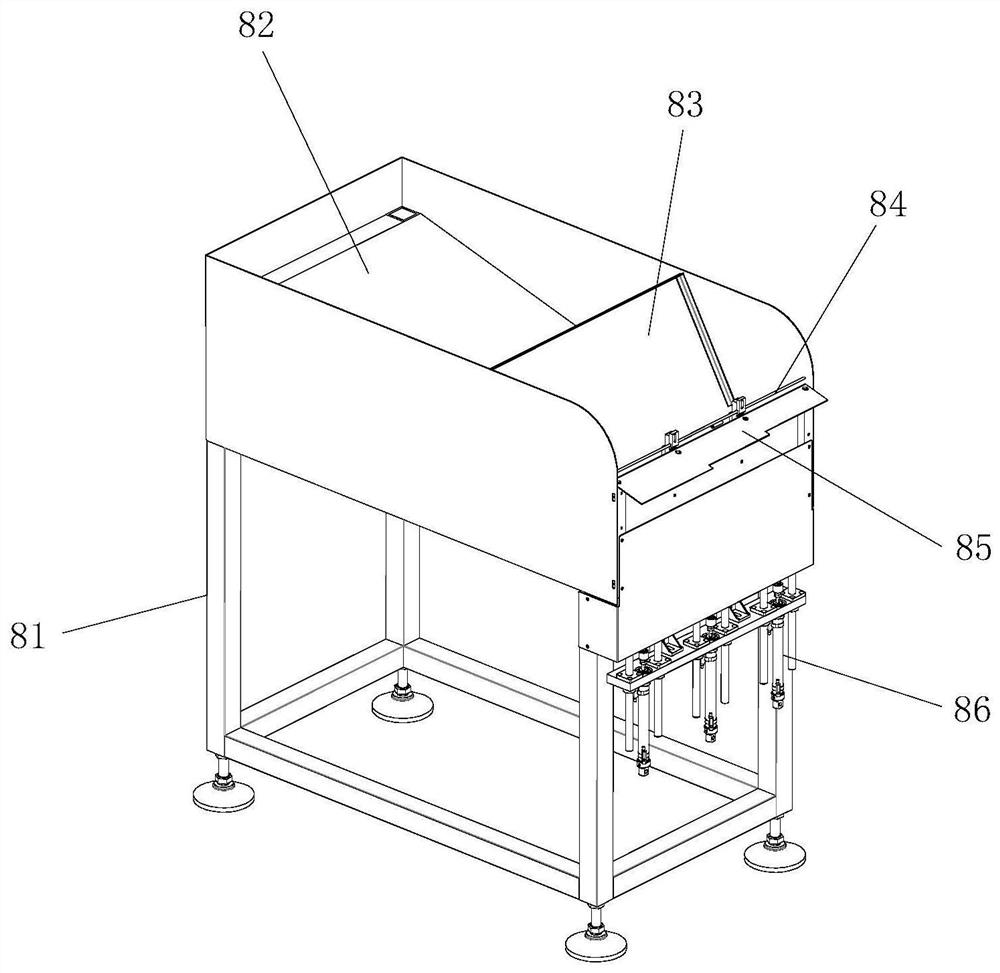

[0045]Specifically, the feeding mechanism 2 includes a feeding machine 8 and a feed...

Embodiment 2

[0068] see Figure 10 , the difference between this embodiment and Embodiment 1 is that: Specifically, two wrong material blocks 933 are provided on the wrong material component mounting seat 931. In this embodiment, three material troughs 935 are set as an example, one wrong material A material trough 935 is arranged on the material block 933 , two material troughs 935 are arranged on one material wrong block 933 , and a wrong material cylinder 934 corresponding to the two wrong material blocks 933 is provided below the wrong material component mounting seat 931 .

[0069] By adopting the above technical scheme, the feeding of single and double materials is realized; for circular materials, the upper material and the lower material are alternately bonded in dislocation, which can ensure the stability of the bonding. Therefore, in this embodiment, 10 The material is arranged into the lower layer material as an example. When two wrong material blocks 933 are fed at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com