Vacuum platform for printing machine and using method of vacuum platform

A technology for vacuum platforms and printing machines, applied to printing machines, rotary printing machines, screen printing machines, etc., can solve the friction damage on the surface of the PCB board, the offset of the printed position of the PCB board, and the contact surface between the PCB board and the steel mesh Inequality problems, to achieve the effect of ensuring printing quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

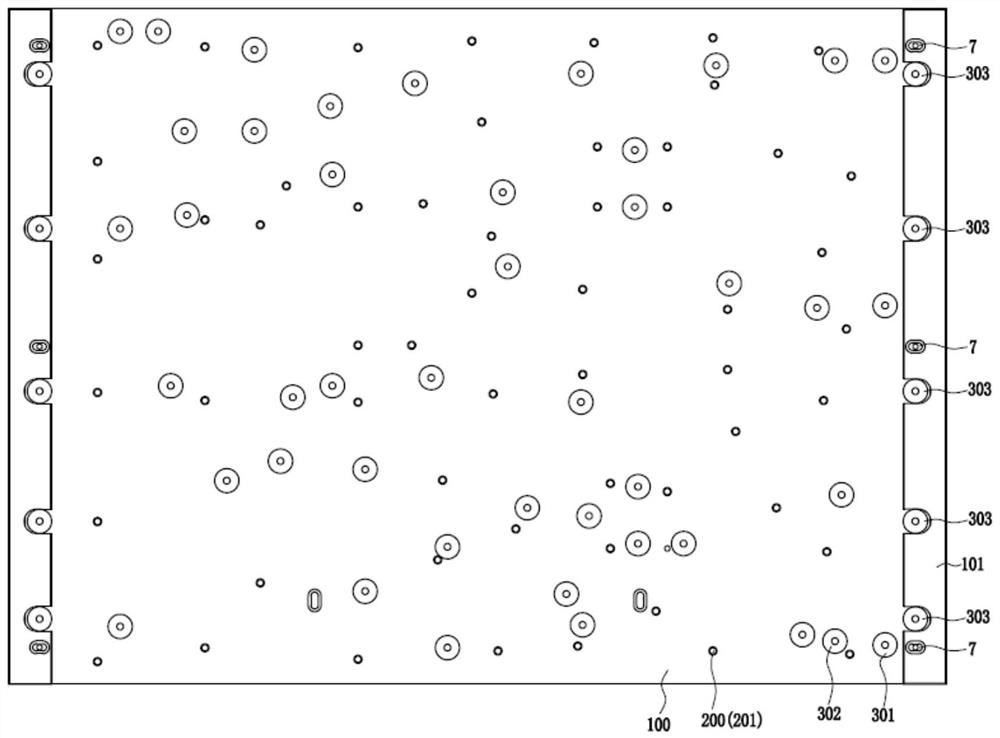

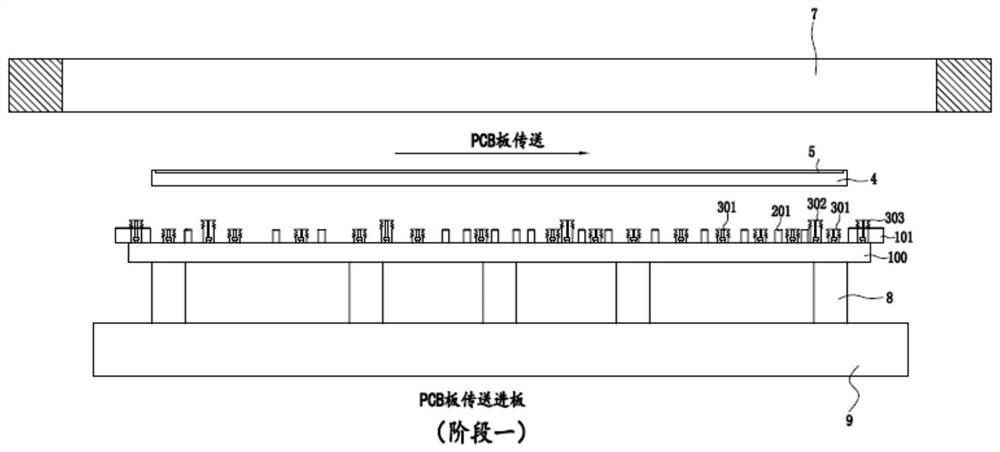

[0074] The supporting thimble 201 and the main platform 100 are integrally formed; in this embodiment, since the supporting thimble 201 and the main platform 100 can be made of the same material, during processing, the supporting thimble 201 and the main platform 100 It is processed into an integrated molding structure, which can facilitate processing and production on the one hand, so that the supporting thimble 201 and the main platform 100 do not need to be processed separately, and one-time molding can reduce processing time and improve processing efficiency; on the other hand, this can ensure that the supporting thimble 201 and the main platform The stability of the connection between 100 avoids the shaking of the supporting thimble 201 , so that the supporting thimble 201 can better support the PCB board 5 .

Embodiment 2

[0076] The bottom end of the support thimble 201 is fixed on the main body platform 100 by welding or riveting; in this embodiment, the support thimble 201 can be a commonly used standard thimble, so that the procurement sources are relatively abundant and the cost is low, and Welding and riveting processes are also mature processes in the industry, and their processing costs are also relatively low.

Embodiment 3

[0078] The main body platform 100 is provided with thimble mounting holes (not shown) having the same number as the supporting thimbles 201, the thimble mounting holes are adapted to the lower part of the supporting thimble 201, and the lower part of the supporting thimble 201 is inserted in the supporting thimble In the installation hole, and form transition fit or interference fit with the thimble installation hole; The support thimble 201 is plugged into the thimble mounting hole in a manner, and the support thimble 201 of the required height can be replaced according to the thickness of the tooling fixture 4 or the deformation amount of the bottom of the tooling fixture 4, so that the replacement of different support thimble 201 height requirements can be met.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com