Rolling type cylindrical hollow pier reinforcement cage binding jig frame

A steel cage and hollow pier technology, which is applied in the field of steel cage binding, can solve problems such as the inability to meet the requirements for steel cage binding of cylindrical hollow piers, and achieve the effects of improving convenience and safety, convenient operation, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the drawings and embodiments.

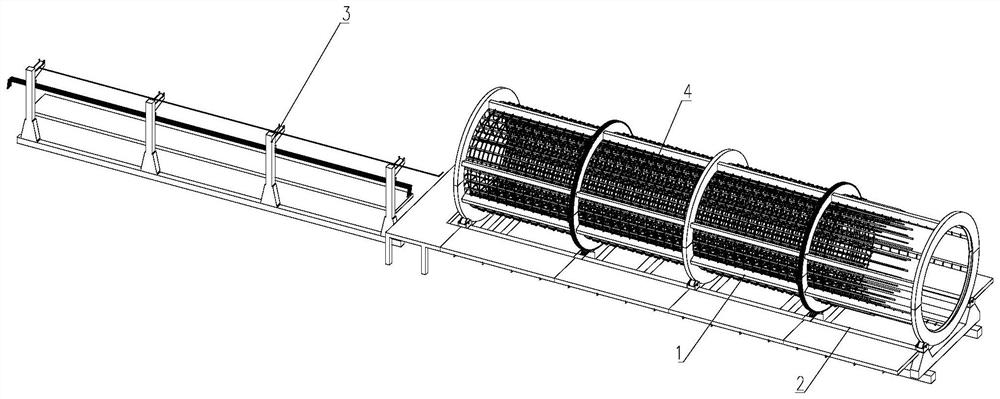

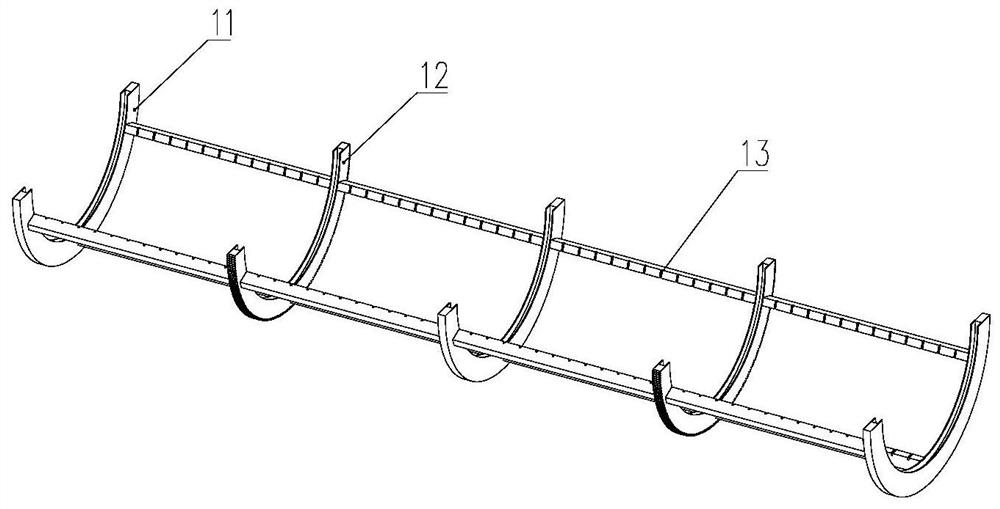

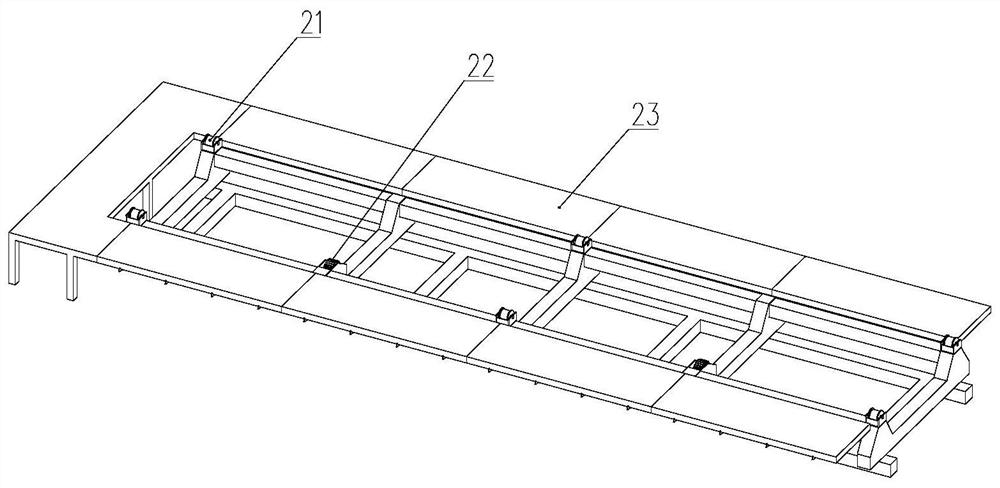

[0027] Such as Figure 1-4 As shown, the rolling cylindrical hollow pier reinforcement cage binding tire frame of this embodiment includes a reinforcement cage limiter, a base 2, a vertical reinforcement auxiliary threading mechanism 3 and an electric control system. The spacer of the steel cage is composed of two semicircular spacer bodies 1 spliced together, and the body of the spacer 1 includes a plurality of annular gear rails 12 arranged at intervals along the longitudinal direction of the steel cage 4, and a plurality of spacers along the steel bar. The hoop guide rails 11 arranged at intervals in the longitudinal direction of the cage 4 and the circumferentially arranged multiple limit beams 13 connecting the hoop racks and the hoop racks in series, the hoop racks 12 and the hoop guide rails 11 are alternately arranged, so The limiting longitudinal beam 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com