A kind of cast micro-dip coating batch production equipment for composite film

A kind of production equipment and batch processing technology, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve the problems such as poor coating effect, achieve good coating effect, improve coating effect, Guarantee the effect of the coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

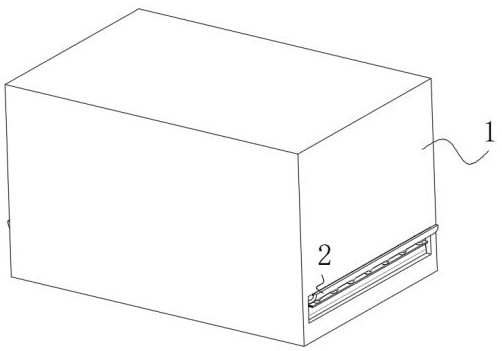

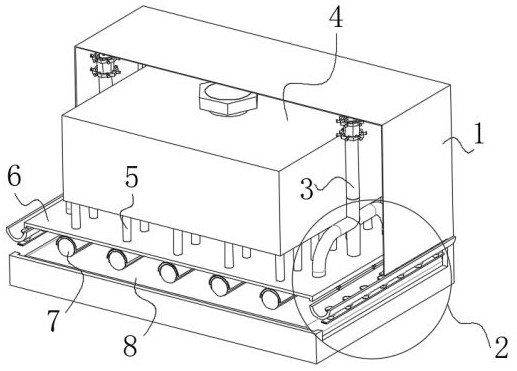

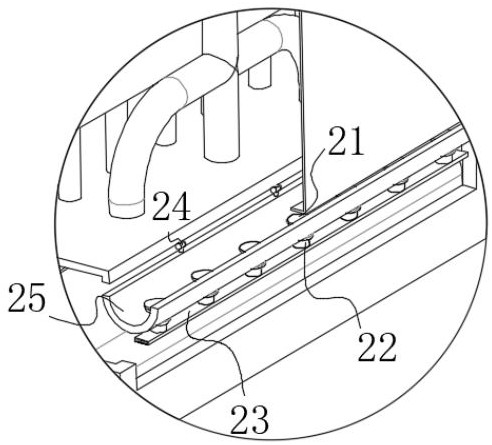

[0028] use Figure 1 - Figure 7 Micro-batch production casting dip coating apparatus of an embodiment of the composite film of the present invention will be described below.

[0029] like Figure 1 - Figure 7 Shown, a composite film of the present invention, a micro dip batch casting production apparatus comprising a housing 1, symmetrically disposed at both ends of the housing 1 there is a destination device 2 removing device 2, the composite film is provided Clear Clear carry for static, thus improving the composite film coating batches effect, provided inside the housing 1 is provided with a storage tank 4, the storage tank back surface of the housing 4 of the inner wall of the fixed connector 1, the bottom of the storage tank 4 is uniformly provided with a transfer pipe 5 is provided transfer tubes 5 the purpose is to ensure coating batch apparatus interior 7 may even contain top and bottom of the storage tank coating batches of raw material, the transfer tube 5 4 fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com