Workshop gas circulation device based on big data and control method thereof

A gas circulation and big data technology, applied in separation methods, combined devices, chemical instruments and methods, etc., can solve the problems of inability to seal, energy waste, unfavorable management, etc., to protect the environment and personnel health, and improve gas circulation. efficiency, reducing the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

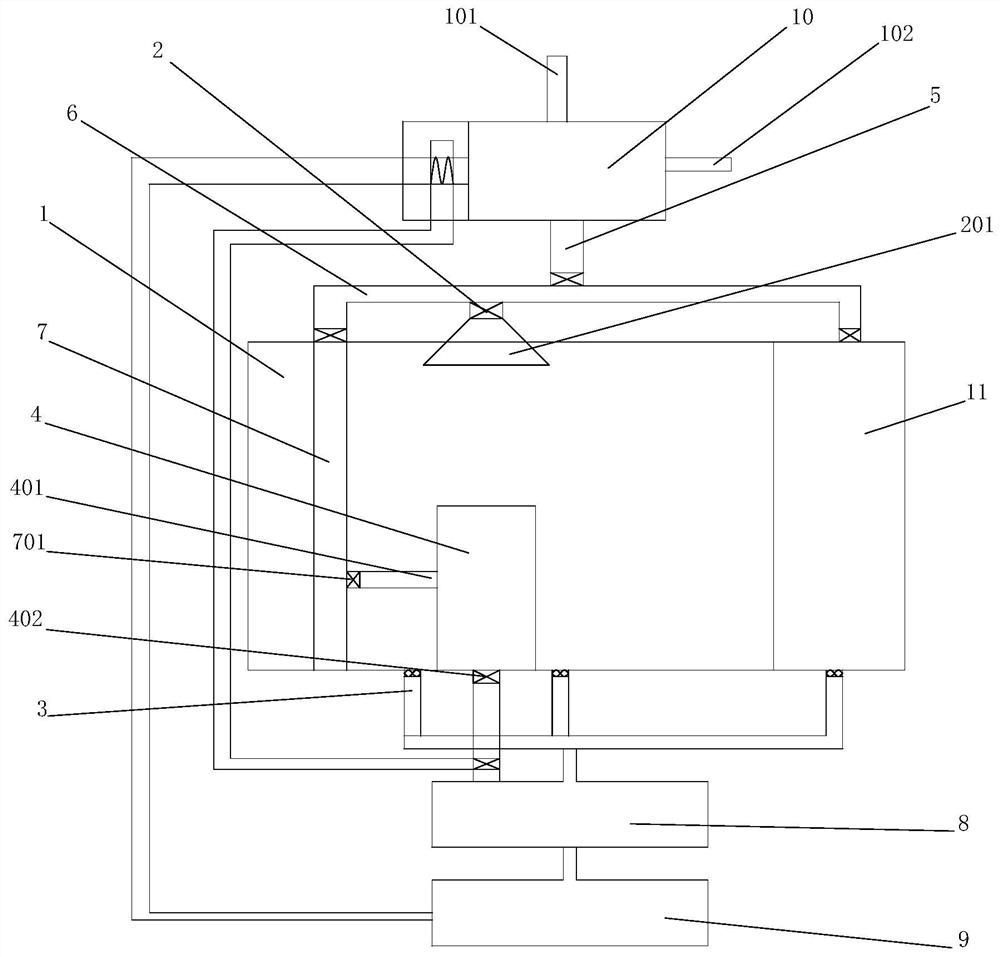

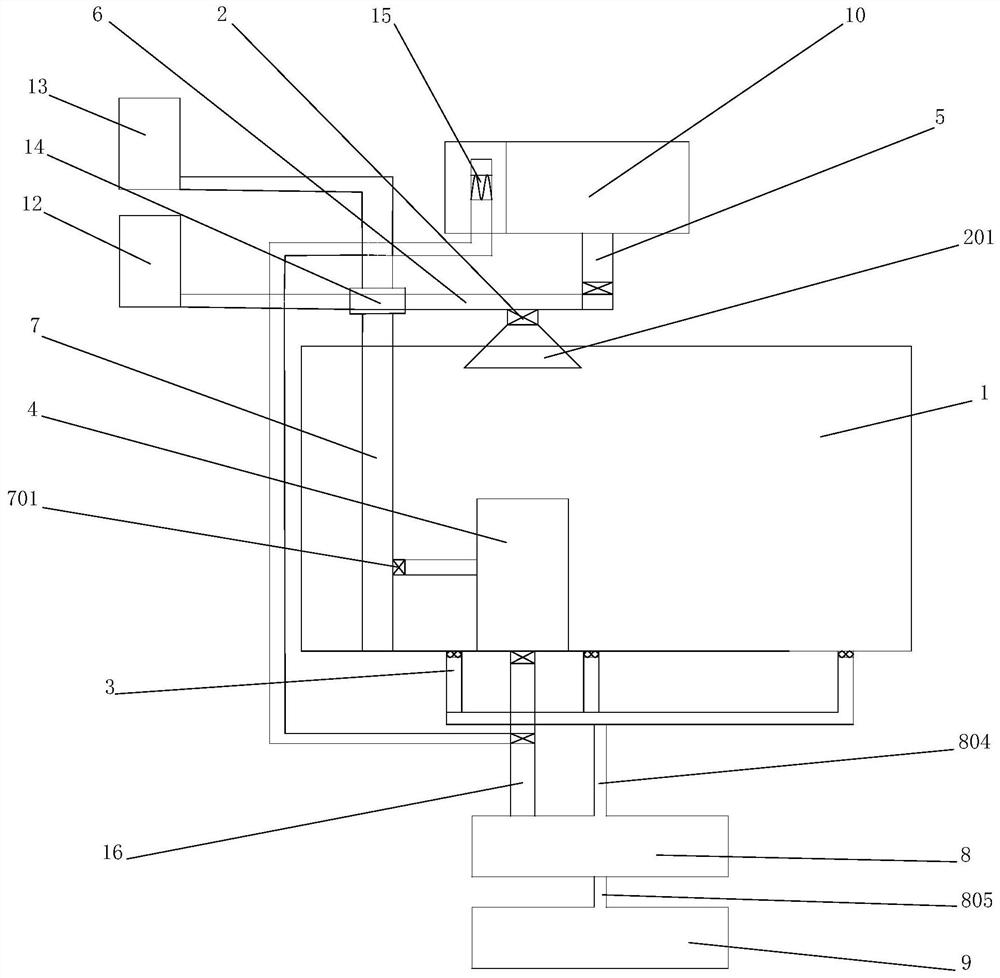

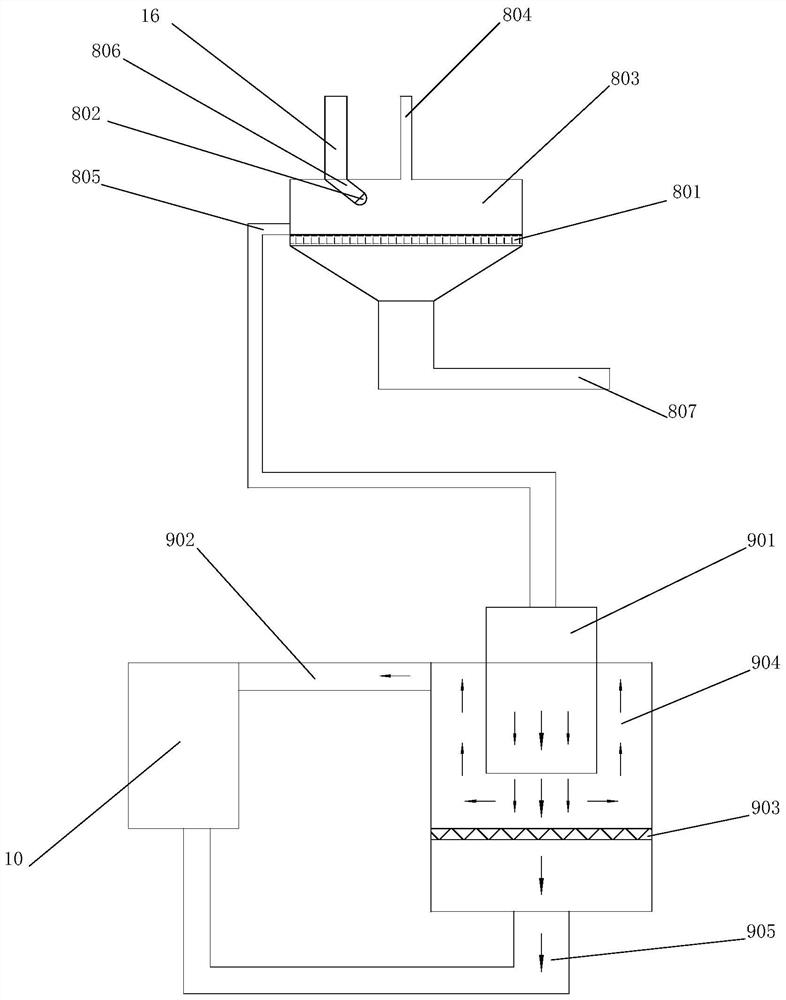

[0036] see Figure 1-5 , the present invention provides a technical solution: a workshop gas circulation device based on big data in the present invention, including a workshop body 1, an air inlet A2, an air outlet A3, three equipment bodies 4, a gas supply device, a gas storage tank 12 and a storage tank liquid tank13. The air supply device includes a main pipeline 5, branch pipelines 6, three branch pipelines 7, a purification mechanism 9, a filter mechanism 8, a constant temperature moisturizing mechanism 10 and a control system. Each branch pipe 7 supplies the device body 4 with the gas of the constant temperature and moisture retention mechanism, the gas of the gas storage tank 12 and the liquid of the liquid storage tank 13 . The inlet of the main pipeline 5 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com