Rice and wheat seed testing machine

A seed testing machine and rice-wheat technology, applied in the field of rice-wheat seed testing, can solve the problems of low efficiency, low accuracy, time-consuming and labor-intensive, etc., and achieve the effect of improving the threshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

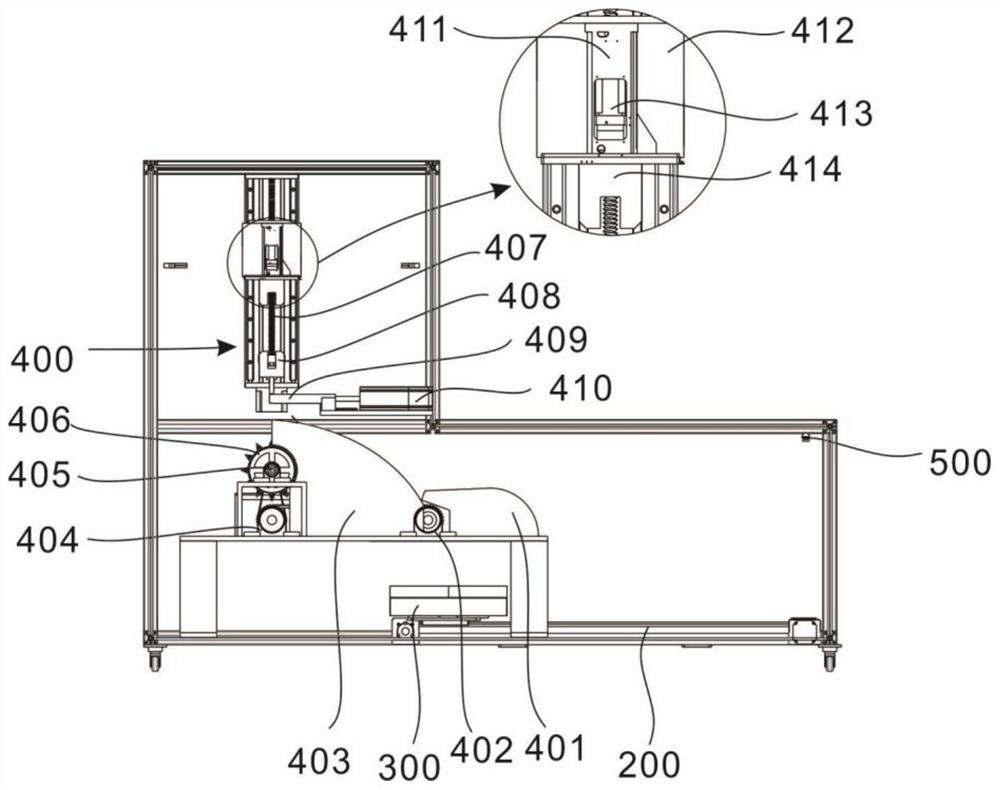

[0037] refer to Figure 1 to Figure 6 , this embodiment provides a kind of rice wheat seed tester, which can realize the length measurement, threshing, conveying and grain recovery of rice stalk or wheat stalk.

[0038] A kind of rice wheat testing machine, which includes,

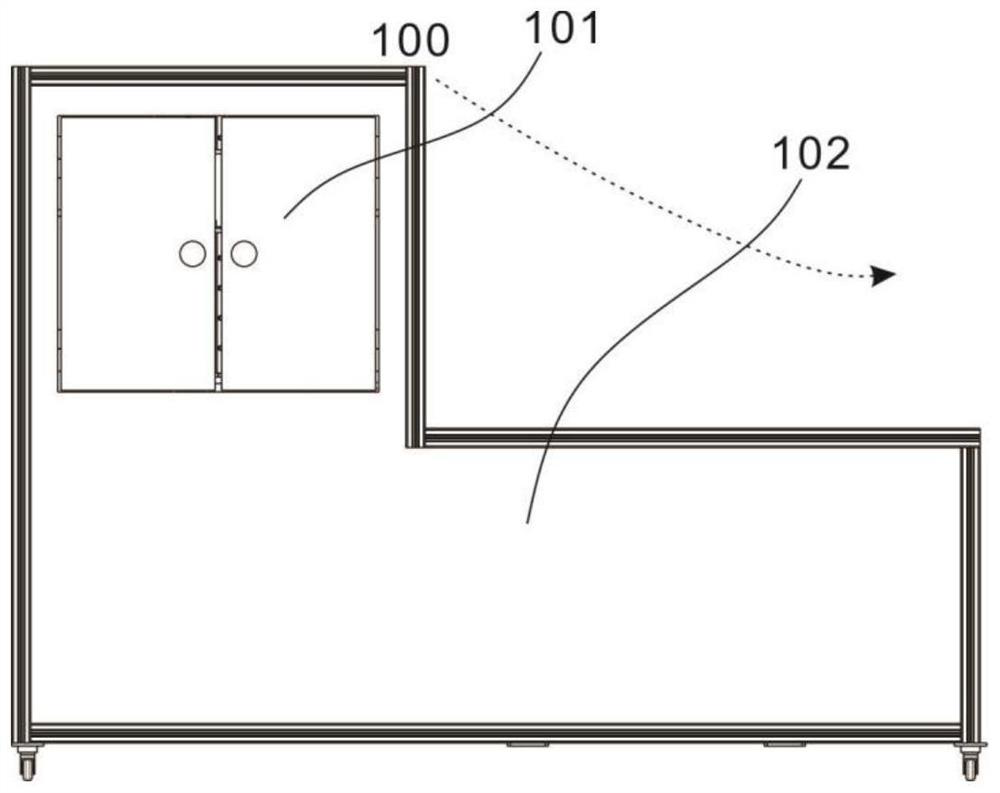

[0039] The installation assembly 100, the installation assembly 100 includes a test box 102 with a cavity, and the front end of the test box 102 is connected with a door body 101 that can be opened and closed;

[0040] Clamp the threshing assembly 400, the clamping threshing assembly 400 includes a fixed frame 434 and a support plate 430 fixed in the experimental box 102, the fixed frame 434 is connected with a first holder 414 that can move in the height direction, and the support plate 430 Connected to the second clamper 408 that can reciprocate in the horizontal direction, when the first clamper 414 and the second clamper 408 clamp the rod at the same time, the second clamper 414 on the first clamper 4...

Embodiment 2

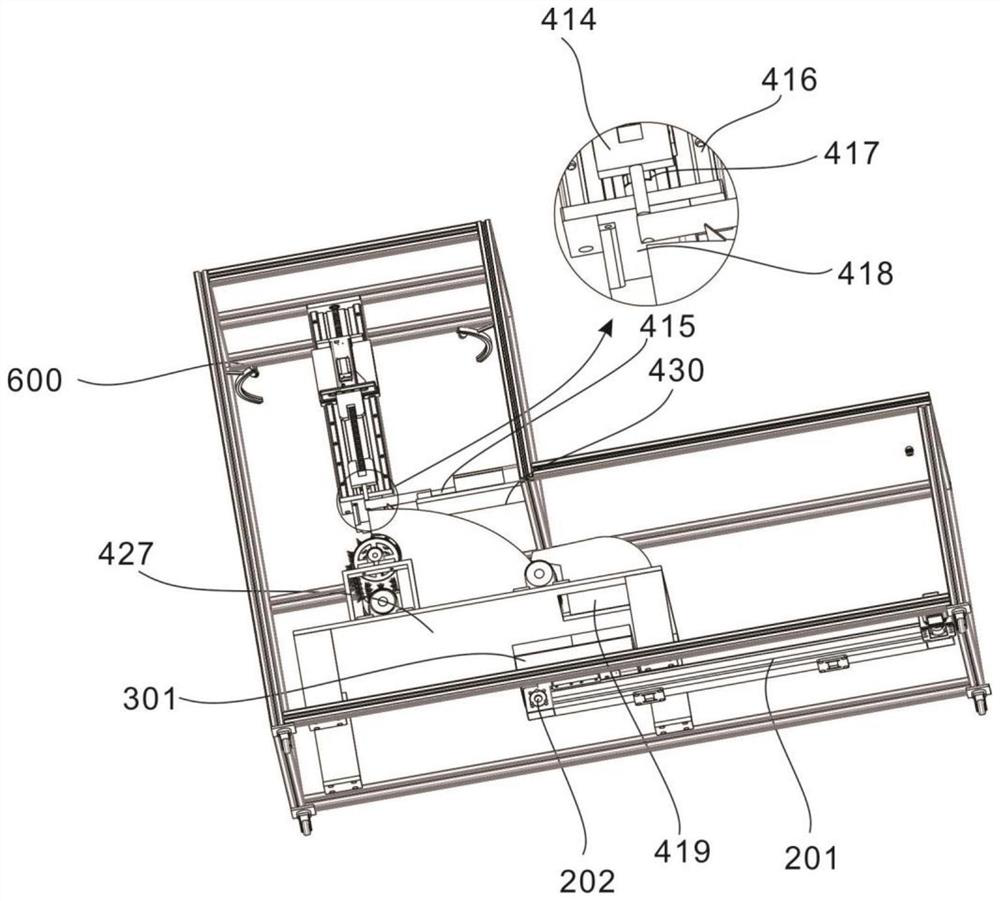

[0051] refer to Figure 6 ~ Figure 8 , is the second embodiment of the present invention, and this embodiment provides a kind of rice wheat testing machine, and it can realize the separation of shriveled grain and solid grain.

[0052] The recovery assembly 300 also includes a lower hopper 303 fixed on the connecting frame 427, the upward end of the lower hopper 303 has a lower material opening 307 covering the discharge opening 419, the bottom of the lower hopper 303 has a lower material opening 308, and the moving motor 206 Set away from the connecting frame 427, a blower fan 302 is fixed in the experiment box 102 between the mobile motor 206 and the connecting frame 427, and the upward end of the receiving hopper 301 has a feeding port that can cover the feeding port 308, and the upper edge of the feeding port 307 is There is a crushed grain conveying gap 429 between the discharge port 419 and the lower side, and the blowing port of the blower fan 302 is arranged relative t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com