Tower-type PCB and stitching method thereof

A PCB board and tower type technology, applied in the field of tower type PCB boards and their stitching, can solve the problems of failure to improve the pass rate, inconvenient welding operation of tower type circuit boards, high production costs, etc., and achieve small mechanical damage , The solder paste is evenly distributed and the deformation is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

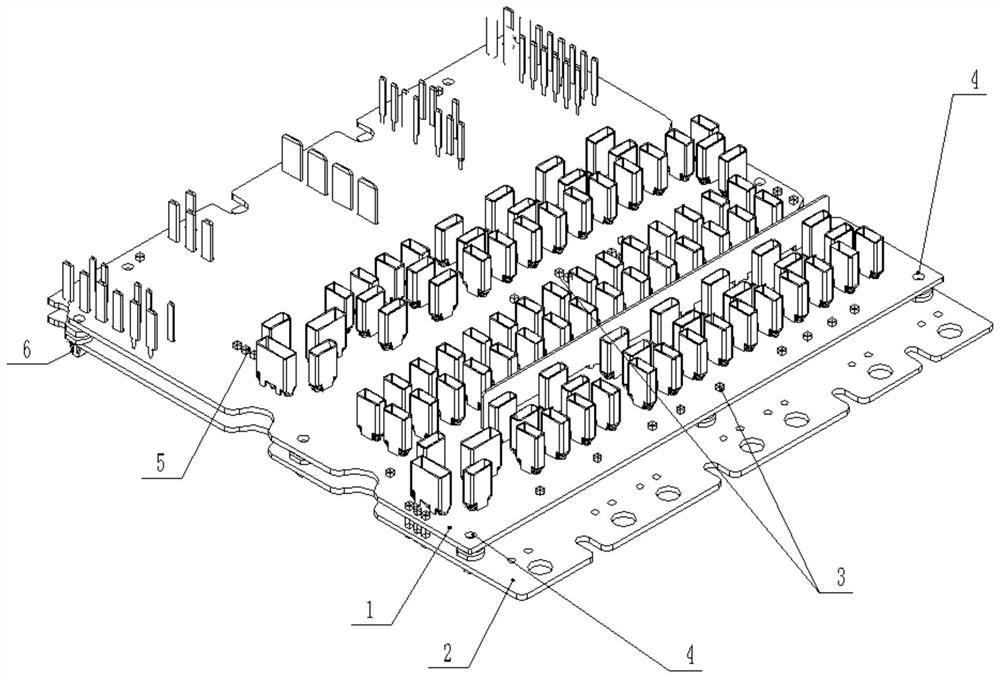

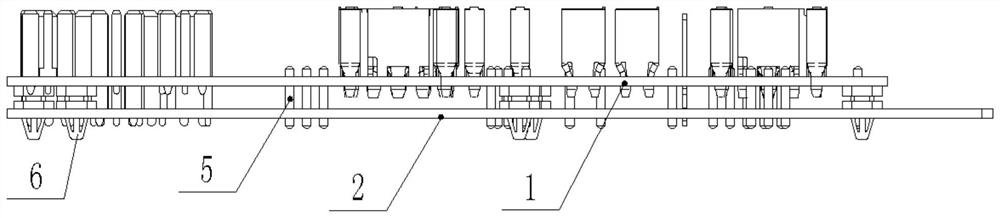

[0045] This embodiment provides a tower PCB board, such as Figure 1-Figure 3 As shown, it includes the PCB board body, the PCB board body includes the upper board 1 and the lower board 2, and also includes the guideline 5;

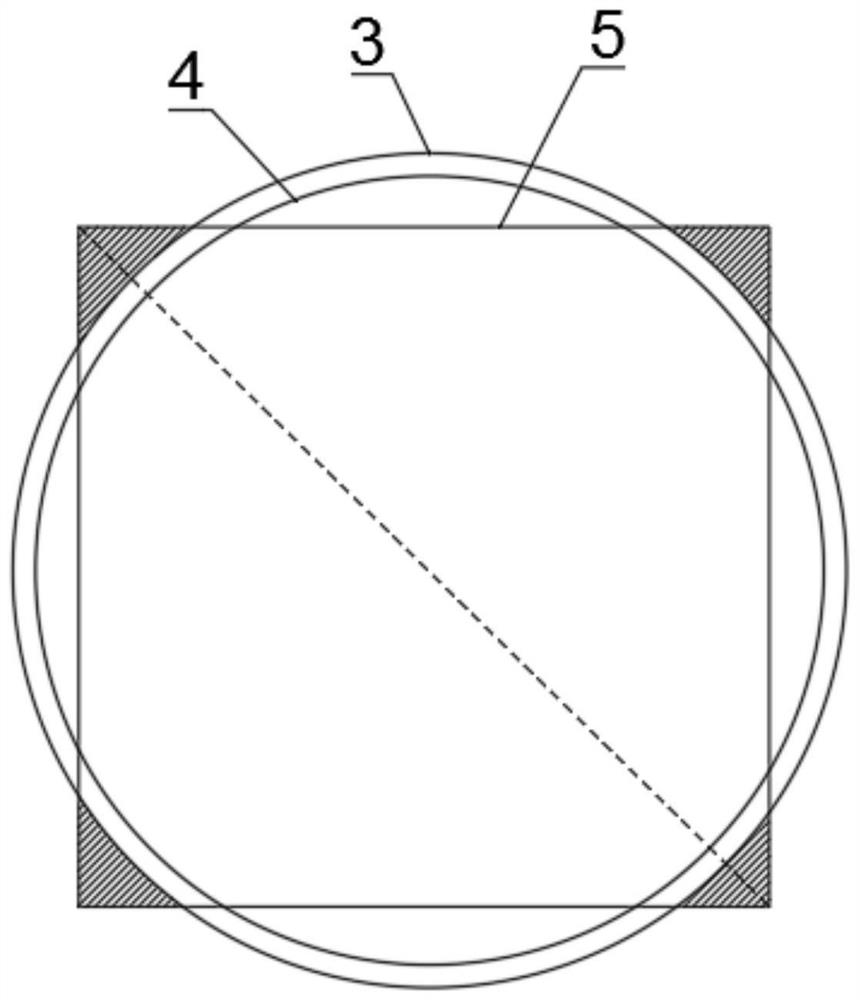

[0046] The PCB board body is provided with a plurality of welding stitching holes 3 and fixing stitching holes 4, and the guideline 5 can be inserted into the welding stitching holes 3 and the fixing stitching holes 4 and stitched for fixing the upper board 1 and the lower board 2. The welding suture hole and the fixed suture hole are all matched with the guideline gap, and the cross-sectional diagonal length of the guideline is greater than the aperture of the welded suture hole and the fixed suture hole, and the aperture of the fixed suture hole is smaller than that of the welded suture hole aperture.

[0047] Compared with the existing technology, the soldering operation of the tower circuit board is inconvenient, the production cost remains high, and t...

Embodiment 2

[0053] This embodiment is further optimized on the basis of Embodiment 1, and a method for sewing tower PCB boards is provided, including the following steps:

[0054] Step 1: evenly distribute the solder paste on the pads on the upper surface of the upper board 1 and the lower board 2;

[0055] The second step: overlap the upper plate 1 and the lower plate 2 towers;

[0056] Step 3: After overlapping, insert guideline 5 into fixed suture hole 4 for suture;

[0057] Step 4: Then insert guideline 5 into welding suture hole 3 to suture;

[0058] Step 5: Use reflow soldering to solder the PCB board body to complete the fixing of the PCB board body.

[0059] In this embodiment, the fronts of the upper board 1 and the lower board 2 are printed with solder paste, and the solder paste is evenly distributed on the welding pads of the welding seam holes 3 and the fixed seam holes 4; At the suture position, the solder paste can be evenly distributed.

[0060] In this embodiment, the...

Embodiment 3

[0065] This embodiment is further optimized on the basis of embodiment 2, and a specific implementation manner is provided.

[0066] Process before sewing:

[0067] Firstly, it is printed by a printing machine, and the solder paste is evenly distributed on the pads of the front stitching holes of the PCB board. The thickness of the solder paste is 0.5mm; the PCB board plug-in and patch are completed, and the overlapping combination of the upper and lower PCB boards is completed and fixed. , to be sutured later.

[0068] Stitching process:

[0069] The first step: First, stack the PCB boards and keep the overlapping position of the tower PCB boards fixed. This is a prerequisite for ensuring the effective stitching of the tower PCB boards in addition to the requirements for the size and accuracy of the PCB boards.

[0070] Step 2: Inserting the suture needle, manual or sewing machine insertion needle 5, should follow the following:

[0071] Material: 1.5*1.5mm guideline 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com