In-tower one-well multi-tower water distribution type high-position water collection mechanical draft cooling tower

A ventilation cooling and water collection technology, which is applied in the field of cooling towers, can solve the problems of large footprint, unsightly appearance, uneven water distribution, etc., and achieve the effects of energy saving investment, cost saving, and improvement of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

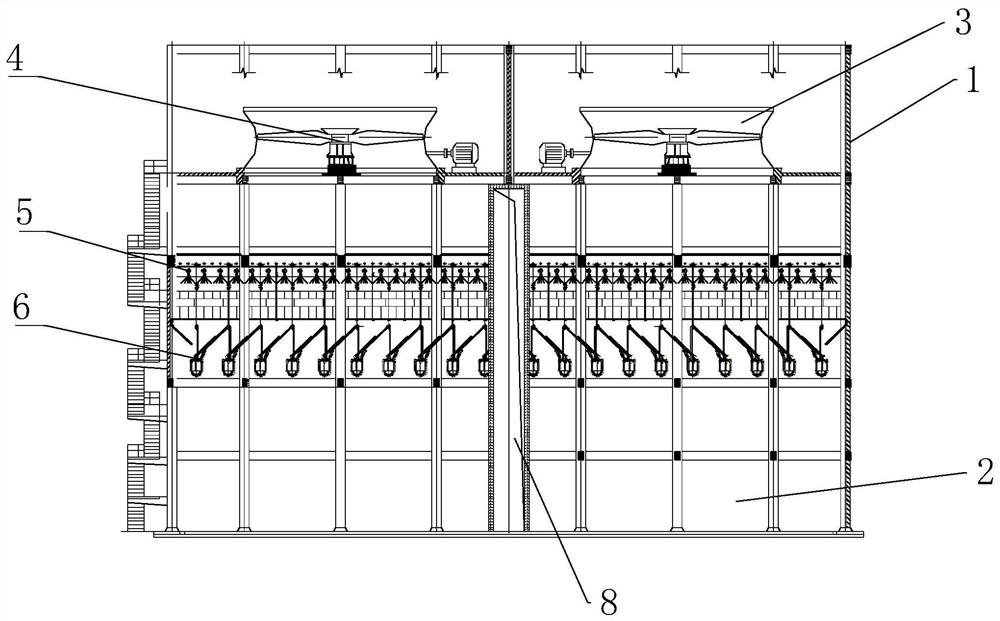

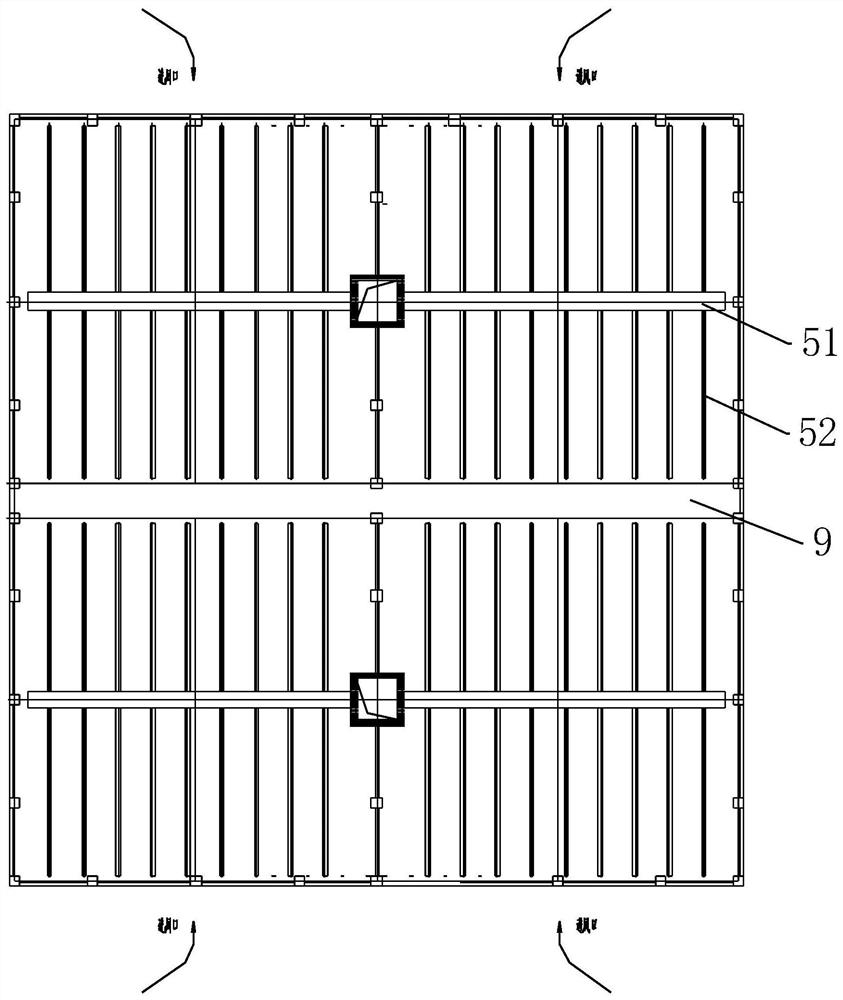

[0022] See figure 1 with figure 2 , the present invention has a tower body 1, an air inlet 2, a top air outlet 3, a top exhaust device 4, a water distribution system 5, and a high-level water collection device 6; the lower section of the tower body 1 side wall is provided with an air inlet 2, and the top is provided with a top row The tuyere 3 and the top air outlet 3 are provided with a top exhaust device 4, and the tower body 1 below the top air outlet 3 is provided with a water distribution system 5 and a high-level water collection device 6 sequentially from top to bottom. The tower body 1 is also vertically provided with an upper tower shaft 8 or a pipeline, and the upper tower shaft 8 or pipeline communicates with the water distribution system 5 . The water distribution system 5 includes a water distribution main pipe 51 and a water distribution branch pipe 52; the water distribution main pipe 51 is arranged on the upper part of the upper tower shaft 8 or the pipeline,...

Embodiment 2

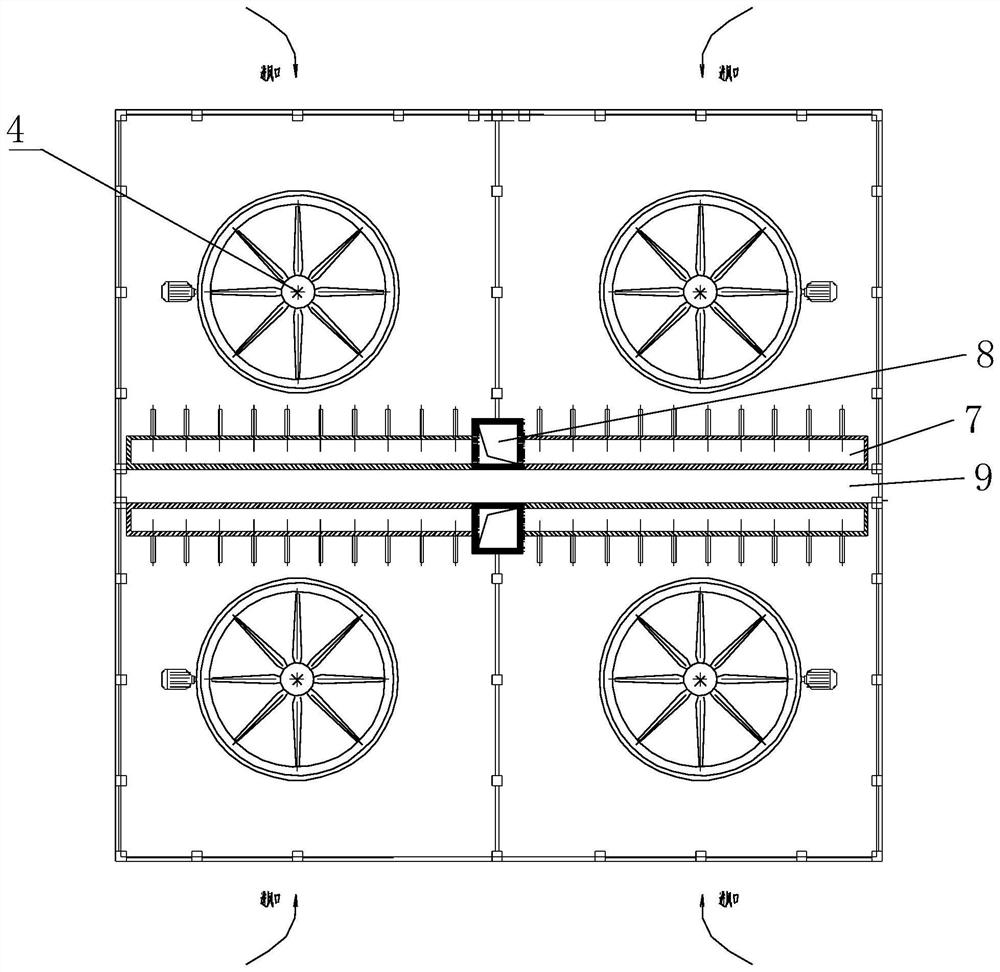

[0025] See image 3 , this embodiment is basically the same as Embodiment 1, and its distinguishing feature is that: two sides of the tower wall of the tower body 1 connected by two adjacent cooling towers are respectively provided with a horizontal water distribution tank 7, and the two water distribution tanks 7 and The upper tower shaft 8 vertically arranged on the tower wall is connected with the pipeline, and the water distribution tank 7 is connected with the water distribution system 5 . An intermediate high-level water collection tank 9 is horizontally arranged between two adjacent tower bodies 1, and the middle high-level water collection tank 9 communicates with the high-level water collection device 6, and the water distribution tank 7 is a closed structure as a whole. There are multiple cooling towers, which are installed back to back on the ground. The middle high-level water collection tank 9 is set in the tower wall opposite to the air inlet 2. The water distrib...

Embodiment 3

[0028] See Figure 4 , this embodiment is basically the same as Embodiment 2, and its distinguishing feature is that: there are multiple cooling towers arranged back to back on the ground; Or the pipeline is set between every two cooling towers, the water distribution tank 7 intersects with the middle high-level water collection tank 9, and the upper tower shaft 8 or pipeline is arranged below the water distribution tank 7, and communicates with the water distribution tank 7 central positions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com