Drum Dryer for Drying Lithium Chloride Surface Water

A drum dryer and drum drying technology, applied in non-progressive dryers, dryers, and dry goods handling, etc., can solve problems such as affecting the personal safety of workers, lithium chloride sticking to the inner wall of the drum, and cumbersome handling. achieve the effect of avoiding flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

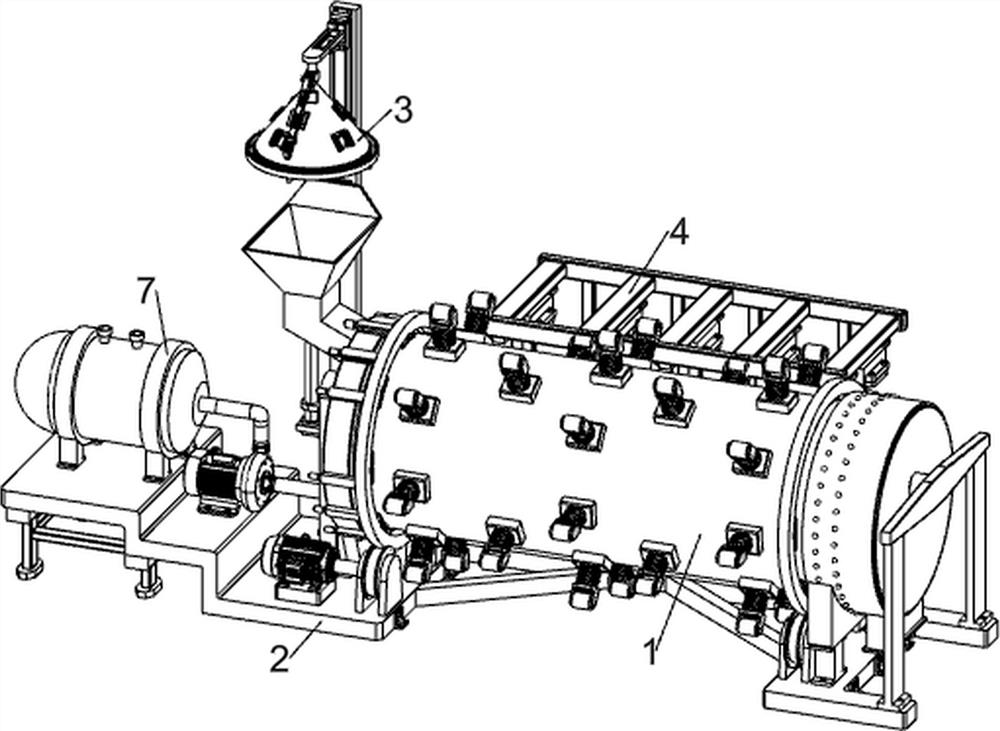

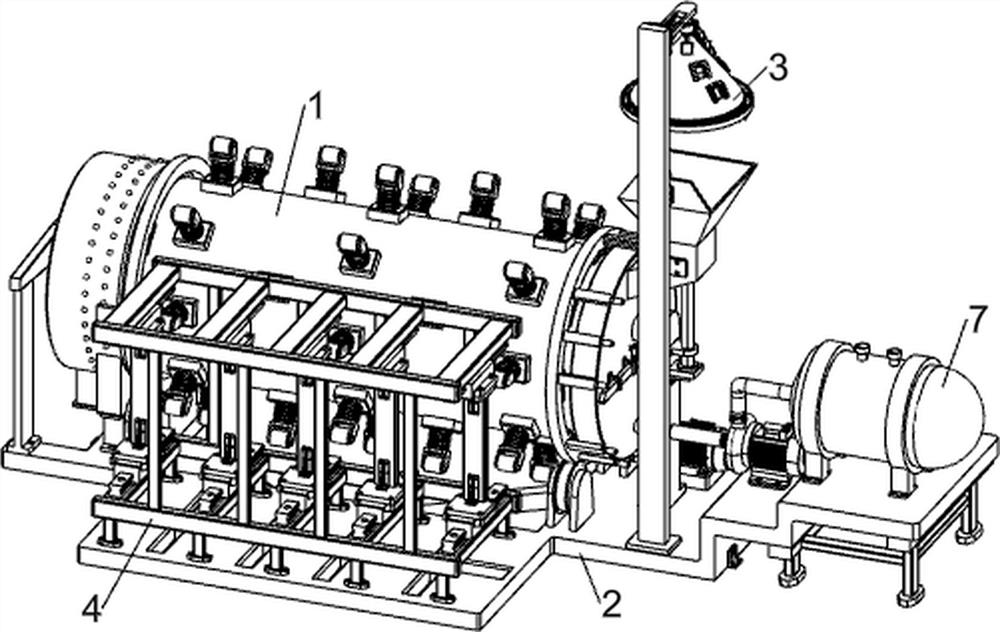

[0037] according to Figure 1-2 As shown, a drum dryer for drying lithium chloride surface water includes a drum drying system 1, a fixed machine bottom plate 2, an anti-dust feeding system 3, an anti-sticking wall control system 4 and a heating mechanism 7; a fixed machine bottom plate 2 The drum drying system 1 is installed on the right side of the top; the anti-dust feeding system 3 is installed on the top left rear side of the bottom plate of the stationary machine 2; the anti-sticking wall control system 4 is installed on the right rear side of the bottom plate 2 of the stationary machine; The rear side of the drum drying system 1; the left side of the bottom plate 2 of the stationary machine is installed with a heating mechanism 7; the right side of the heating mechanism 7 is connected to the drum drying system 1.

[0038] When in use, first transfer the lithium chloride obtained from production and processing to the bottom of the anti-dust feeding system 3 through the h...

Embodiment 2

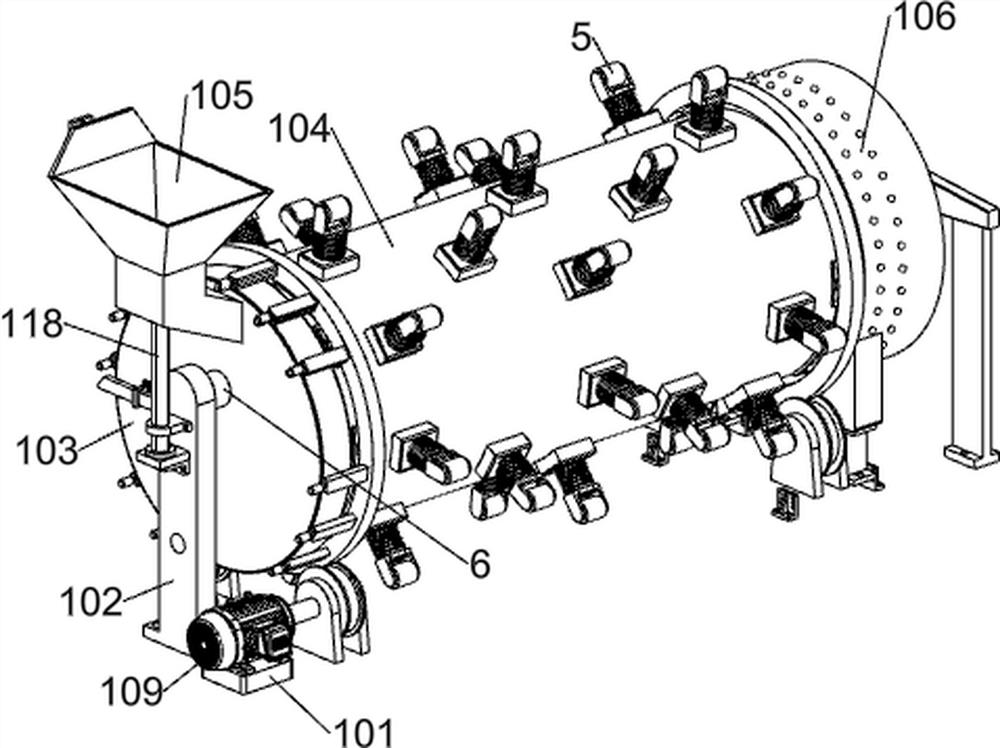

[0040] On the basis of Example 1, according to Figure 3-6 and figure 1 As shown, the drum drying system 1 includes an anti-sticking wall assembly 5, a scraping wall assembly 6, a first machine bottom plate 101, a connecting vertical plate 102, a first fixed sealing plate 103, a drying drum 104, a lower hopper 105, and a second fixed sealing plate. Disk 106, discharge cylinder 107, fixed gantry frame 108, drive motor 109, first bearing seat 110, first contact friction transmission wheel 111, support base 112, second bearing seat 113, second contact friction transmission wheel 114, the first A friction transmission ring 115, a second friction transmission ring 116, a lifting plate 117, a fixed vertical column 118 and a toggle control column 119; the top bolts of the fixed machine bottom plate 2 are connected with the first machine bottom plate 101; The driving motor 109 is connected; the bolt on the top of the base plate 2 of the fixed machine is connected with the connecting ...

Embodiment 3

[0043] On the basis of embodiment 2, according to Figure 7-9 and figure 1 As shown, the anti-flying dust feeding system 3 includes an installation vertical column 301, a first electric slide rail 302, an installation long plate 303, an installation center column 304, a conical cover 305, a collection tank ring 306, a liquid outlet pipe 307, a first guide Flow cover 308, first signal transmitter 309, second flow guide cover 310, second signal transmitter 311, third signal transmitter 312, electric rotating assembly 313, installation slant bar 314, water spray pipe 315 and signal receiver 316; the top left rear side of the bottom plate of the stationary machine 2 is fixedly connected with an installation vertical column 301; the upper side of the front part of the installation vertical column 301 is installed with a first electric slide rail 302; the upper front side of the first electric slide rail 302 is slidably connected with an installation long plate 303; the front side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com