Steam feed pump state monitoring system based on data mining

A condition monitoring system, a technology for steam-driven feed water pumps, applied in pump testing, machine/engine, biological neural network models, etc., can solve problems such as mining valuable information, and achieve the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

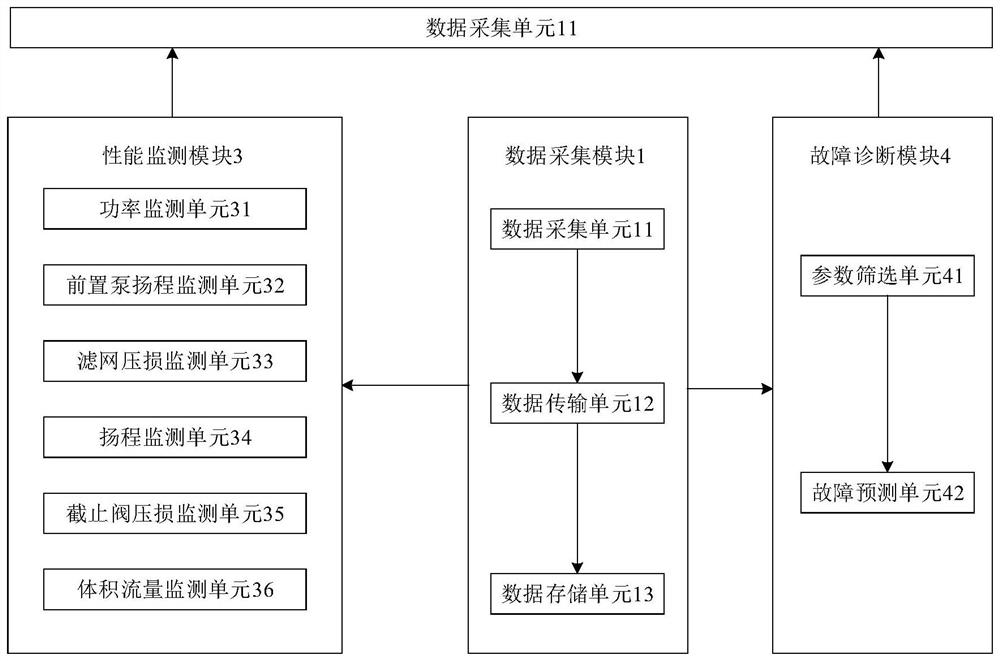

[0044] A data mining-based state monitoring system for steam-driven feedwater pumps, such as figure 1, including a data acquisition module 1, a performance monitoring module 3, a fault diagnosis module 4 and an interface display module 2;

[0045] The data acquisition module 1 includes a data acquisition unit 11, a data transmission unit 12 and a data storage unit 13. The data acquisition unit 11 collects the operation data set of the number of steam-driven feed water pumps, and stores the operation data set to the data storage unit through the data transmission unit 12. 13. The operation data set includes the inlet and outlet pressure of the steam-driven feedwater pump, the inlet and outlet temperature of the steam pump, the outlet flow rate of the front pump of the steam pump, the differential pressure of the inlet filter of the steam pump, the speed of the steam turbine of the feedwater pump, the pressure of the deaerator and the deaerator pressure of the reheater. amount o...

Embodiment 2

[0111] In this embodiment, the formula for calculating the head of the front pump is:

[0112]

[0113] Among them, H qz is the head of the front pump, p qz,in is the inlet pressure of the front pump, p qz,out is the outlet pressure of the front pump, ρ qz is the average density of the medium in the front pump, g is the earth's gravitational acceleration;

[0114] Others are the same as in Example 1.

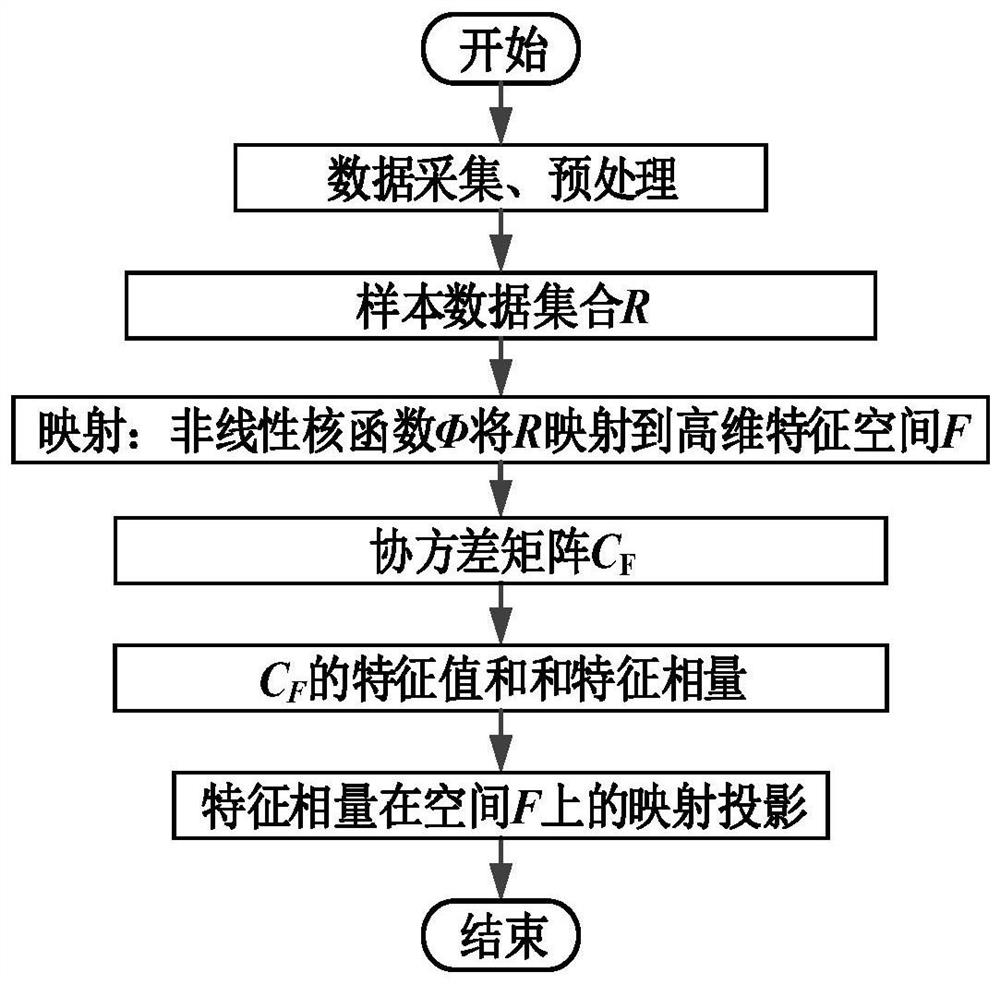

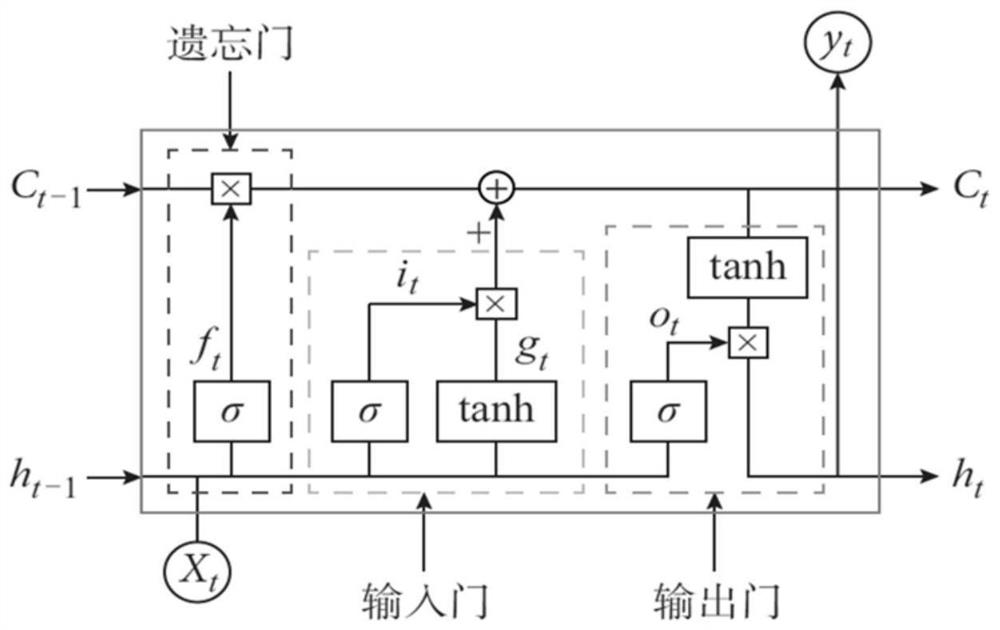

[0115] Embodiments 1 and 2 propose a data mining-based state monitoring system for steam-driven feedwater pumps. The system is based on the LSTM prediction model and supplemented by the KPCA algorithm, which solves the problem of gradients in the fault prediction model during long-sequence training The problem of explosion and gradient disappearance makes up for the problems in the planned maintenance of steam-driven feed water pumps, such as lack of pertinence, unclear primary and secondary, and rigid maintenance methods, and meets the needs of real-time status monitorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com