A kind of method of synthesizing indenoid compound

A technology of compounds and acids, which is applied in the field of synthesizing indenes, can solve the problems of easy occurrence of danger, harsh reaction conditions, and harmful by-products, and achieve the effects of wide applicability, mild reaction system, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

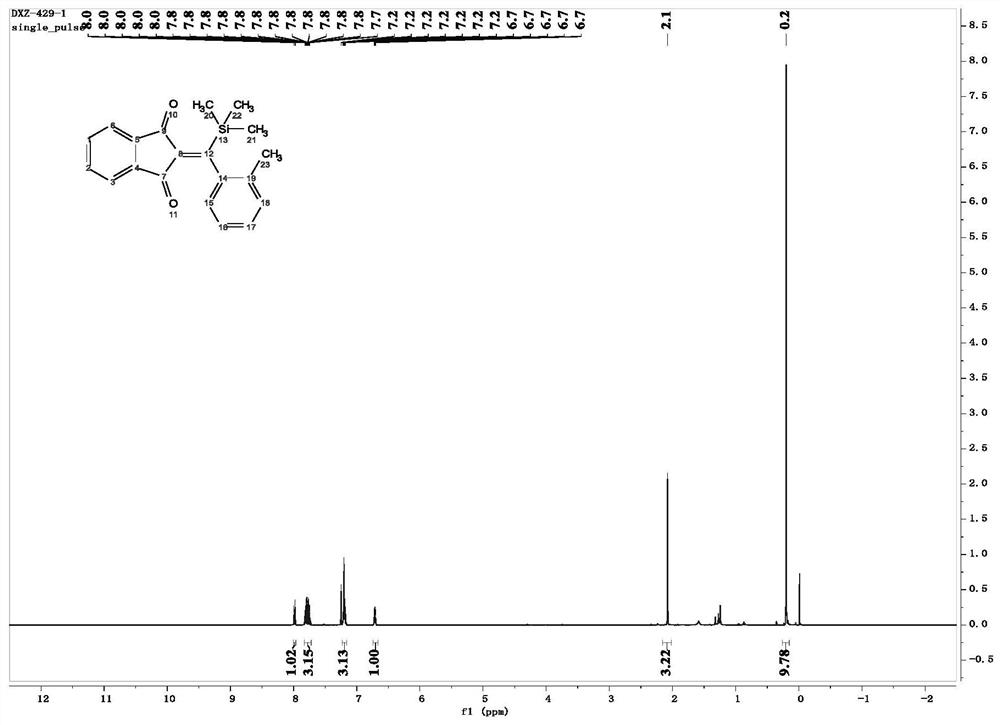

[0050] The present embodiment performs the preparation of 2- (o- tolyl (trimethylsilyl) methylene) -1H-indene-1,3(2H)-dione. The specific operation is as follows:

[0051]

[0052] In nitrogen, 2-(3-Methylsilyl)propionyl)benzylnitrile (0.1 mmol), 2-methylphenylboronic acid (0.25 mmol), [RhOH(COD)] 2 ] 2 (2.5mmol%), 1,4-dioxane (2ml) and water (0.05ml) are added to the magnet-filled Shrek tube. React at 60 °C, monitor the reaction using TLC plates, wait until 2-(3-methylsilyl)propionyl)benzyl)benzyl nitrile react completely, stop heating and cool the reaction to room temperature. The resulting mixture was filtered through a sand core funnel, washed with dichloromethane (10 ml, 3-5 times), and then the solvent was evaporated with a rotary evaporator at low pressure to give a crude product. The crude product was purified by silica gel column chromatography to obtain the desired product, 2-(o-tolyl(trimethylsilyl)methylene)-1H-indene-1, 3(2H)-dione, the product was a yellow oily liq...

Embodiment 2

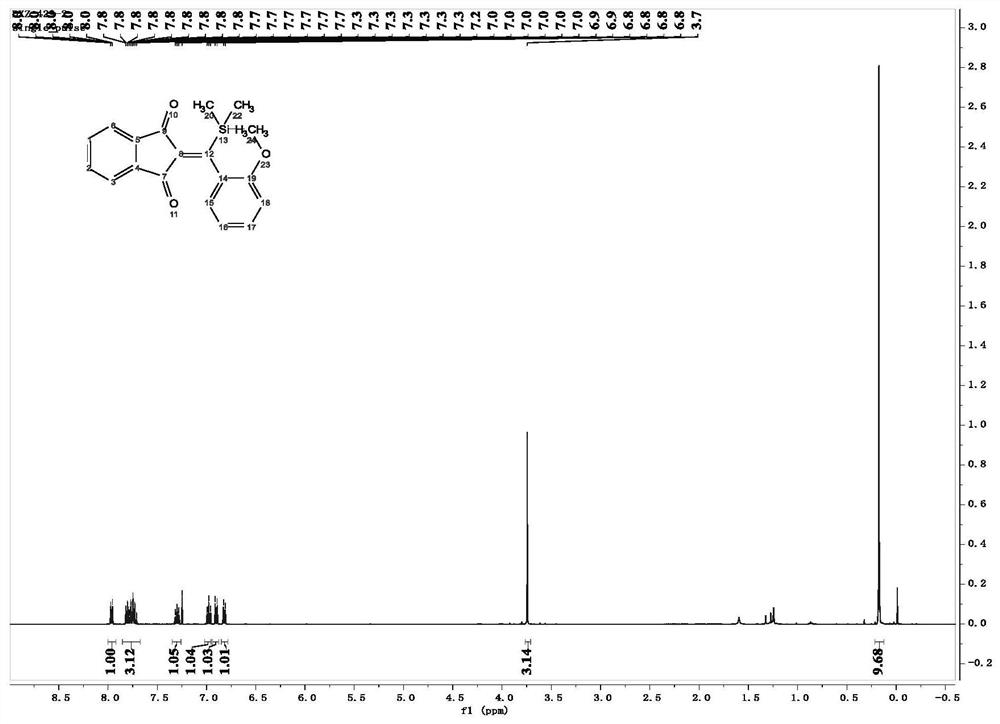

[0058] The present embodiment performs the preparation of 2- ((2-methoxyphenyl) (trimethylsilyl) methylene) -1H-indene-1,3(2H)-dione. The specific operation is as follows:

[0059]

[0060] Under nitrogen, 2-(3-Methylsilyl)propionyl)benzylnitrile (0.1 mmol), 2-methoxyphenylboronic acid (0.25 mmol), [RhOH(COD)] 2 ] 2 (2.5mmol%), 1,4-dioxane (2ml) and water (0.05ml) are added to the magnet-filled Shrek tube. React at 60 °C, monitor the reaction using TLC plates, wait until 2-(3-methylsilyl)propionyl)benzyl)benzyl nitrile react completely, stop heating and cool the reaction to room temperature. The resulting mixture was filtered through a sand core funnel, washed with dichloromethane (10 ml, 3-5 times), and then the solvent was evaporated with a rotary evaporator at low pressure to give a crude product. The crude product was purified by silica gel column chromatography to obtain the desired product, 2-(((2-methoxyphenyl) (trimethylsilyl) methylene)-1H-indene-1, 3(2H)-dione, the pro...

Embodiment 3

[0066] The present embodiment performs the preparation of 2- (naphthalen-1-yl (trimethylsilyl) methylene) -1H-indene-1, 3(2H)-dione. The specific operation is as follows:

[0067]

[0068] In a nitrogen environment, 2-(3-Methylsilyl)propionyl)benzylnitrile (0.1 mmol), naphthoronic acid (0.25 mmol), [RhOH(COD)] 2 ] 2(2.5mmol%), 1,4-dioxane (2ml) and water (0.05ml) are added to the magnet-filled Shrek tube. React at 60 °C, monitor the reaction using TLC plates, wait until 2-(3-methylsilyl)propionyl)benzyl)benzyl nitrile react completely, stop heating and cool the reaction to room temperature. The resulting mixture was filtered through a sand core funnel, washed with dichloromethane (10 ml, 3-5 times), and then the solvent was evaporated with a rotary evaporator at low pressure to give a crude product. The crude product was purified by silica gel column chromatography to obtain the desired product, 2-(naphthalen-1-yl(trimethylsilyl)methylene)-1H-indene-1, 3(2H)-dione, the product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com