High-performance ternary precursor and preparation method thereof

A precursor, high-performance technology, applied in the direction of chemical instruments and methods, electrical components, active material electrodes, etc., to achieve the effect of reducing growth speed, increasing transmission speed, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

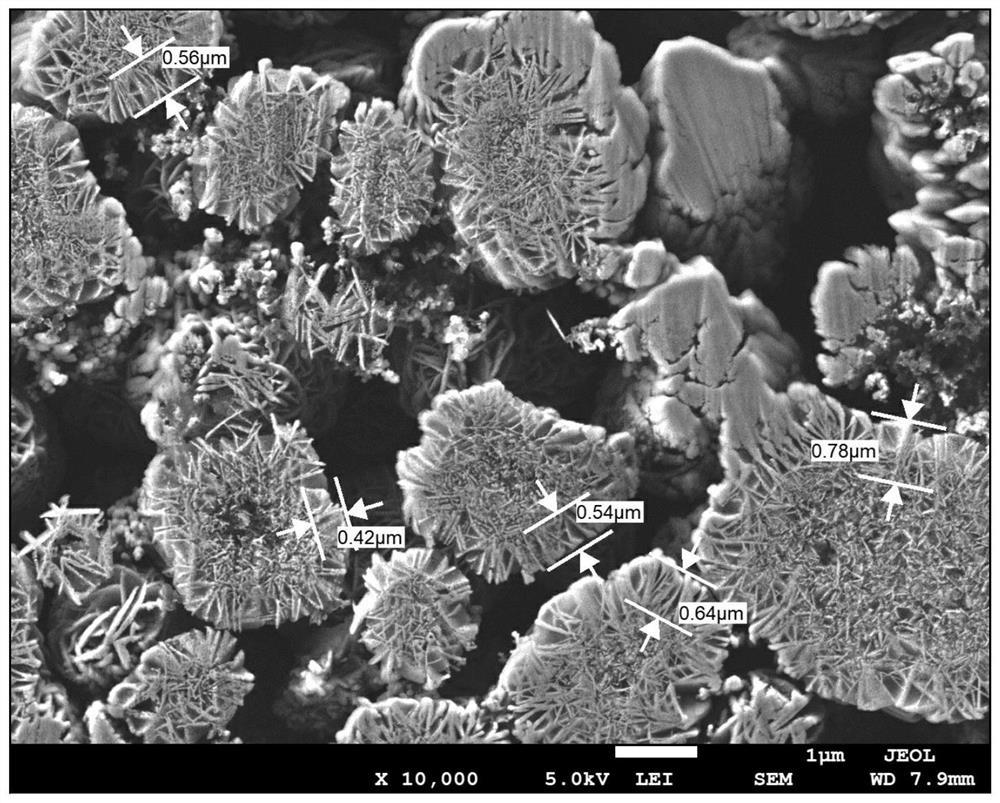

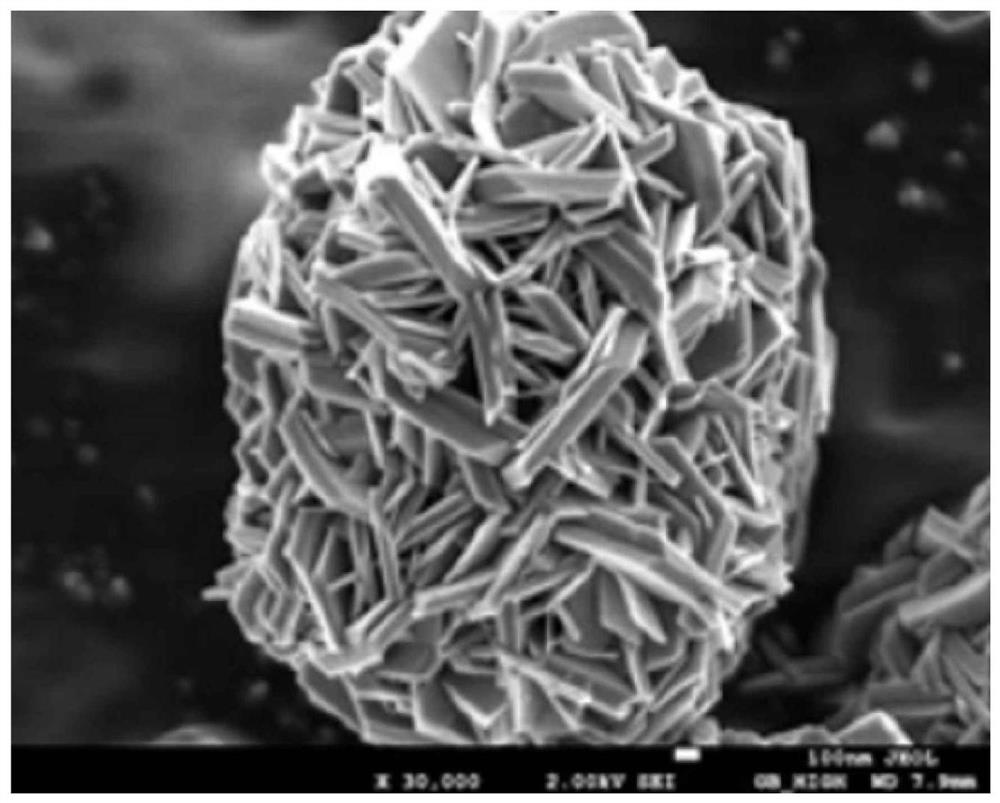

Image

Examples

Embodiment 1

[0050] Embodiment 1: a kind of preparation method of high-performance ternary precursor, comprises the following steps successively:

[0051] Step 1, prepare the first mixed solution of Ni, Co, Mn, hydrogen peroxide, ethylenediaminetetraacetic acid and lanthanum sulfate, wherein the molar ratio of Ni, Co, Mn is 50.4:20.1:29.5, the total concentration of Ni, Co, Mn 2.0 mol / L, the concentration of hydrogen peroxide is 0.15mol / L, the concentration of ethylenediaminetetraacetic acid is 0.35mol / L, and the concentration of lanthanum sulfate is 0.003mol / L; the pH of the first mixed solution is 1.5~3.5 ;

[0052] Prepare the second mixed solution of Ni, Co, Mn, EDTA and lanthanum sulfate, wherein the molar ratio of Ni, Co, Mn is 50.4:20.1:29.5, and the total concentration of Ni, Co, Mn is 2.0mol / L , the concentration of ethylenediaminetetraacetic acid is 0.65mol / L, the concentration of lanthanum sulfate is 0.003mol / L; the pH of the second mixed solution is 1.5 ~ 3.5;

[0053] Prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com