Cleansing oil containing astaxanthin liposome and preparation method thereof

A technology of liposome and astaxanthin, which is applied in the direction of cosmetic preparations, toiletry preparations, cosmetics, etc., can solve the problems of inability to clean oil stains and poor practicability, and achieve strong practicability, improve work efficiency, and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the above-mentioned cleansing oil containing astaxanthin liposomes comprises the following preparation steps:

[0042] S1, weigh the above-mentioned raw materials according to the formula quantity;

[0043] S2, the weighed cetyl ethyl hexanoate, squalane, pentaerythritol tetrakis (bis-tert-butyl hydroxyhydrogenated cinnamate) ester, polyglycerol-6 dicaprate, polyglycerol-2 caprate , liposome, and dopamine were mixed at 45-60°C to obtain phase A;

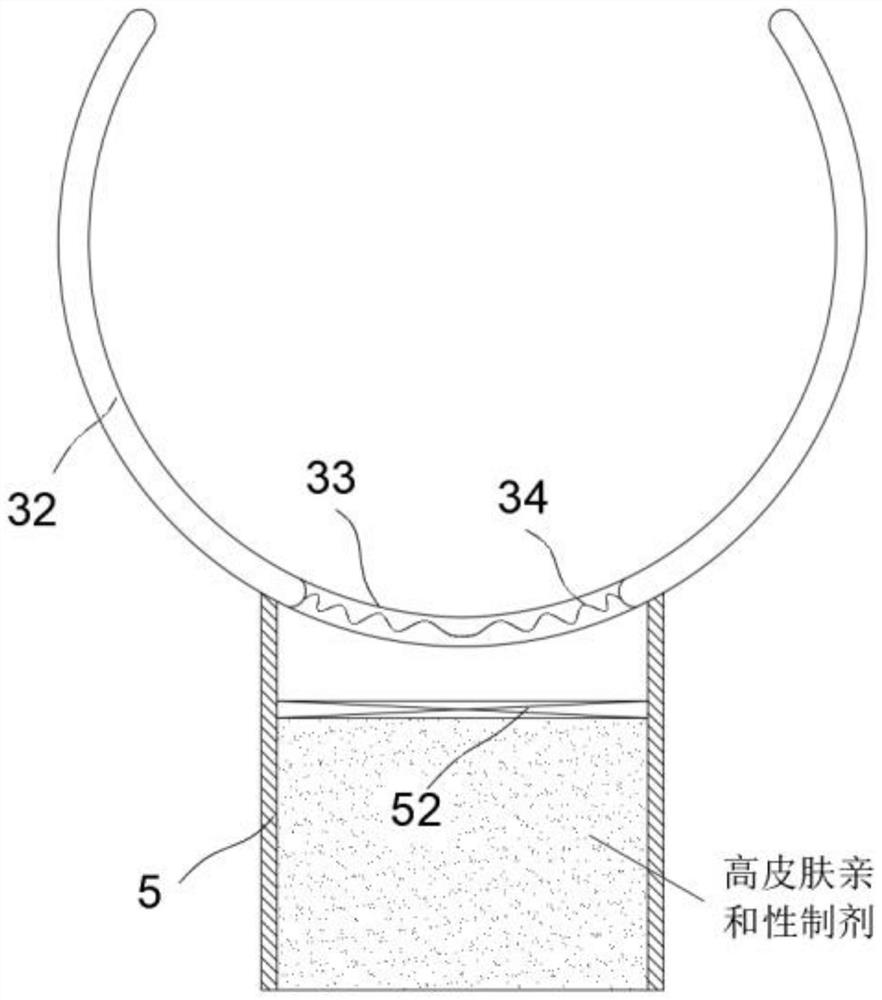

[0044] S3. Mix astaxanthin with phase A to obtain phase B, and apply the high-skin-affinity preparation on phase B to obtain a cleansing oil containing astaxanthin liposome.

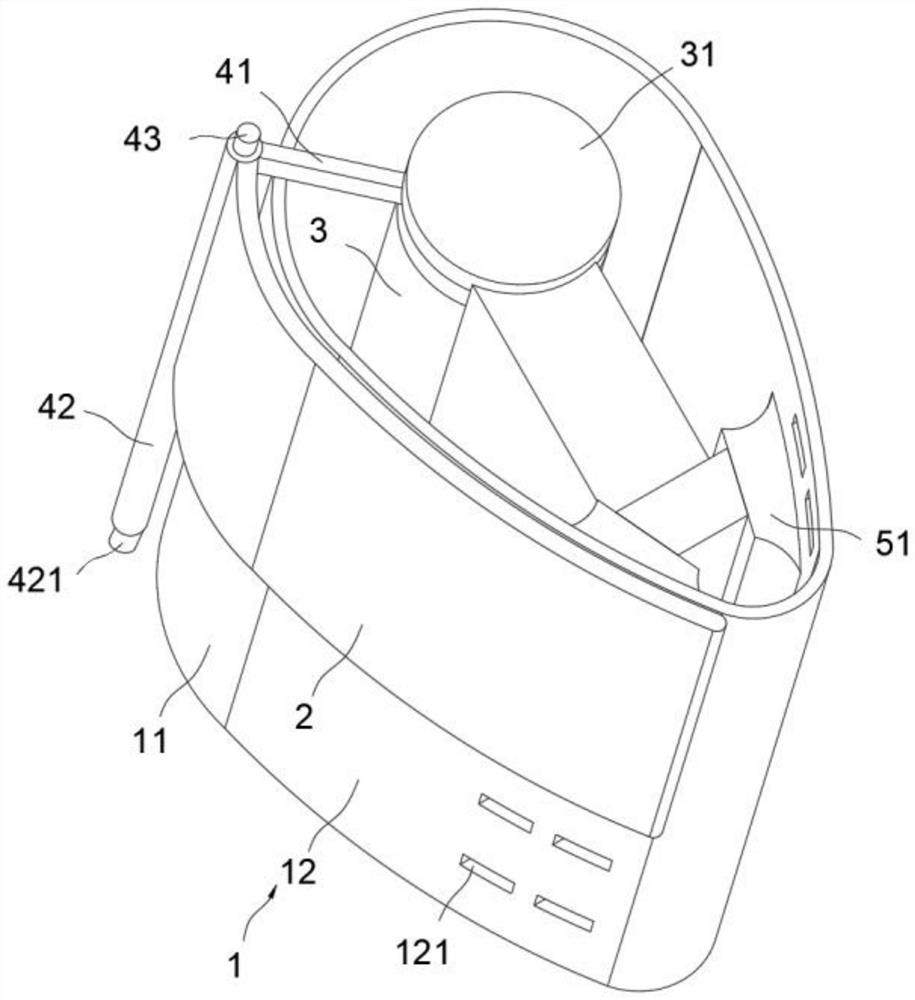

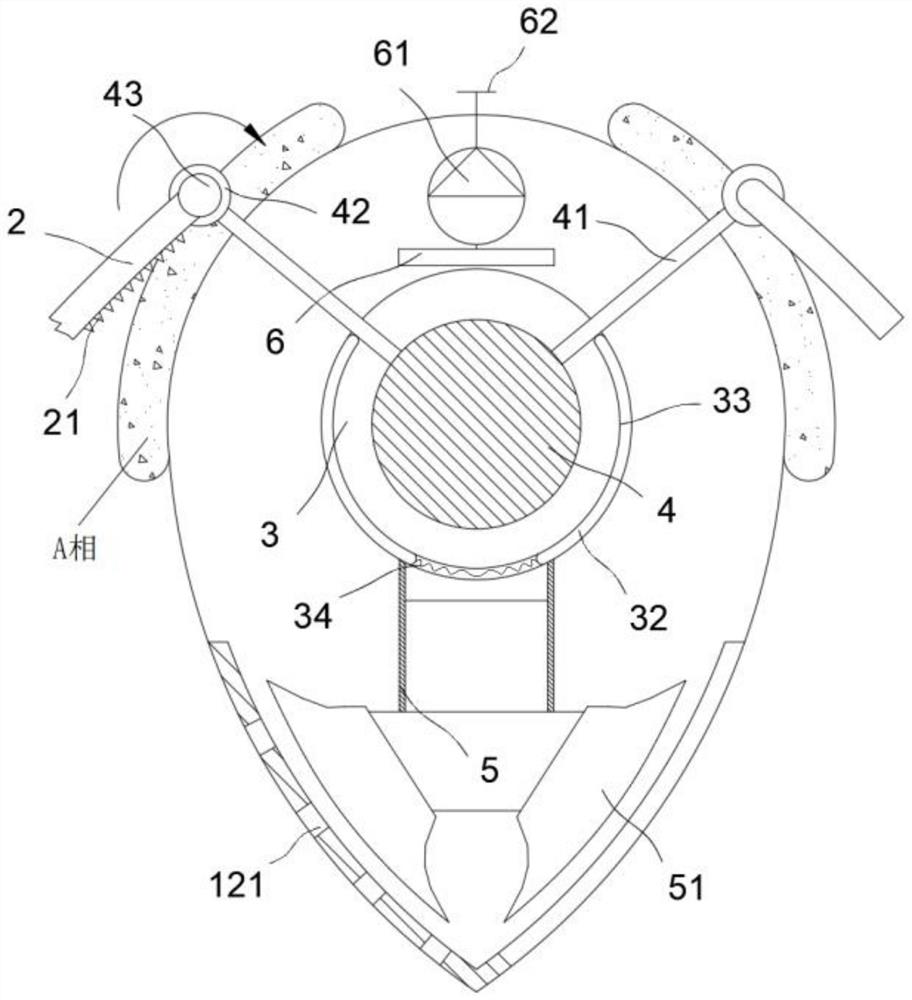

[0045] The process of step S3 adopts the following equipment: comprise processing shell (1), described processing shell (1) is made up of interconnected semicircular shell (11) and arc shell (12), the top inner wall of described semicircular shell (11) A hydraulic pump (61) is installed, and the inside of the processing shell ...

Embodiment 1

[0058] A cleansing oil containing astaxanthin liposome, comprising the following components in parts by mass: 50 parts of cetyl ethylhexanoate, 5 parts of squalane, 0.03 part of pentaerythritol tetrakis (bis-tert-butyl hydroxyhydrocinnamic acid) ester, 1.5 parts of polyglyceryl-6 dicaprate, 5.5 parts of polyglyceryl-2 caprate, 70 parts of liposome, 0.1 part of astaxanthin, 0.02 part of dopamine, 0.3 part of high skin affinity And sexual preparations.

[0059] The high skin affinity preparation is a composition of targeting functional substance and bacterial cellulose at a mass ratio of 30:1.

[0060] The targeting functional substance: mix tetrahydromethylpyrimidine carboxylic acid, water, and hexacyclite micropowder in a mass ratio of 1:8:2, heat-preserve and shake at 40°C, and heat up to 100°C to remove water.

[0061] The particle size of the hexacyclite fine powder is 100-250 μm.

Embodiment 2

[0063] A cleansing oil containing astaxanthin liposome, comprising the following components in parts by mass: 85 parts of cetyl ethylhexanoate, 35 parts of squalane, 0.1 part of pentaerythritol tetrakis (bis-tert-butyl hydroxyhydrocinnamic acid) ester, 4 parts of polyglyceryl-6 dicaprate, 8.5 parts of polyglyceryl-2 caprate, 100 parts of liposome, 1 part of astaxanthin, 0.07 part of dopamine, 2 parts of high skin affinity And sexual preparations.

[0064] The high skin affinity preparation is a composition of targeting functional substance and bacterial cellulose at a mass ratio of 50:1.

[0065] The targeting functional substance: mix tetrahydromethylpyrimidine carboxylic acid, water, and hexacyclite micropowder in a mass ratio of 1:13:5, heat and shake at 55°C, and heat up to 100°C to remove water.

[0066] The particle size of the hexacyclite fine powder is 100-250 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com