Air supply system, control method for air supply system, and control program for air supply system

A technology of air supply and air drying, applied in the direction of separation methods, chemical instruments and methods, brakes, etc., can solve the problems of reduced purification function, achieve the effect of reducing consumption and maintaining dehumidification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

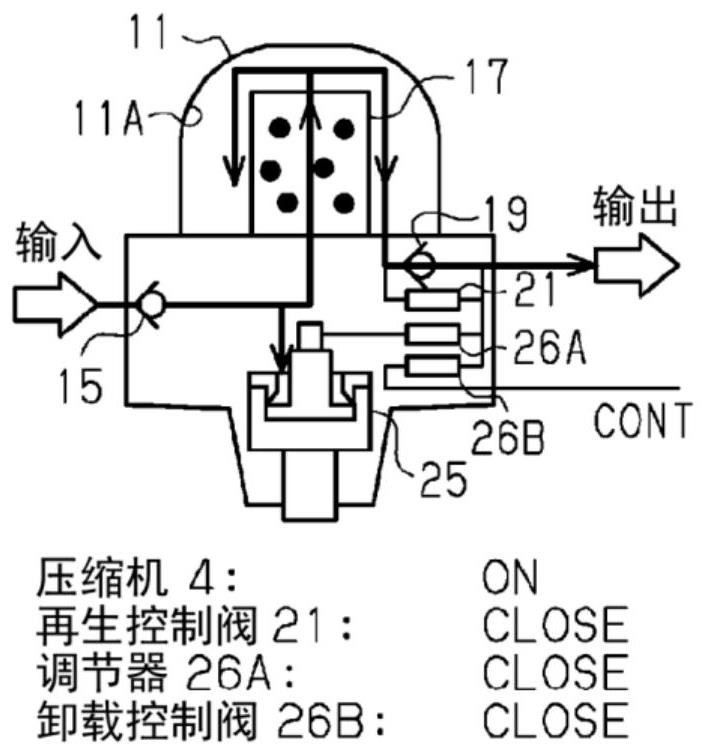

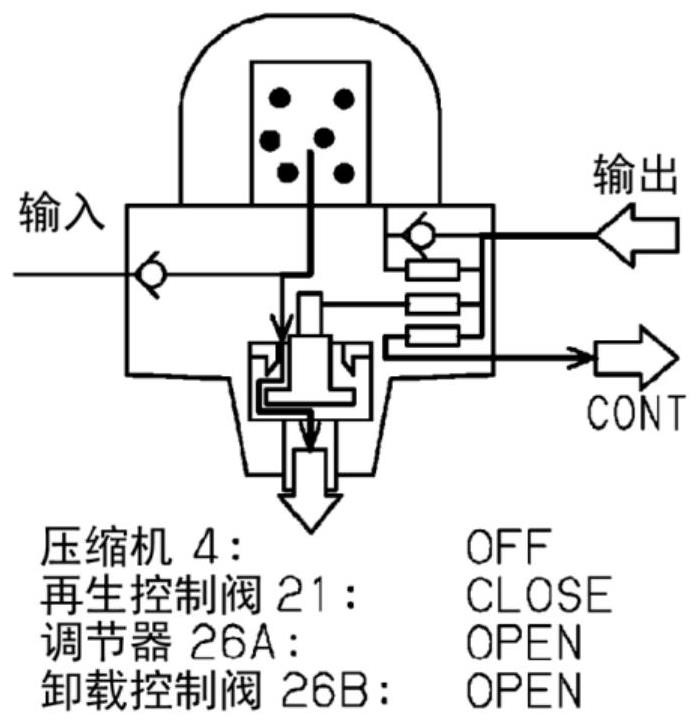

[0039] refer to Figure 1 to Figure 6 A first embodiment of the air supply system will be described. Air supply systems are installed in vehicles such as trucks, buses, and construction machinery. The compressed dry air generated by the air supply system is used, for example, in an air pressure system such as a brake system (brake device) or a suspension system (suspension device) of an automobile.

[0040]

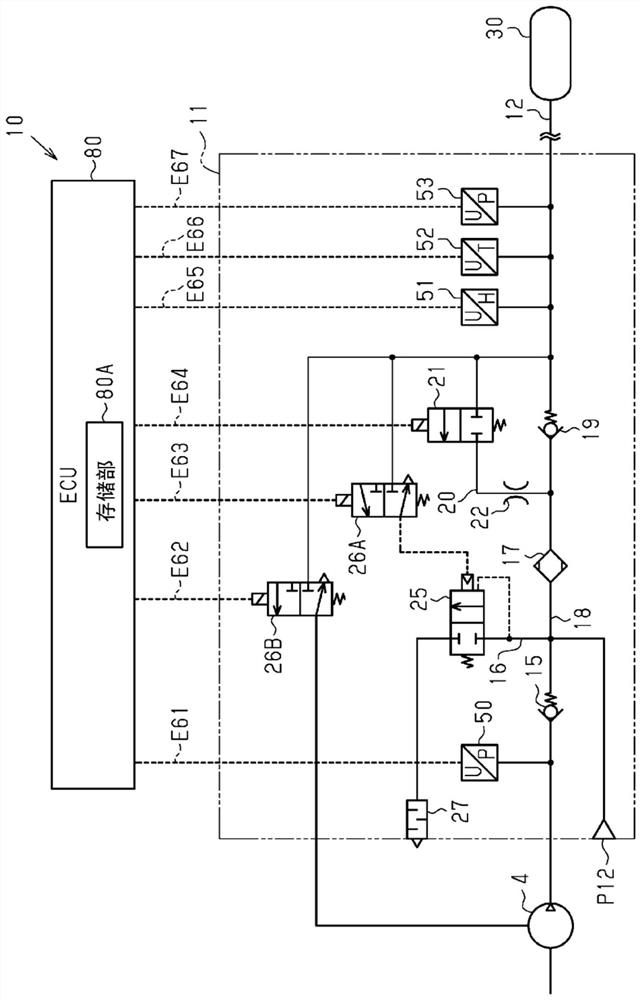

[0041] refer to figure 1 The air supply system 10 will now be described. The air supply system 10 includes a compressor 4 , an air drying circuit 11 , and an ECU (Electronic Control Unit: Electronic Control Unit) 80 . In addition, the ECU 80 functions as a control device, a dehumidification operation execution unit, a regeneration operation execution unit, and a setting unit.

[0042] The ECU 80 is connected to the air drying circuit 11 via a plurality of wires E61 to E67. The ECU 80 includes a calculation unit, a communication interface unit, a volatile storage un...

no. 2 approach

[0122] Follow Figure 8 and Figure 9 , to describe the second embodiment. The second embodiment has the same point as the first embodiment in that the standard regeneration air volume and the corrected unit air volume are changed according to the state of the air drying circuit 11 to calculate the regeneration air volume. In addition, in the first embodiment, the standard regeneration air volume and the corrected unit air volume are changed according to the cut-out pressure, but in the second embodiment, the standard regeneration air volume and the corrected unit air volume are changed according to the temperature of the compressed dry air , which is different from the first embodiment in this point. Therefore, in the following, configurations different from those of the first embodiment will be mainly described in detail, and detailed descriptions of the same configurations will be omitted for convenience of description.

[0123] Figure 8A It is a map 110 for setting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com