Textile quality detection method and system based on image identification

A technology of image recognition and textiles, applied in the field of intelligent manufacturing equipment, can solve the problems of automatic decision-making priority of customers without manufacturing enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

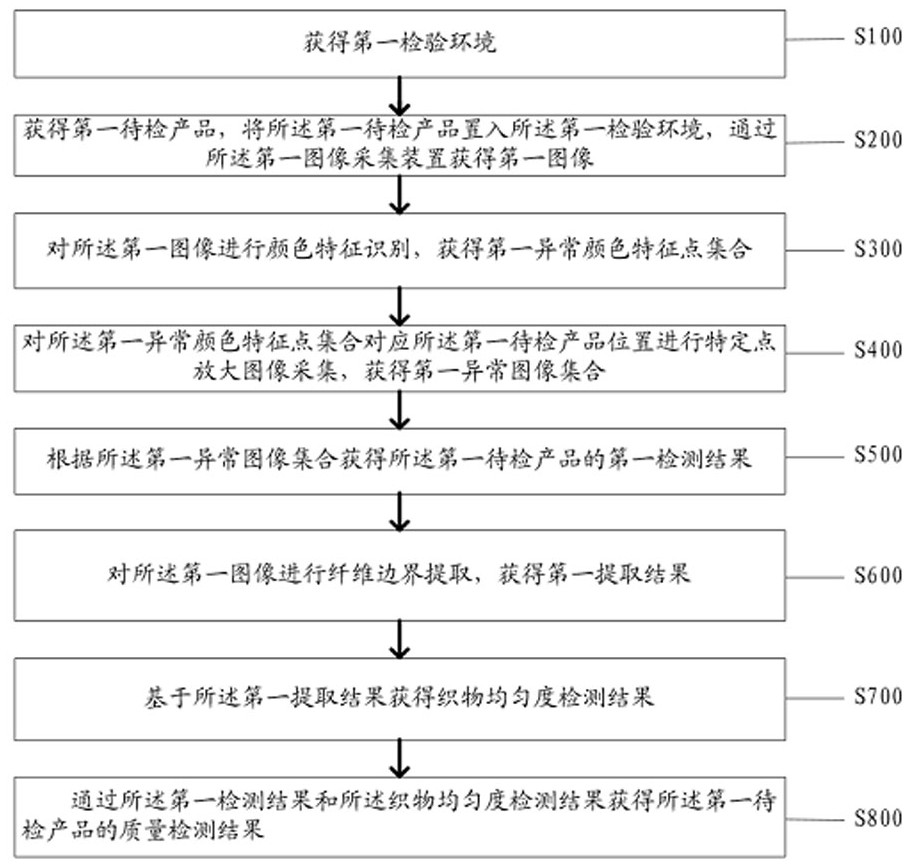

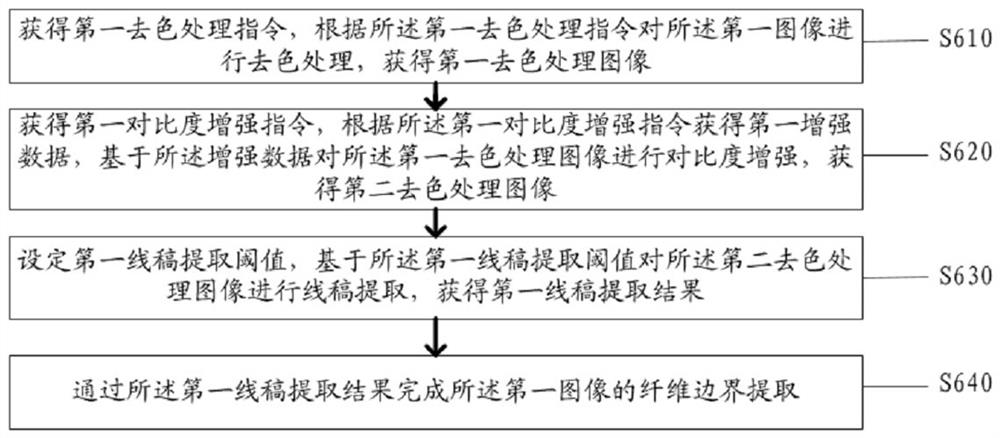

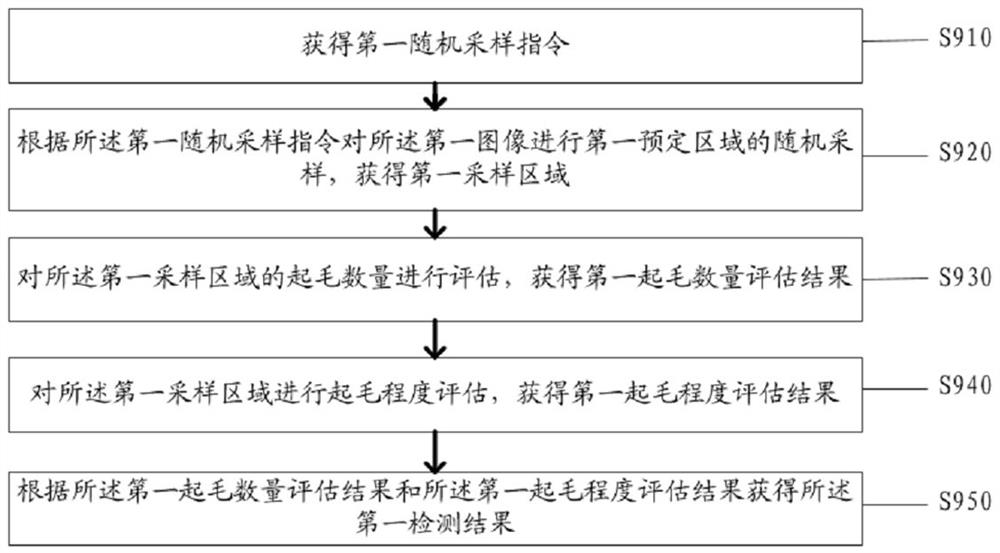

[0025] Such as figure 1 As shown, the embodiment of the present application provides a textile quality detection method based on image recognition, wherein the method is applied to a textile quality detection system, and the system is connected in communication with the first image acquisition device, and the method includes:

[0026] S100: Obtain a first inspection environment;

[0027] S200: Obtain a first product to be inspected, place the first product to be inspected in the first inspection environment, and obtain a first image through the first image acquisition device;

[0028]Specifically, the first inspection environment is a preset environment that will not affect the chemical properties and physical properties of the textiles, preferably in a cool, dry and light-proof environment; the first product to be inspected is Textiles that need to undergo quality inspection; the first image acquisition device is a device arranged in the first inspection environment to colle...

Embodiment 2

[0081] Based on the same inventive concept as an image recognition-based textile quality detection method in the foregoing embodiments, as Figure 4 As shown, the embodiment of the present application provides a textile quality inspection system based on image recognition, wherein the system includes:

[0082] A first obtaining unit 11, the first obtaining unit 11 is used to obtain a first inspection environment;

[0083] A second obtaining unit 12, the second obtaining unit 12 is used to obtain a first product to be inspected, place the first product to be inspected in the first inspection environment, and obtain a first image through a first image acquisition device;

[0084] A third obtaining unit 13, the third obtaining unit 13 is configured to perform color feature recognition on the first image, and obtain a first set of abnormal color feature points;

[0085] A fourth obtaining unit 14, the fourth obtaining unit 14 is configured to collect a specific point enlarged ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com