Flywheel bolt cap compliance detecting device and using method thereof

A detection device and bolt technology, applied in the direction of mechanical thickness measurement, etc., can solve the problem of inability to quickly detect the thickness of the bolt cap, and achieve the effects of improving detection applicability, ensuring stability and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

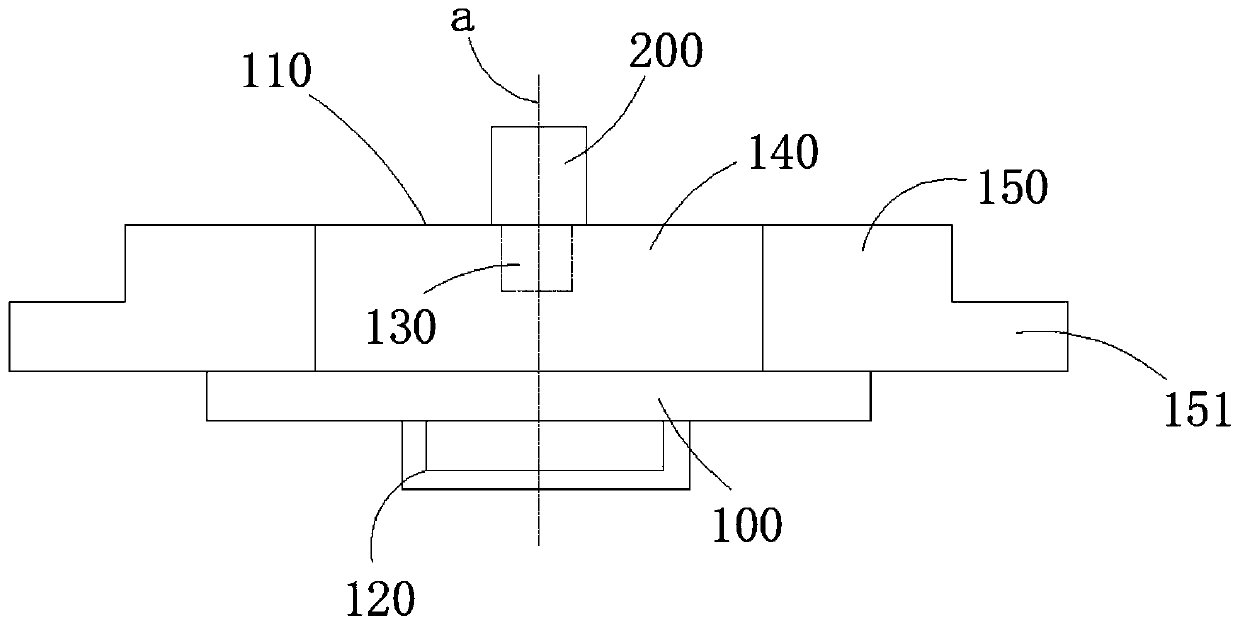

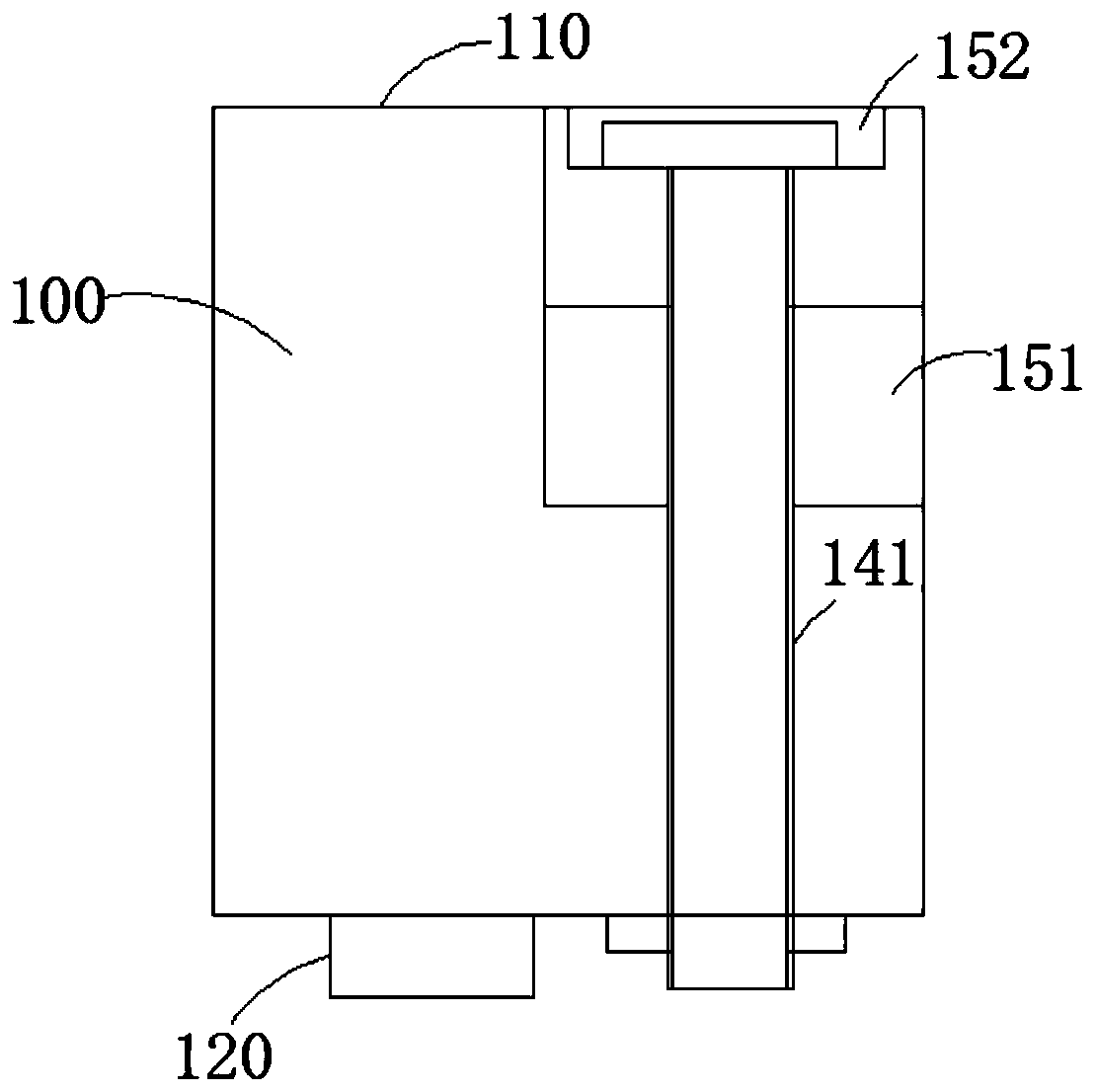

[0035] Refer to attached figure 1 and figure 2 As shown, a flywheel bolt cap compliance detection device in this embodiment includes a checker body 100, which is provided with a detection surface 110 and a hand-held part 120, and a threaded hole 130 is opened in the middle of the checker body 100. The tool body 100 is connected to the limit pin 200 through the threaded hole 130. The handle 120 and the limit pin 200 are respectively located on both sides of the test tool body 100. The axis of the limit pin 200 is perpendicular to the detection surface 110. There is a connecting end 140, and the connecting end 140 is fixedly connected to two symmetrical sliders 150. The bottom surface of the sliders 150 and the detection surface 110 are located on the same plane. Compared with standard bolts, there is not much difference in the thickness of the bolt caps, so the difference in appearance between the two is not obvious. The inspection process cannot effectively identify whether ...

Embodiment 2

[0040] Refer to attached figure 1 , figure 2 and image 3 As shown, the use method of a flywheel bolt cap compliance detection device in this embodiment is that the bottom surface of the slider 150 and the detection surface 110 rotate around the limit pin 200 to detect whether there is interference.

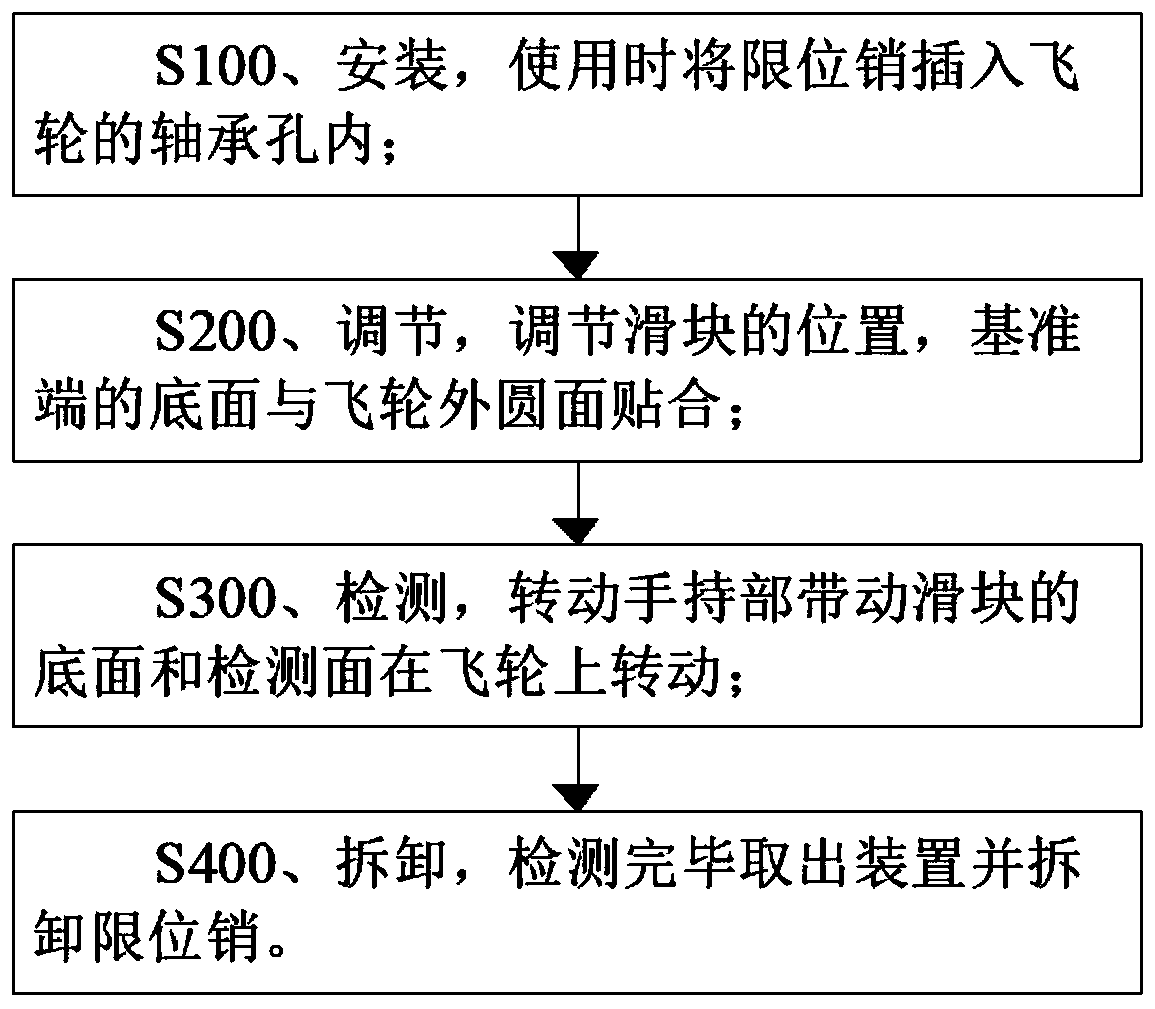

[0041] The usage method of this embodiment includes the following steps:

[0042] S100, installation, when using, insert the limit pin 200 into the bearing hole of the flywheel;

[0043] S200, adjust, adjust the position of the slide block 150, the bottom surface of the reference end 151 is attached to the outer circular surface of the flywheel;

[0044] S300, detection, rotating the handle 120 to drive the bottom surface of the slider 150 and the detection surface 110 to rotate on the flywheel;

[0045] S400, dismantling, taking out the device after the detection and disassembling the limit pin 200 .

[0046] The specific method of step S200 adjustment in this embodiment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com