Real-time intelligent high-robustness layout optimization method and system for multi-shape manufactured parts

A technology with strong robustness and optimization method, applied in manufacturing computing systems, forecasting, instruments, etc., can solve problems such as unsolvable industrial needs, difficult, complex situations, etc., and achieve saving of industrial raw materials, high real-time performance, and anti-interference strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This example considers the layout optimization of rectangular pieces to verify the feasibility of the present invention for layout optimization of rectangular pieces. Let the length and width of the raw material composite rectangular plate be 300×300, and a part of the raw material composite rectangular plate has been cut and used, such as Figure 4 As shown, at present, it is necessary to cut out a rectangular piece with a length of 50 and a width of 45 for processing and production. After calculation of the algorithm, the best layout is horizontal, and the coordinates of the upper left vertex are (52, 98), such as Figure 5 shown;

example 2

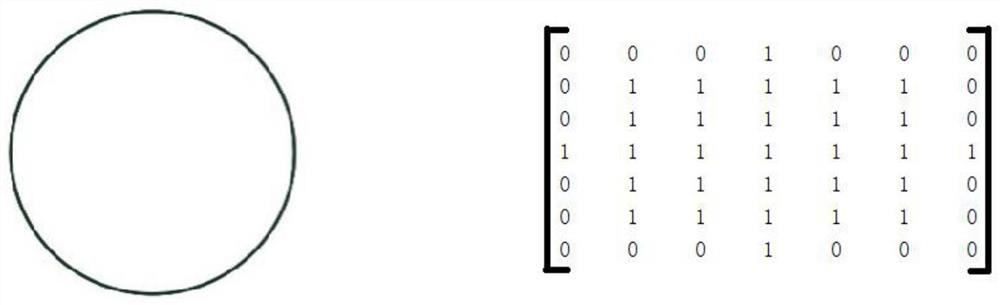

[0047] This example considers the layout optimization of circular parts to verify the feasibility of the present invention for layout optimization of circular parts. Let the length and width of the raw material composite rectangular plate be 300×300, and a part of the raw material composite rectangular plate has been cut and used, such as Image 6 As shown; now it is necessary to cut out a circular piece with a radius of 17 for processing and production. After the algorithm is calculated, the layout result obtained is as follows Figure 7 shown;

example 3

[0049] This example considers the layout optimization of circular parts to verify the feasibility of the present invention for layout optimization of circular parts. Let the length and width of the raw material composite rectangular plate be 300×300, and a part of the raw material composite rectangular plate has been cut and used, such as Figure 8 As shown; now it is necessary to cut out an equilateral right-angled triangle with a side length of 50 for processing and production. After calculating the algorithm, it is obtained that the best layout is rotated at 0°, and the coordinates of the apex of the right angle are (0, 230); Figure 9 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com