High-safety-performance-based carbon-based capacitor monorail hoist

A safety performance, monorail crane technology, applied in the field of cranes, can solve the problems of small lifting capacity of the lifting beam, complex design inside the beam, and low lifting height, so as to achieve accurate measurement data and improve the efficiency of measurement work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

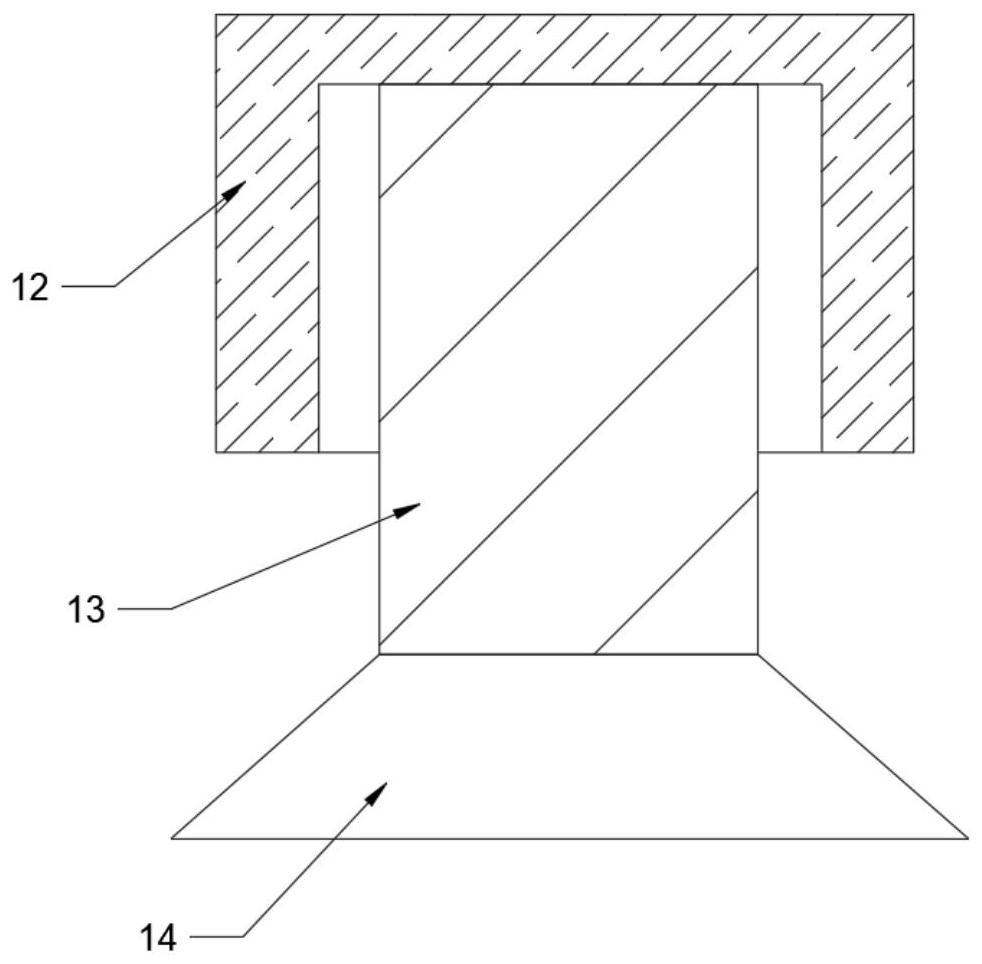

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] combined with figure 1 to attach image 3 , a carbon-based capacitor monorail crane based on high safety performance, including a base plate 1, horizontal adjustment structures are provided at the four corners of the bottom of the base plate 1, bubble levels 2 are provided on the front and side of the base plate 1, and the base plate 1 A U-shaped frame 3 is provided on the upper end surface, and a screw rod 4 is rotationally connected between the two side walls of the upper end of the U-shaped frame 3, and a runner 5 is provided at one end of the screw rod 4 passing through the side of the U-shaped frame 3. Screw rod 4 is screwed to be provided with slide block 6, and the inner top surface of described U-shaped frame 3 is provided with chute 7, and described chute 7 is matched with slide block 6, and described slide block 6 lower end is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com