System and method for recovering heat of discharged flowing calcium carbide through combination of air blowing and air inducing

A technology of flowing calcium carbide and heat, applied in furnaces, waste heat treatment, furnace components, etc., which can solve the problems of heat waste, low thermal conductivity of calcium carbide, and difficulty in recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

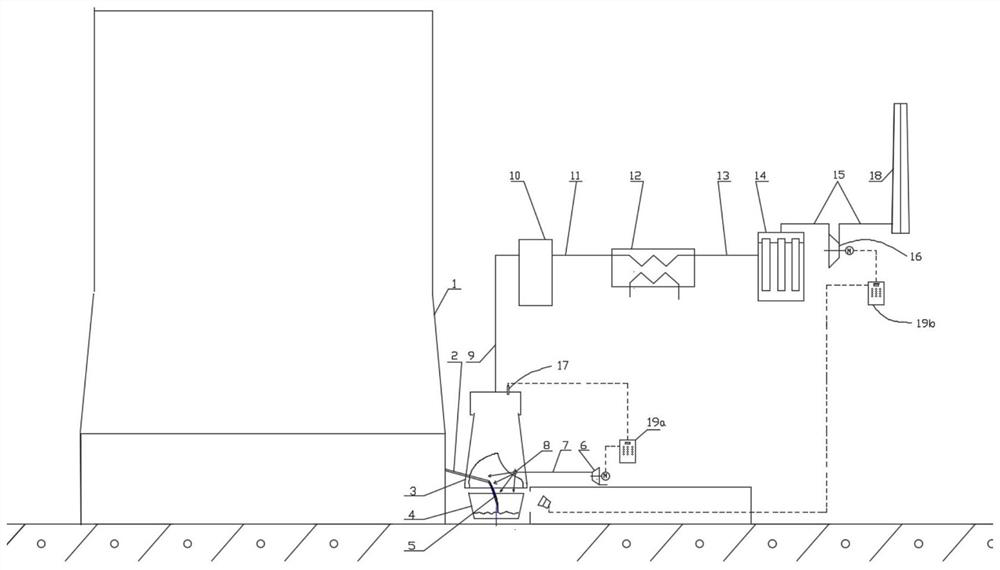

[0037] refer to figure 1 , a system for recovering the heat of flowing calcium carbide by blowing and inducing wind, comprising calcium carbide furnace 1, launder 2, smoke hood 3, calcium carbide pot 4, calcium carbide liquid 5, gas delivery device 6, gas source outlet pipe 7, and air distribution 8, flue 9, first dust collector 10, first dust collector outlet pipe 11, heat exchange device 12, heat exchange device outlet pipe 13, second dust collector 14, second dust collector outlet pipe 15, induced draft fan 16 , temperature probe 17, chimney 18, first control cabinet 19a, second control cabinet 19b, camera 20, lifting device 30;

[0038] The calcium carbide furnace 1 communicates with one end of the launder 2, and the other end of the launder 2 extends obliquely to the calcium carbide pot 4, and the calcium carbide liquid 5 flows into the calcium carbide pot 4 from the calcium carbide furnace 1 through the launder 2.

[0039] The fume hood 3 is suspended directly above the...

Embodiment 2

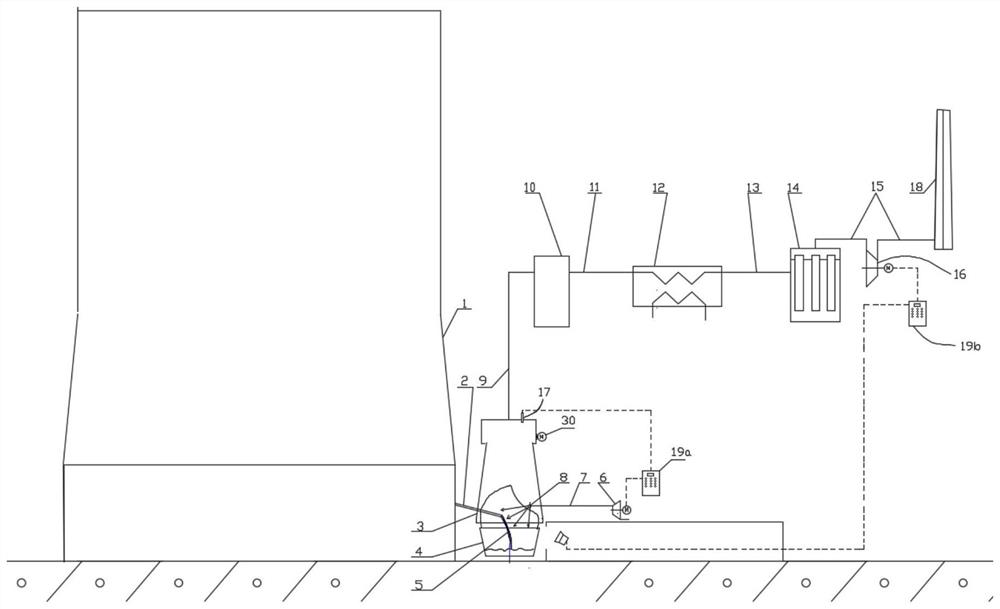

[0048] refer to figure 2 , the difference between Embodiment 2 and Embodiment 1 is that

[0049] Also includes a lifting device 30, the lifting device 30 is connected with the fume hood 3, the lifting device 30 is used to control the lifting of the fume hood 3, and then adjust the distance between the fume hood 3 and the calcium carbide pot 5, and change the distance between the fume hood 3 and the calcium carbide pot 4 The gap between them can change the suction volume of the dust removal air and increase the temperature after the blast and dust removal air are mixed.

[0050] Further, a method for recovering the heat of flowing calcium carbide in the furnace by combined blowing and induced wind includes the following steps:

[0051] Step 1), the combined system for recovering the heat of flowing calcium carbide is assembled;

[0052] Step 2), adjust the direction of the nozzle so that the direction of the blast jet is the launder, the falling calcium carbide, the calcium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com