Supercharging device used in drill rod and fluid jet guide drilling tool

A technology of pressurization device and fluid injection, which is used in drilling with liquid/gas injection, drill pipe, and directional drilling. , to avoid failure, the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

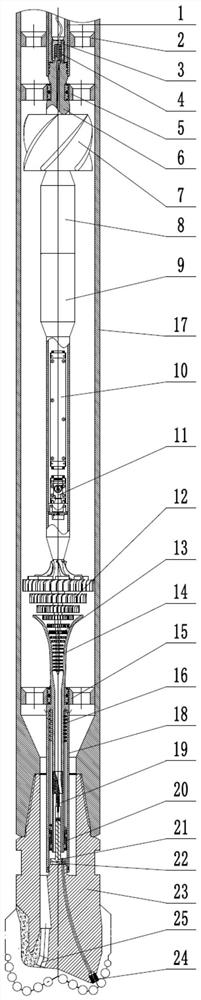

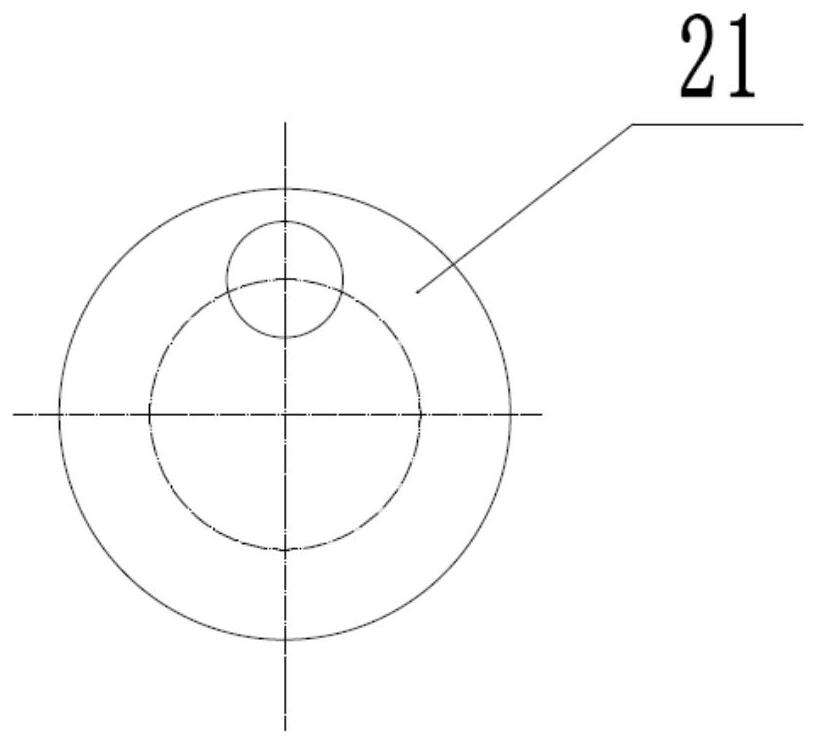

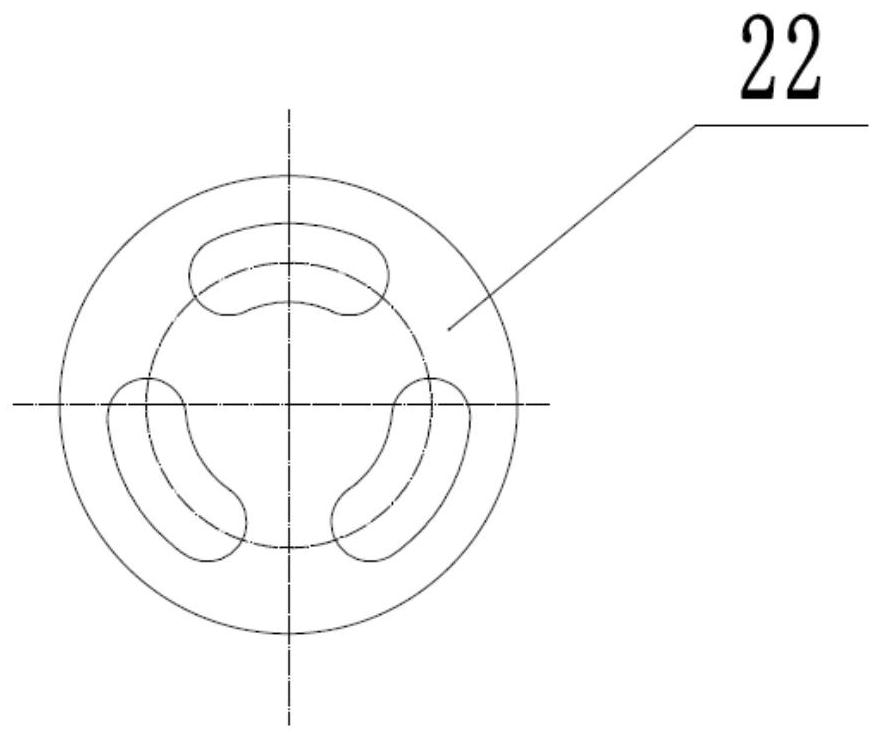

[0033] Such as Figure 1-4 Shown, a kind of pressurization device used in the drill pipe, the pressurization device includes the first power unit connected with the drill pipe collar: the upper turbine 7, the second power unit rotatably arranged with the drill bit 23, the second The power device includes: a power turbine 12, a compression turbine 13 integrated with the power turbine 12 and placed in the turbine cavity 14, the bottom of the turbine cavity 14 is connected to the high-pressure nozzle 24 on the drill bit 23 through a valve plate group; the drilling fluid flow power Down, the upper turbine 7 and the power turbine 12 rotate in the opposite direction, part of the drilling fluid enters the turbine cavity 14 under the action of the power turbine 12 of the second power unit, is pressurized by the compression turbine 13 and then sprayed out through the drill bit 23, realizing non-power increasing pressure.

[0034] For better supercharging effect, the cavity of the turb...

Embodiment 2

[0042] This embodiment is an intermediate connection structure added on the basis of Embodiment 1. Regarding the first power device, the second power device, the high pressure chamber 18, the pressure rod 19, the piston 20, the upper valve plate 21, and the lower valve plate 22 are here No more details, this embodiment focuses on the description of the regulating device connected between the first power device and the second power device; the regulating device is further optimized on the basis of Embodiment 1 to ensure that the second power device is always at rest Or the state of slightly swinging from side to side ensures that the supercharging structure is stable and effective.

[0043] The regulating device in the present embodiment comprises the generator 8 connected in turn with the upper turbine 7, the stabilizing motor 9, the measurement and control circuit board 10 and the attitude sensor 11, and the measurement and control circuit board 10 and the attitude sensor 11 a...

Embodiment 3

[0045] A fluid jet steering drilling tool, the fluid jet steering drilling tool includes the pressure boosting device used in the drill pipe of the first embodiment or the second embodiment, and for the specific technical solution of the boosting device, see the first embodiment and / or the implementation Example 2, this embodiment will not go into details, this embodiment focuses on the detailed description of the structure that cooperates with the boosting device and the technical details of the fluid jet steering drill including the booster device.

[0046] In addition to the supercharging device, the fluid jet guiding drilling tool in this embodiment also includes an outer cylinder 17 sleeved on the periphery of the supercharging device, a drill collar connected to the upper end of the outer cylinder 17, a drill bit 23 connected to the lower end of the outer cylinder 17, and a drill bit No high-pressure nozzles 24 and low-pressure water holes 25 are installed in the 23, part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com