Ocean wind power generation single pile foundation scouring protection device

A single-pile foundation and protection device technology is applied in the field of offshore wind power to achieve the effects of strengthening the blocking effect, saving costs, and increasing the production of aquaculture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

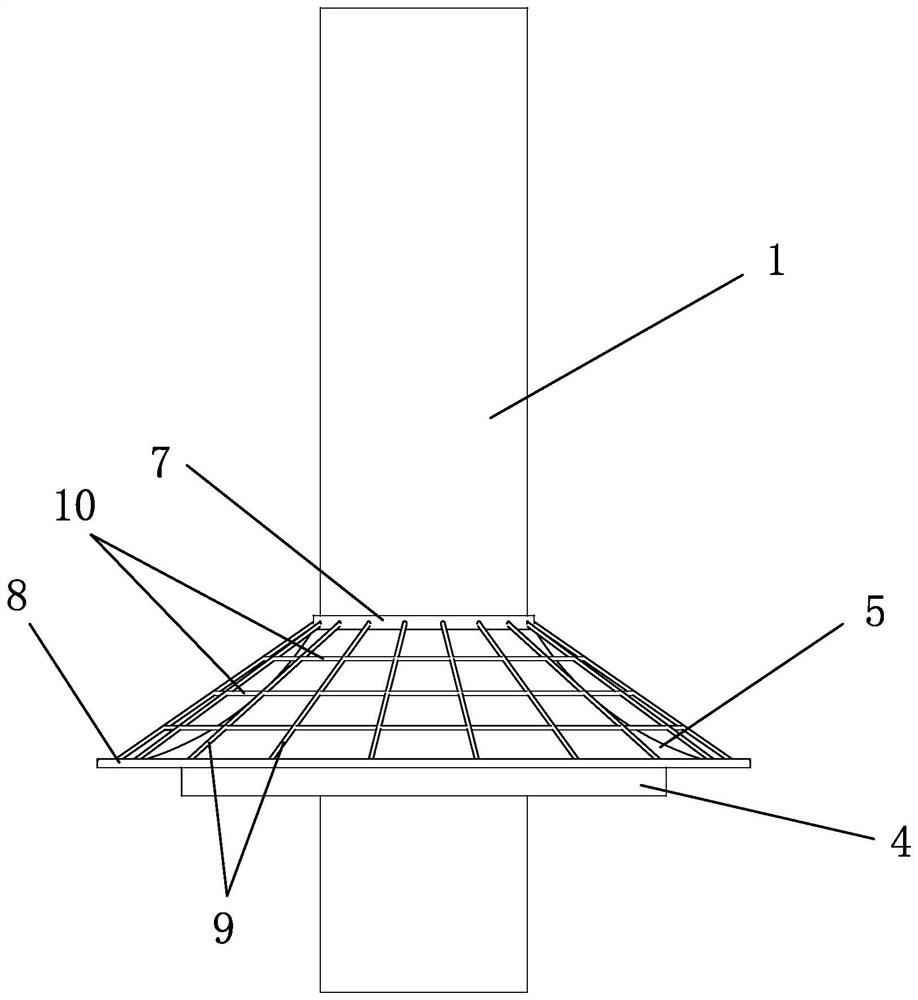

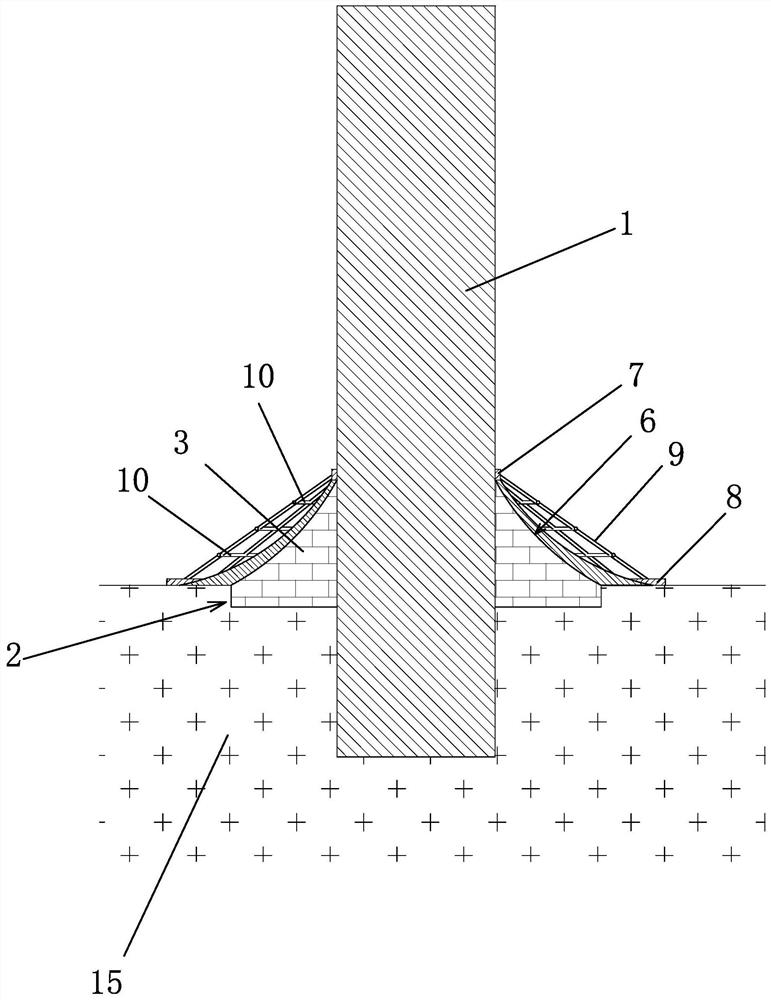

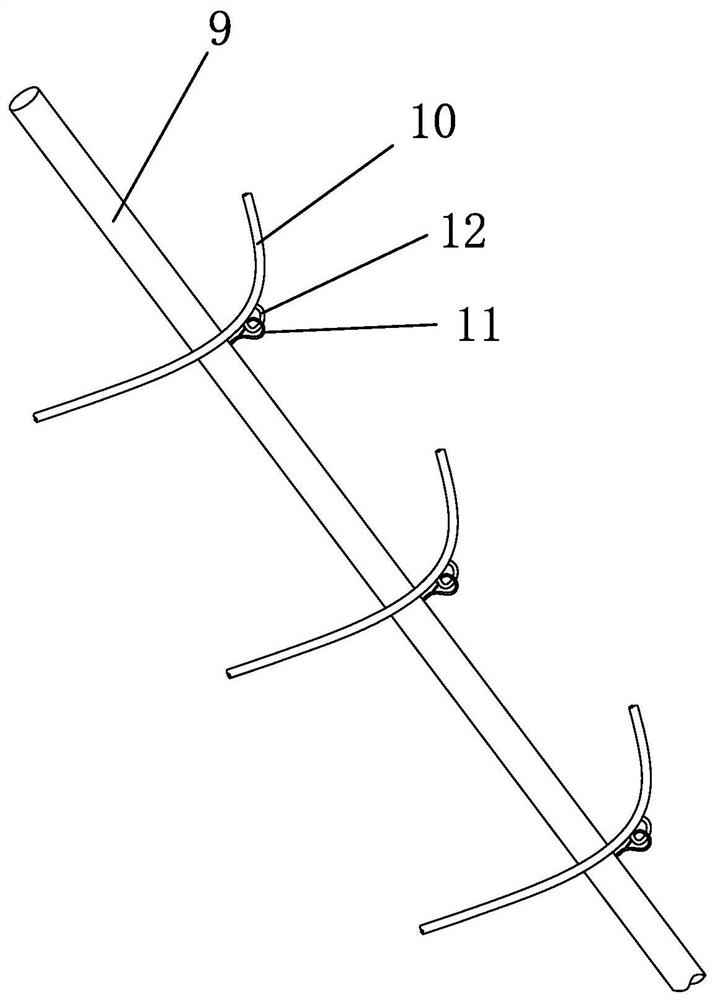

[0021] Such as Figure 1-Figure 3 As shown, the marine wind power monopile foundation erosion protection device includes a backfill gravel layer 2 surrounding the periphery of the monopile foundation 1. The backfill gravel layer 2 includes a conical rockfill layer 3 above the surface of the seabed 15 and a The soil-burrowed rock-fill layer 4 below the surface of the seabed 15, and the surface of the cone-shaped rock-fill layer 3 are covered with a buffer layer 5.

[0022] The buffer layer 5 is filled and cemented on the outer periphery of the conical rockfill layer 3 by means of grouting with cementitious materials. Using the grouting method, the buffer layer 5 has good integrity and is not easily damaged. A certain pressure, such as 0.5-1.5 MPa, is properly applied during the grouting process to improve the grouting effect and make the cemented buffer layer 5 more compact and durable. The cementitious material is a hydraulic cementitious material, including Portland cement, ...

Embodiment 2

[0028] Such as Figure 4 As shown, another marine rescue system based on the Internet of Things provided by the second embodiment of the present invention, the system is improved on the basis of the system structure of the first embodiment above: the lower support ring 8 is also provided with a breeding system surrounding the buffer layer 5 The net cage 13 constitutes a culture space 14 for cultivating fry between the culture net cage 13 and the culture rope 10 . In this way, the polyculture of marine economic crops and fish can not only reduce feed feeding, but also nourish marine economic crops with fish feces, which is conducive to the long-term stable operation of marine ranches and compensates for the impact on the sea area environment during the construction of wind farms. and resource damage.

[0029] The principle of use of the present invention is as follows: the marine economic crops on the breeding net build the first line of anti-scouring defense. When the ocean c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com