Smelting method of steel for automobile suspension spring

A technology of automobile suspension and steel smelting, which is applied in the manufacture of converters, etc. It can solve the problems of large width of inclusions, high oxygen content of molten steel, and different plastic sizes of inclusions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

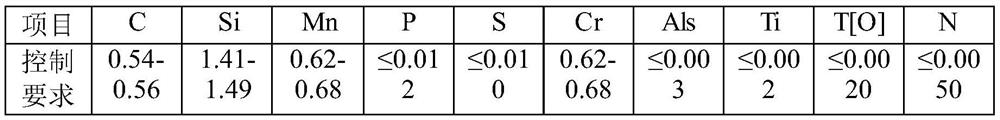

Embodiment 1

[0054] A method for smelting 55SiCr spring steel. The S content of molten iron is 0.002wt% before desulfurization pretreatment, and low-sulfur, low-aluminum, low-titanium high-quality steel scrap is added according to the ratio of scrap steel to molten iron of 0.26:1, so as to ensure that the S content at the end of the converter meets the requirements. Converter smelting adopts double slag smelting, the end point carbon is 0.16wt%, 5 tons of steel is left; 18kg / ton of high-purity ferrosilicon, which accounts for 85wt% of the total amount of ferrosilicon added to smelting, and 5.95kg / ton of low-titanium and high-carbon ferrochrome are added during tapping. per ton of steel, 5.43kg / ton of low-carbon ferromanganese, and 2.25kg / ton of low-nitrogen recarburizer for deoxidation alloying. After that, 3.17kg / ton of lime is added to the converter for tapping, and the basicity of the slag is 3.7. The operation of steel retention is adopted in the tapping of the converter, and the slag ...

Embodiment 2

[0056] A method for smelting 55SiCr spring steel, the S content of which is 0.002wt% is pretreated before molten iron is put into the furnace, and high-quality scrap steel with low sulfur, low aluminum and low titanium is added according to the ratio of scrap steel to molten iron of 0.27:1, so as to ensure that the S content at the end of the converter meets the requirements. Converter smelting adopts double slag smelting, the end point carbon is 0.15wt%, 4.5 tons of steel is left; 18kg / ton of high-purity ferrosilicon, which accounts for 86wt% of the total amount of ferrosilicon added to smelting, and 6.35kg / ton of low-titanium and high-carbon ferrochrome are added during tapping. per ton of steel, 5.83kg / ton of low-carbon ferromanganese, and 2.25kg / ton of low-nitrogen recarburizer for deoxidation alloying. After that, add lime 3.17kg / ton to the steel slag in the converter to control the basicity of the slag at 3.8. The operation of steel retention is adopted in the tapping of...

Embodiment 3

[0058] A method for smelting 55SiCr spring steel. S content of 0.003wt% is pretreated before molten iron is put into the furnace. Low-sulfur, low-aluminum, low-titanium high-quality steel scrap is added according to the ratio of scrap steel to molten iron of 0.29:1, so as to ensure that the S content at the end of the converter meets the requirements. Converter smelting adopts double slag smelting, the end point carbon is 0.17wt%, 5 tons of steel is left; 21kg / ton of high-purity ferrosilicon, accounting for 90wt% of the total amount of ferrosilicon added to smelting, and 6.13kg / ton of low-titanium, high-carbon ferrochrome are added during tapping. per ton of steel, 5.54kg / ton of low-carbon ferromanganese, and 2.45kg / ton of low-nitrogen recarburizer for deoxidation alloying. Afterwards, 2.97kg of lime is added to the converter to control the basicity of the slag at 3.9. The operation of steel retention is adopted in the tapping of the converter, and the slag of the converter is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com