Graphite-silicone rubber composite material and preparation method thereof

A composite material and silicone rubber technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of poor thermal conductivity and good thermal conductivity between surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

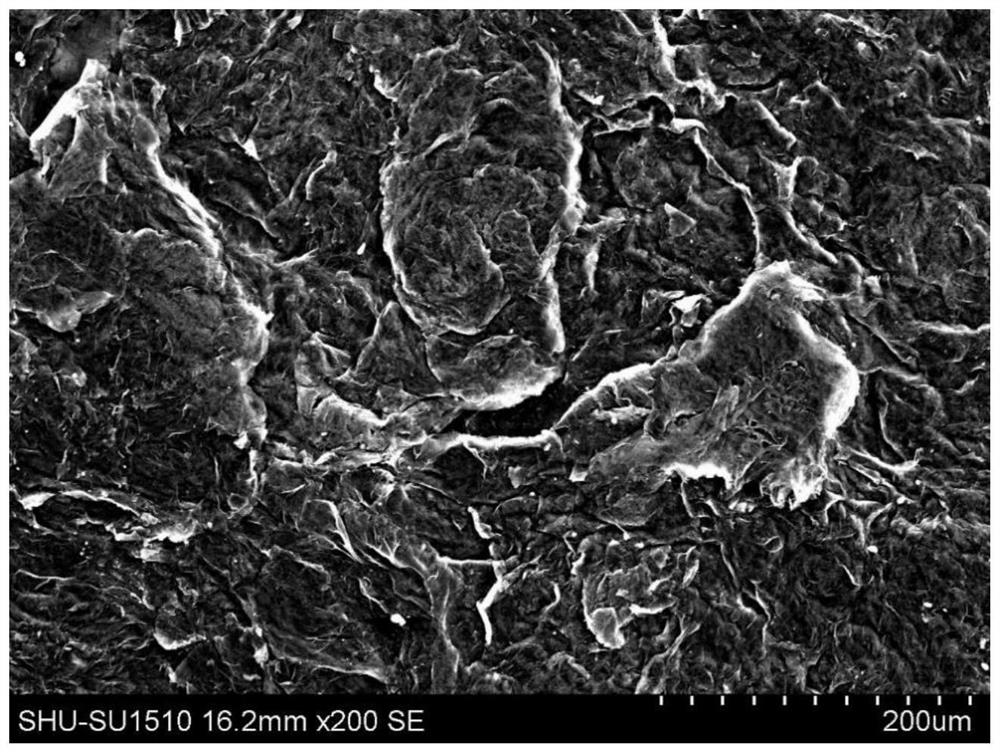

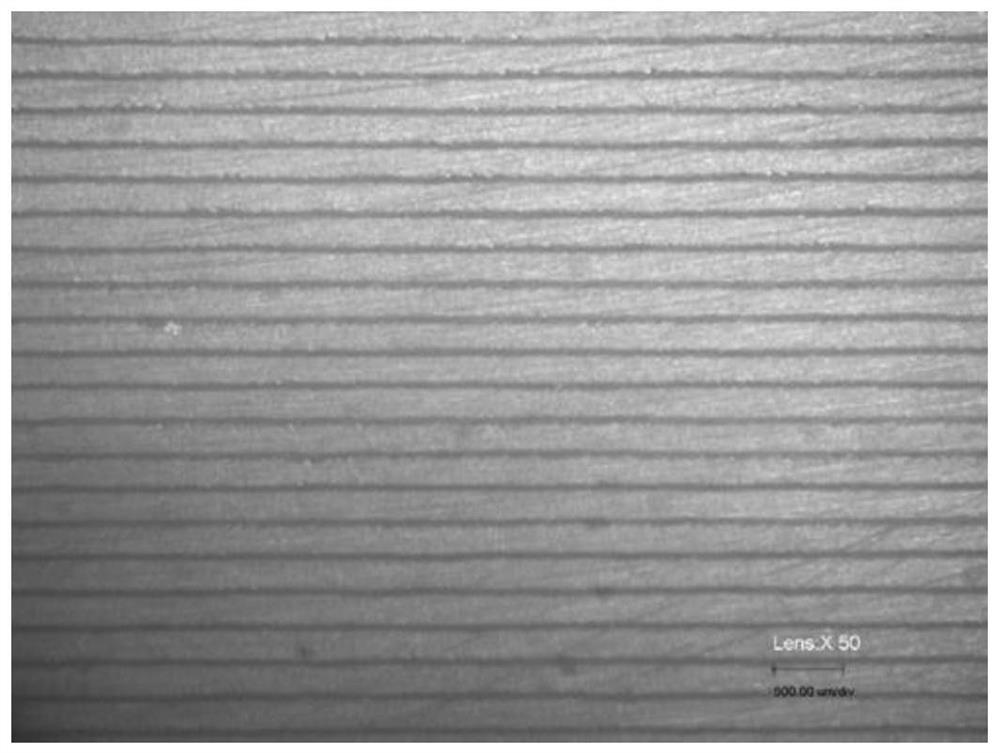

[0039] In a specific embodiment, the present application provides a method for preparing a graphite-silicone rubber composite material based on a graphite substrate. The graphite-silicon rubber composite material described in the present invention is a multi-layer composite material filled with graphite paper and silicone rubber. Forming a sandwich composite material, the specific steps are as follows:

[0040] a. Use graphite paper with a purity greater than 99% as the substrate;

[0041] b. Place the substrate described in a in 55-75°C alkaline degreasing water for ultrasonic oscillation, and use distilled water for cleaning after completion;

[0042] c. Use absolute ethanol or acetone as a solvent to prepare a KH-550 solution with a mass fraction of 5-20%;

[0043] d. Soak the cleaned graphite paper in the prepared KH-550 solution in step c, and then take it out to dry;

[0044] e. place a layer of the graphite paper obtained by step d that is spread;

[0045] f. spray a...

Embodiment 1

[0065] In the present embodiment, a preparation method of a graphite-silicon rubber composite material is provided, comprising the following steps:

[0066] a. Select graphite paper with a purity greater than 99.99% and a thickness of 0.231mm as the base material.

[0067] b. Place the substrate in alkaline degreasing water (concentration 30%) at 55°C with ultrasonic vibration for more than 30 minutes, and rinse and clean with distilled water several times after completion;

[0068] c. Use absolute ethanol as a solvent to prepare a KH-550 solution with a mass fraction of 8% for surface modification of the substrate;

[0069] d. Soak the cleaned graphite paper in the KH-550 solution in step c for more than 60 minutes, then take it out, put it into a hot air box and dry it for more than 60 minutes at a temperature of more than 80°C;

[0070] e. place a layer of graphite paper that is spread evenly and obtained by the above step d;

[0071] f. spray a layer of methyl vinyl sili...

Embodiment 2

[0079] In the present embodiment, a preparation method of a graphite-silicon rubber composite material is provided, comprising the following steps:

[0080] a. Select graphite paper with a purity greater than 99.99% and a thickness of 0.367mm as the base material.

[0081] b. Place the substrate in alkaline degreasing water (50% concentration) at 75°C for ultrasonic oscillation for more than 30 minutes, and rinse with distilled water for several times after completion;

[0082] c. Use absolute ethanol as a solvent to prepare a KH-550 solution with a mass fraction of 20% for surface modification of the substrate;

[0083] d. Soak the cleaned graphite paper in the KH-550 solution in step c for more than 60 minutes, then take it out, put it into a hot air box and dry it for more than 60 minutes at a temperature of more than 80°C;

[0084] e. place a layer of graphite paper that is spread evenly and obtained by the above step d;

[0085] f. spray a layer of methyl vinyl silicone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com