Coded disc mounting and positioning device of photoelectric non-contact ship shaft power meter

A photoelectric code disc, installation and positioning technology, applied to workpiece clamping devices, manufacturing tools, etc., can solve problems such as eccentricity errors, measurement result errors, and non-perpendicular axes, so as to improve measurement accuracy, eliminate eccentricity errors, and solve installation errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

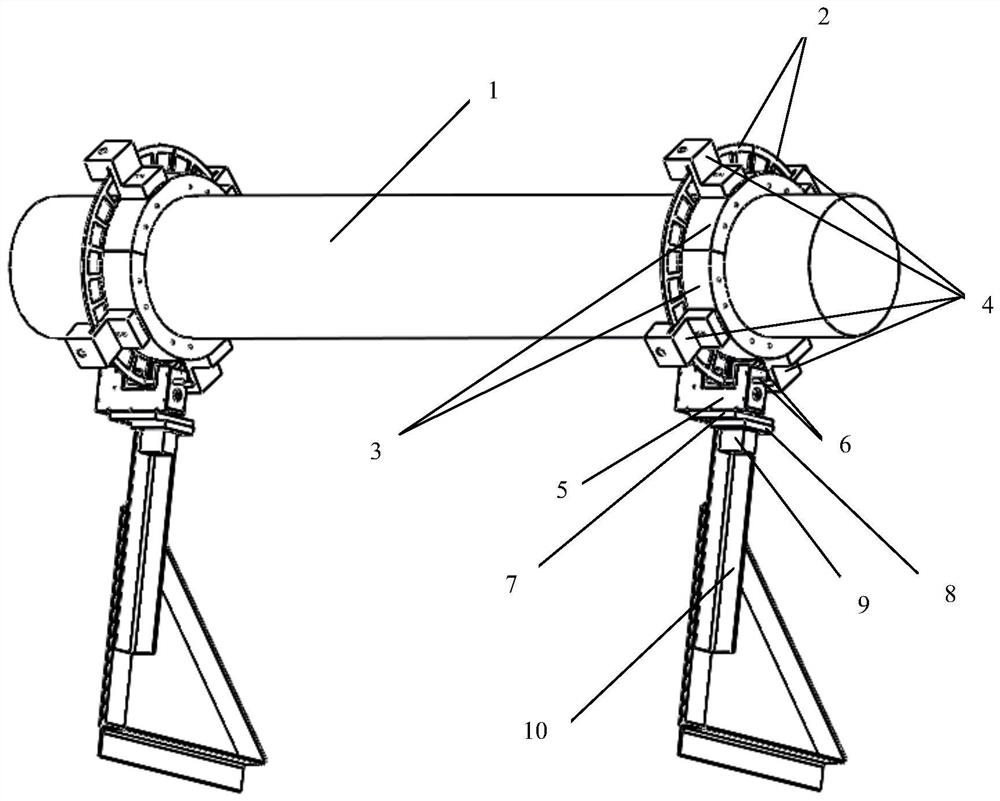

[0028] Such as Figure 1 to Figure 5 As shown, the code disc installation and positioning device of a photoelectric non-contact ship shaft power meter according to the present invention includes a measured rotating shaft 1, and the two ends of the shaft body of the measured rotating shaft 1 are respectively equipped with photoelectric codes through fixed installation accessories. Disk assembly 2, the plane of the photoelectric code disk assembly 2 is set perpendicular to the axis of the measured rotating shaft 1, and the center of the photoelectric code disk assembly 2 is set coaxially with the axis of the measured rotating shaft 1, and the photoelectric code disk assembly 2 passes through The fixed component is fixed with a photoelectric sensor 5, and the photoelectric sensor 5 is connected to the fixed base or the fixed platform col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com