Large intelligent manufacturing production line

A technology of intelligent manufacturing and production line, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as inability to adapt to intelligent production of various processes, parts cannot be accurately transported, and production line process is single, etc., to achieve directional transmission Accurate, save manpower and material resources, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be further described below.

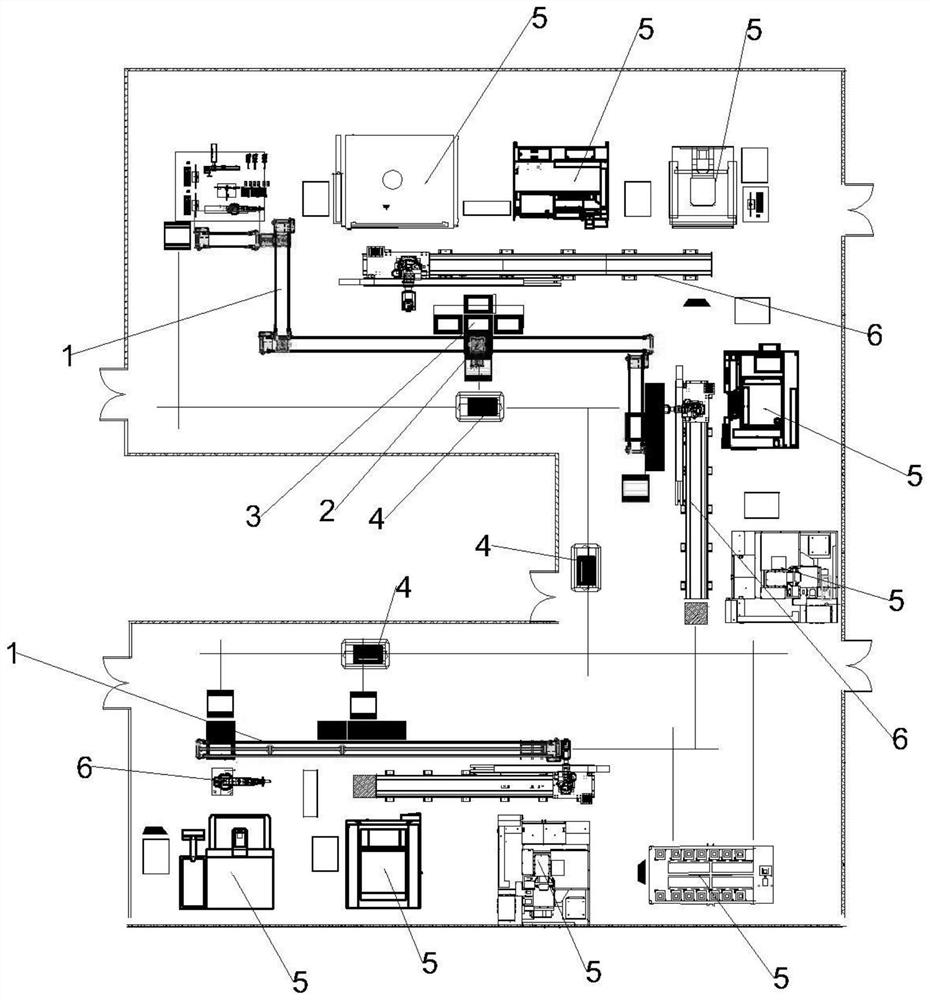

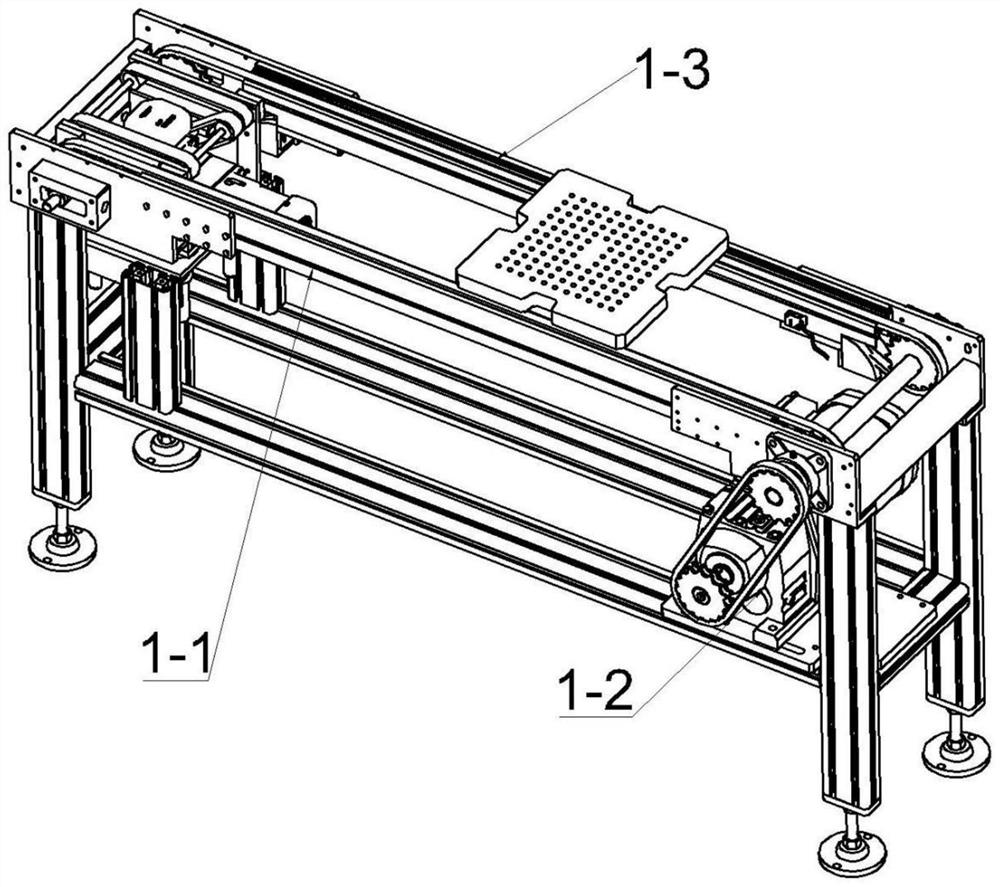

[0032] Such as figure 1 As shown, the present invention proposes a large-scale intelligent manufacturing production line, including a two-stage conveying main line 1, an AGV conveying robot 4, multiple machining centers 5 and a seven-axis robot 6;

[0033] The two sections of the main conveying line 1 are arranged at intervals, and the parts are conveyed through the AGV conveying robot 4 between the adjacent conveying main lines 1;

[0034] A plurality of machining centers 5 are arranged around the main conveying line 1 , and parts are transferred between the machining centers 2 and the main conveying line 1 through a seven-axis robot 6 .

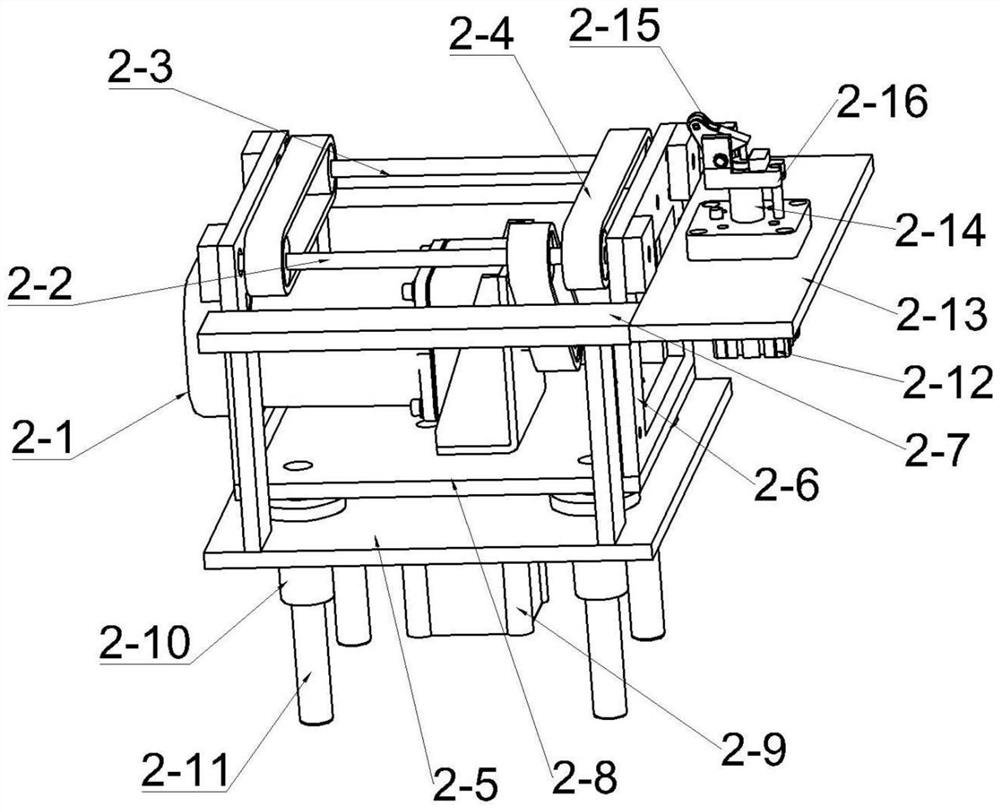

[0035] Further, a plurality of diversion lines are arranged on the outer edge of the main conveying line 1, and intelligent jacking mechanisms are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com