Stop tongue piece welding device and welding method thereof

A welding device and welding method technology, applied in welding equipment, welding equipment, auxiliary devices, etc., can solve the problems of difficult product assembly, large difference between the cold and heat of welding tools, and large heat-affected area, so as to improve product stability and performance. Reliability, good welding dimensional consistency, and small welding heat affected area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the technical solution of the present invention, the present invention will be described in connection with the drawings in the examples, and the embodiments described are only part of the present invention. Non-all, based on the present embodiment, those skilled in the art will be within the scope of the invention.

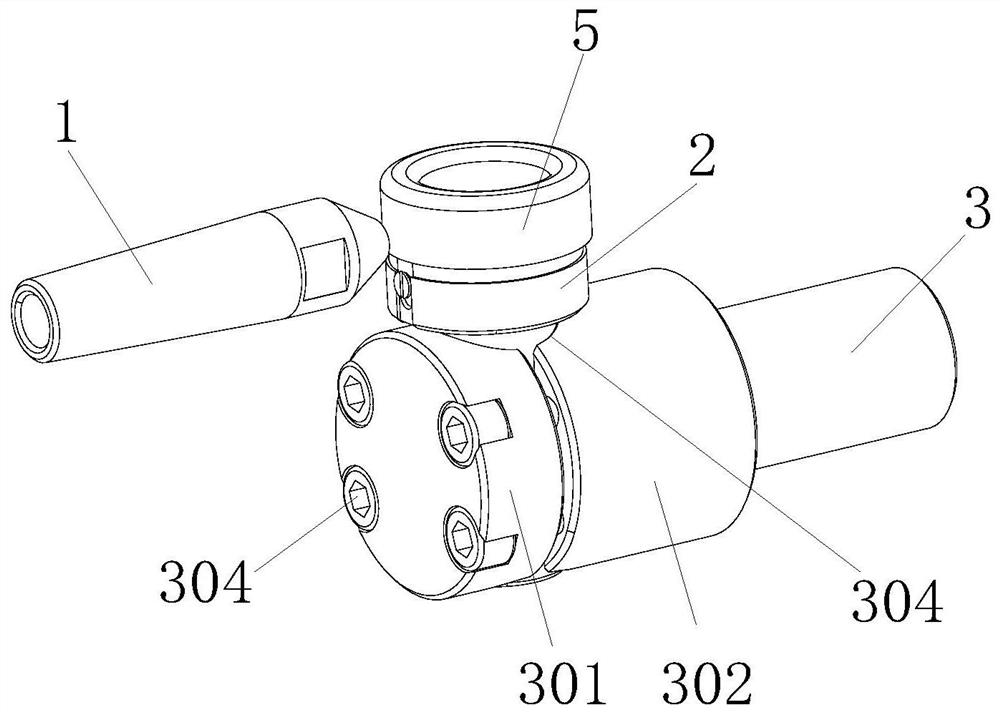

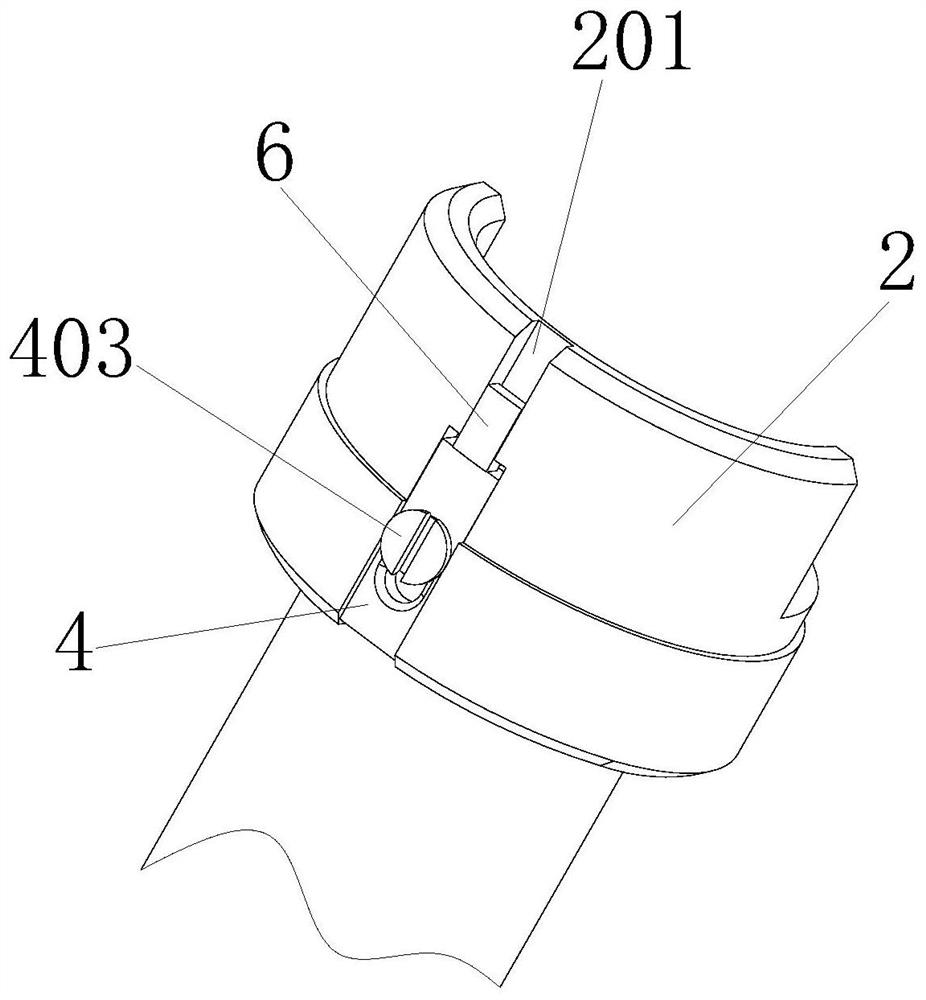

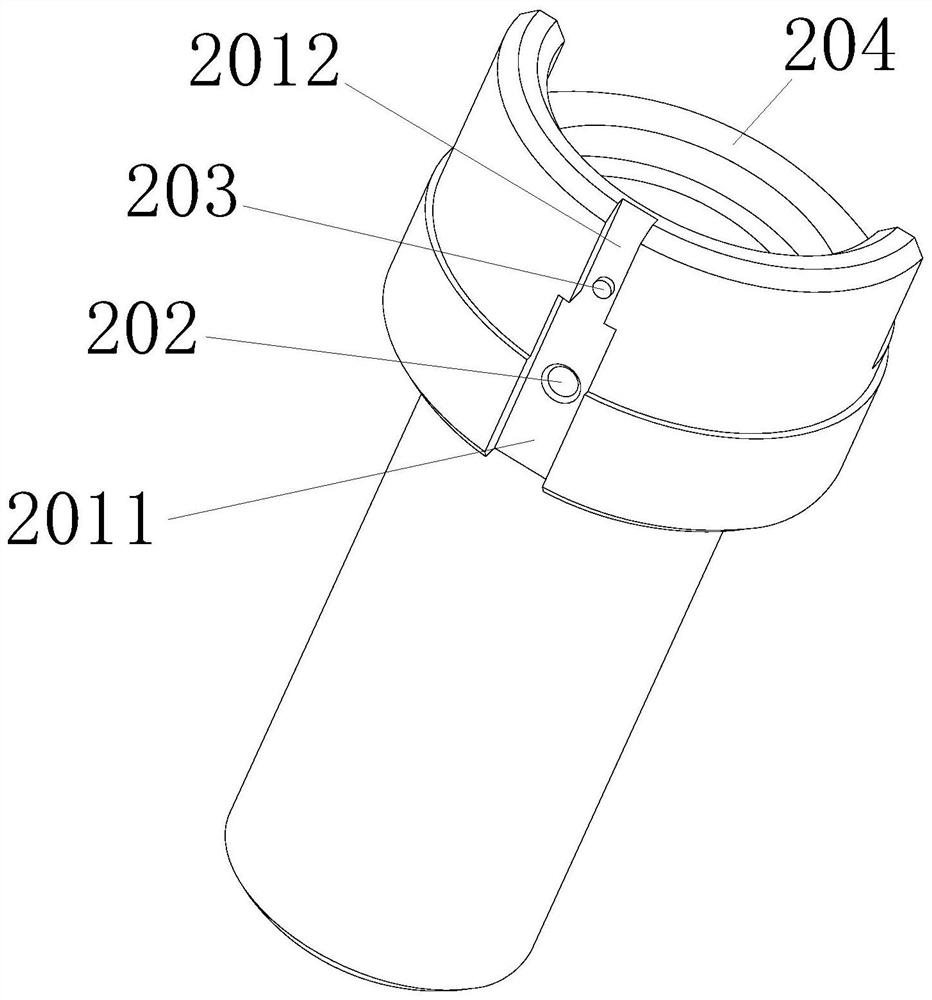

[0025] like Figure 1 to 5 As shown, a stop tongue welding device includes an upper electrode 1 and a lower electrode 2, and the lower electrode 2 is fitted with a base 3, and the lower electrode 2 is provided with a housing 5 with a stop tongue. The upper electrode 1 is provided with an outer cone 101 that is tightly fitted with the surface of the guard welding machine, and the lower electrode 2 is provided with a slide 201 of the storage stopper, and the slide groove 201 is sliding in the mounting stop. The positioning block 4 of the tongue position is also provided with a boss 203 against the stopper position to focus the weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com