A multi-stage crushing device for solid waste recycling

A crushing device and resource-based technology, applied in grain processing, etc., can solve the problems of increasing the power required for crushing, easy blockage, and inability to disperse and crush

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

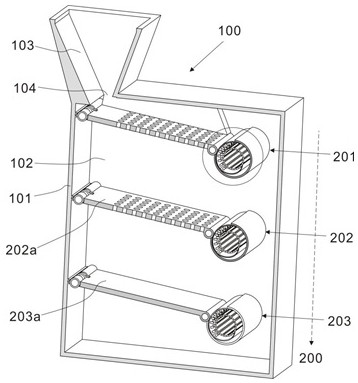

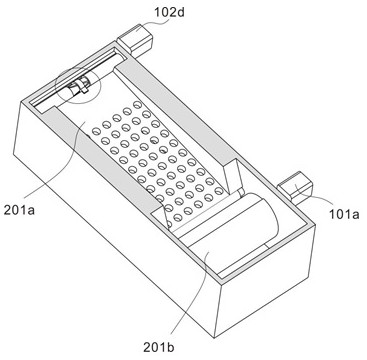

[0032] refer to Figures 1~5 , this embodiment provides a multi-stage crushing device for solid waste recycling treatment, including a casing assembly 100, including a box body 101 and an inner cavity 102 arranged inside the box body 101, the top of the box body 101 is provided with a feed The hopper 103, the feeding hopper 103 communicates with the inner cavity 102 through the feeding port 104; the crushing assembly 200 includes a primary crushing piece 201, a secondary crushing piece 202 and a tertiary crushing piece 203, a primary crushing piece 201, a secondary crushing piece 203 The crushing piece 202 and the tertiary crushing piece 203 are arranged in the inner cavity 102 in order from top to bottom. The primary crushing piece 201 includes a vibrating piece 201a and a shredding piece 201b. There are end pipes 102a on both sides of the inner cavity 102, and two rotating shafts 102b. The end is embedded in the end tube 102a, and the two ends of the vibrating member 201a ar...

Embodiment 2

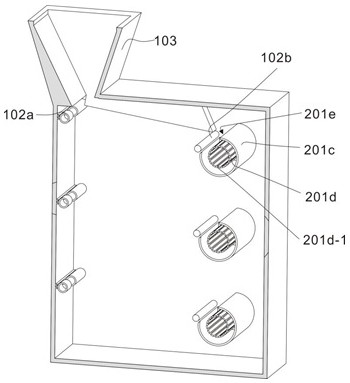

[0042] refer to Figures 1~7 The difference between this embodiment and the previous embodiment is that the shredding piece 201b includes an outer cylinder 201c and an inner cylinder 201d, the outer cylinder 201c is provided with an opening 201e, and the opening 201e is facing the first filter plate 201a-1 The end; the chopper 201b is provided with a slicer 201f, one end of the slicer 201f is connected to the second motor 101a through the box 101; the slicer 201f includes a retracted end 201f-1 near the inner side of the outer cylinder 201c and Polymerization end 201f-2 outside of barrel 201d.

[0043] Further, a cutter 201f-3 is provided on the inner side of the slicer 201f.

[0044] It should be noted that the inner cylinder 201d is provided with a circular hole 201d-1 for entering particles of a certain size, which reduces the crushing burden and avoids clogging caused by accumulation of small particles.

[0045] It should be noted that, in this embodiment, both the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com