Extrusion and crushing rod for auxiliary feeding device

A technology of extrusion crushing and shearing, which is applied in the direction of therapeutic feeding tubes and grain processing, etc. It can solve the problems that the crushing degree only reaches granulation, does not have food crushing ability, and has a single function, and achieves low wear and calorific value, Effect of increasing transmission volume and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. The advantages and features of the present invention will be more apparent from the following description. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

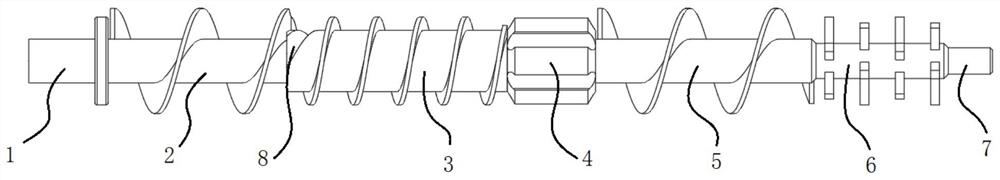

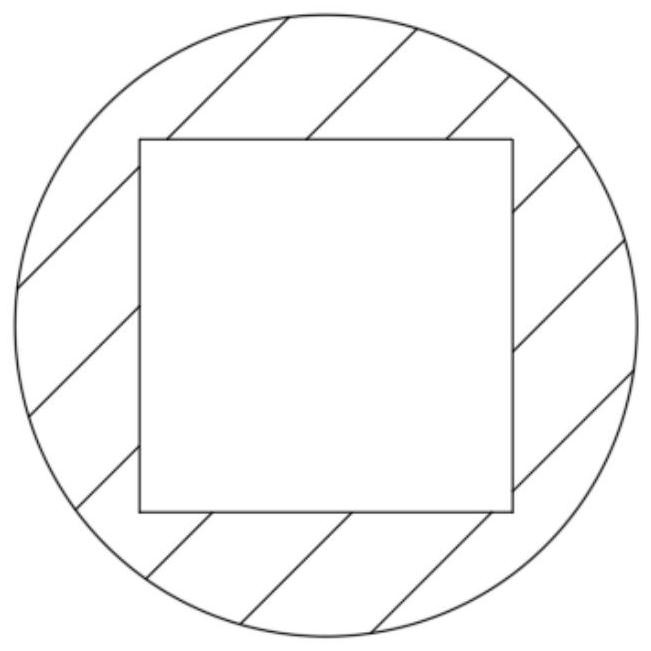

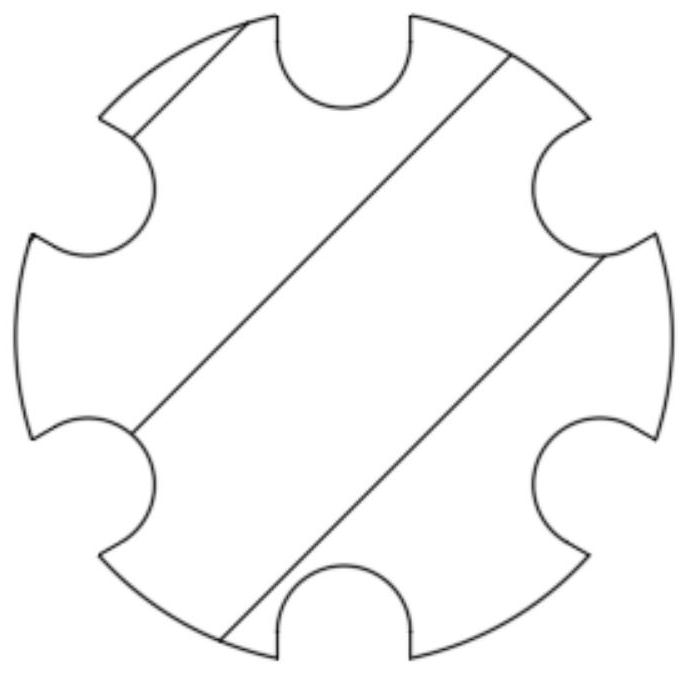

[0026] like Figure 1-Figure 3 As shown, a crushing rod for an auxiliary feeding device provided by an embodiment of the present invention is rotatably installed in a communication hole on the feeding assisting device, and the length-to-diameter ratio of the crushing rod is 22:1. The crushing rod is divided into connecting section 1, first conveying section 2, first shearing section 3, second shearing section 4, second conveying section 5, solid-liquid mixing section 6 and supporting section in the axial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com