Dental surface tartar cleaner for department of stomatology

A tooth surface and cleaner technology, applied in the field of cleaners, can solve problems such as insufficient cleaning of plaque, damage to teeth or gums, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

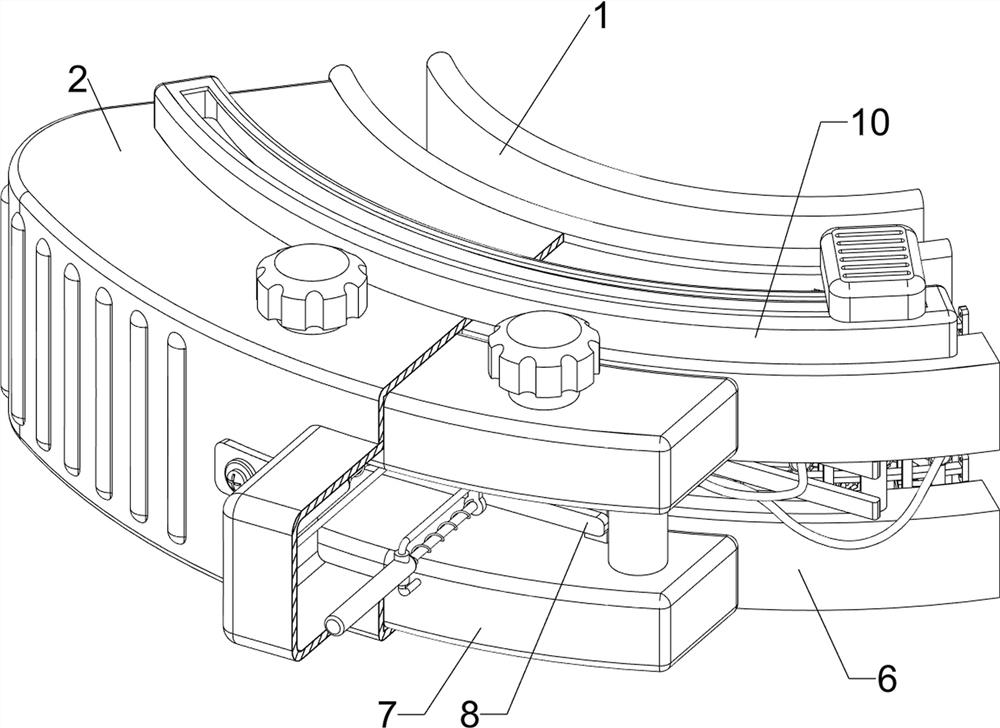

[0033] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a tooth surface tartar cleaner in stomatology department includes a dental cover 1, a shell 2, a cleaning brush 3, a motor 4, a brushing assembly 5 and a moving assembly 6, the dental cover 1 is provided with a shell 2, and the shell 2 is provided with a mobile Assembly 6, the moving assembly 6 is provided with a scrubbing assembly 5, the scrubbing assembly 5 is provided with a cleaning brush 3, and the scrubbing assembly 5 is provided with a motor 4.

[0034] When the user needs to clean the tartar of the teeth, the user bites the braces 1, and then the user starts the motor 4, the output shaft of the motor 4 rotates to drive the brushing assembly 5 to rotate, and the rotation of the brushing assembly 5 drives the cleaning brush 3 to rotate to scrub the user's tartar , while scrubbing, the rotation of the cleaning brush 3 drives the moving assembly 6 to move to the left. When the moving assembly 6 moves...

Embodiment 2

[0036] Such as image 3 , Figure 4 , Figure 5 and Figure 6 As shown, on the basis of Embodiment 1, the moving assembly 6 includes a missing gear 601, an arc-shaped rack 602, a guide rail 603, a slider 604 and an arc-shaped guide rod 605, and two cleaning brushes 3 are provided with a missing tooth. The gear 601 is symmetrically arranged with an arc-shaped rack 602 up and down inside the shell 2, and the two missing gears 601 cooperate with the two arc-shaped racks 602; A sliding block 604 is provided in a sliding manner, and arc-shaped guide rods 605 are arranged in the two guide rails 603 , and the sliding block 604 is slidably connected with the two arc-shaped guide rods 605 .

[0037]The scrubbing assembly 5 includes a support frame 501, a first support rod 502, a spur gear 503 and a toothed belt 504, the rear side of the slider 604 is symmetrically arranged with a support frame 501 up and down, and the two support frames 501 are rotatably provided with a cleaning bru...

Embodiment 3

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, on the basis of Embodiment 2, a spray assembly 7 is also included, and the spray assembly 7 includes a storage tank 701, a cylinder body 702, a piston 703, a first spring 704, a water outlet pipe 705, a water inlet pipe 706, and a hose 707, the second support rod 708 and the spray head 709, a storage tank 701 is arranged between the front sides of the two guide rails 603, a cylinder body 702 is arranged symmetrically up and down on the front side of the casing 2, and a piston 703 is slidingly arranged in the two cylinder bodies 702 , the first spring 704 is connected between the two pistons 703 and the two cylinders 702, the opposite sides of the two cylinders 702 are provided with water outlet pipes 705, and the opposite sides of the two cylinders 702 are provided with water inlet pipes 706, the two water inlet pipes 706 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com