Net pulling sleeve for optical fiber cable

A fiber optic cable and cable technology, which is applied in the field of net pull sleeves, can solve the problems of cable soaking and moisture, affecting the use of cables, etc., to achieve the effect of improving flexibility, ensuring the tightening effect, and increasing the upper limit of the traction force that can be tolerated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

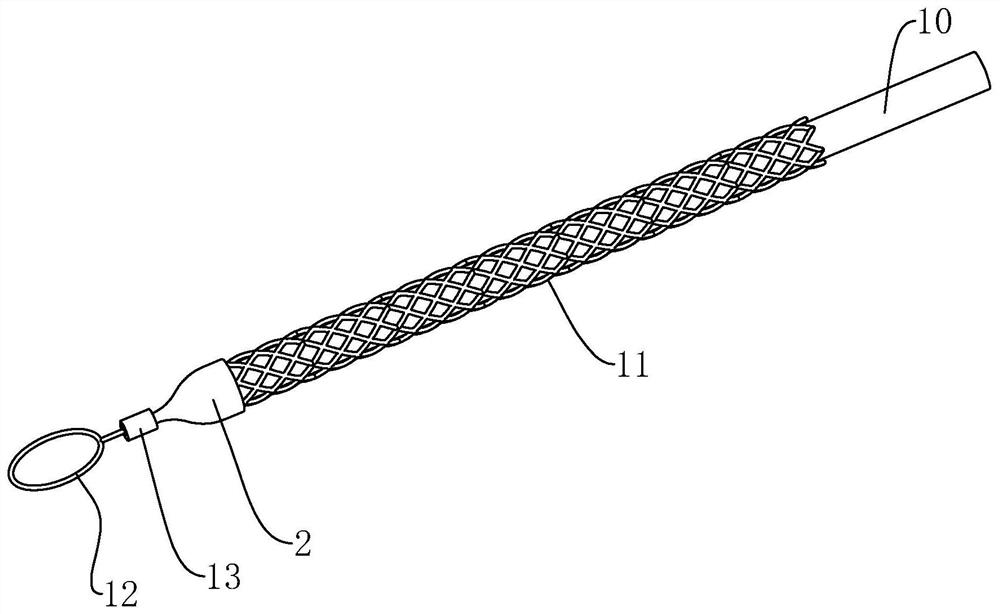

[0047] The implementation principle of Embodiment 1 is as follows: the exposed end of the cable 10 is sealed by setting the waterproof cover 2, so as to effectively prevent the intrusion of external water; In order to reduce the probability of the waterproof case 2 detaching, and the closed end of the waterproof case 2 is locked by the beam sleeve 13, so as to improve the waterproof effect.

Embodiment 2

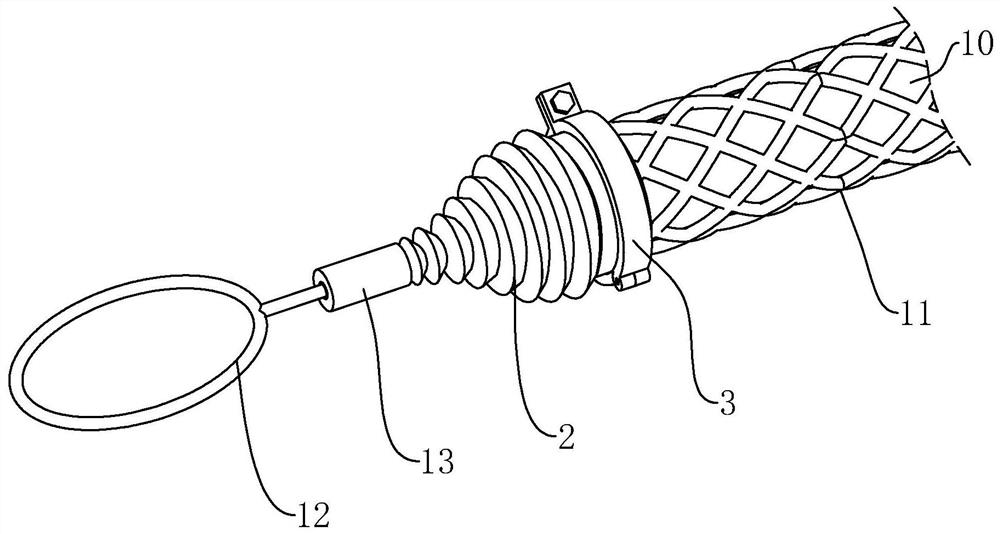

[0048] Embodiment 2 is different from Embodiment 1 in that, as image 3 As shown, the waterproof cover 2 is an elastic telescopic cover, which is made of rubber. When the cable 10 is placed in the steel wire rope net 11 and the steel wire rope net 11 is pre-tightened (at this time, the distance between the traction rope 12 and the end of the steel wire rope net 11 is pulled. Large), and then unfold the waterproof cover 2, so that the open end of the waterproof cover 2 extends to the position corresponding to the end of the cable 10 on the wire rope net 11, thereby realizing the sealing of the end of the cable 10, and its operation is convenient and quick.

[0049] Moreover, in order to further improve the sealing effect of the opening end of the waterproof sheath 2 on the end of the cable 10, after the waterproof sheath 2 is extended, a clamping member 3 can be sleeved on the outer wall of the opening end of the waterproof sheath 2, and the clamping member 3 can be a clamp , s...

Embodiment 3

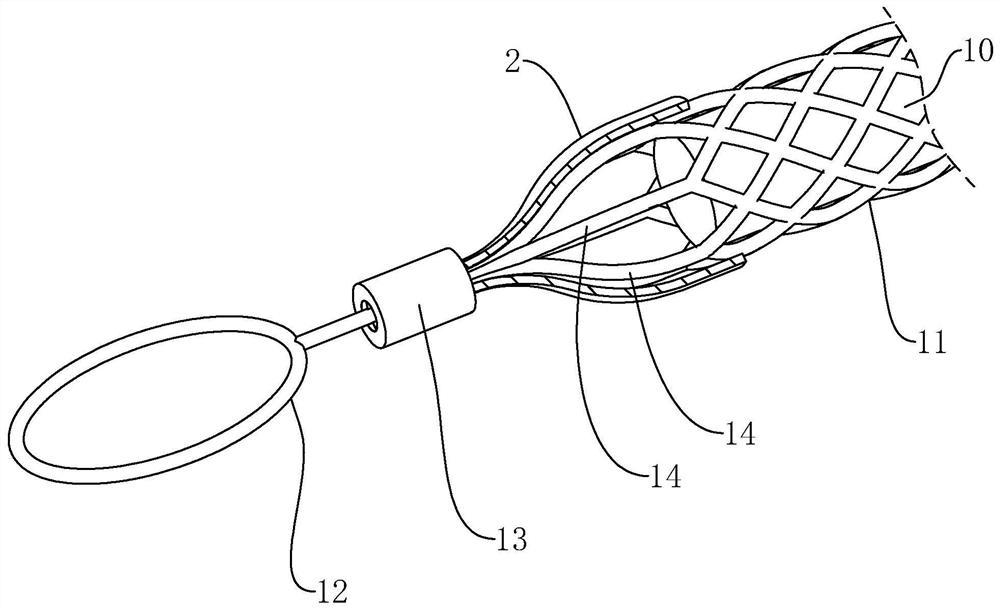

[0050] Embodiment 3 is different from Embodiment 1 in that, as Figure 4 As shown, the waterproof cover 2 can be made of elastic material, or hard plastic or metal material. The waterproof cover 2 in this embodiment is made of rubber material, and the waterproof cover 2 is located in the tapered accommodation cavity formed by the multi-strand connecting rope 14. Inside.

[0051] First, elastically wrap the opening end of the waterproof cover 2 on the outer wall of the end of the cable 10, then put the waterproof cover 2 and the cable 10 into the steel wire rope net 11 at the same time, at this time, the waterproof cover 2 is located in the accommodation cavity, and then pre-tighten the steel wire rope Net 11, steel wire rope net 11 is tightened and fixed to the outer wall of waterproof case 2.

[0052] By putting the waterproof case 2 into the accommodation cavity, firstly, the waterproof case 2 is protected through the connecting rope 14 and the steel wire netting 11, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com