Fully-enclosed condenser intelligent leakage detection device and method

A fully enclosed, condenser technology, which is applied in the direction of measuring devices, sampling devices, and electrical devices to test the fluid tightness, etc., can solve the problems of impurity gas leakage, inconvenient sealing, heavy workload, etc., to reduce Maintenance cost and workload, easy to fully enclosed and sealed, avoiding the effect of air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

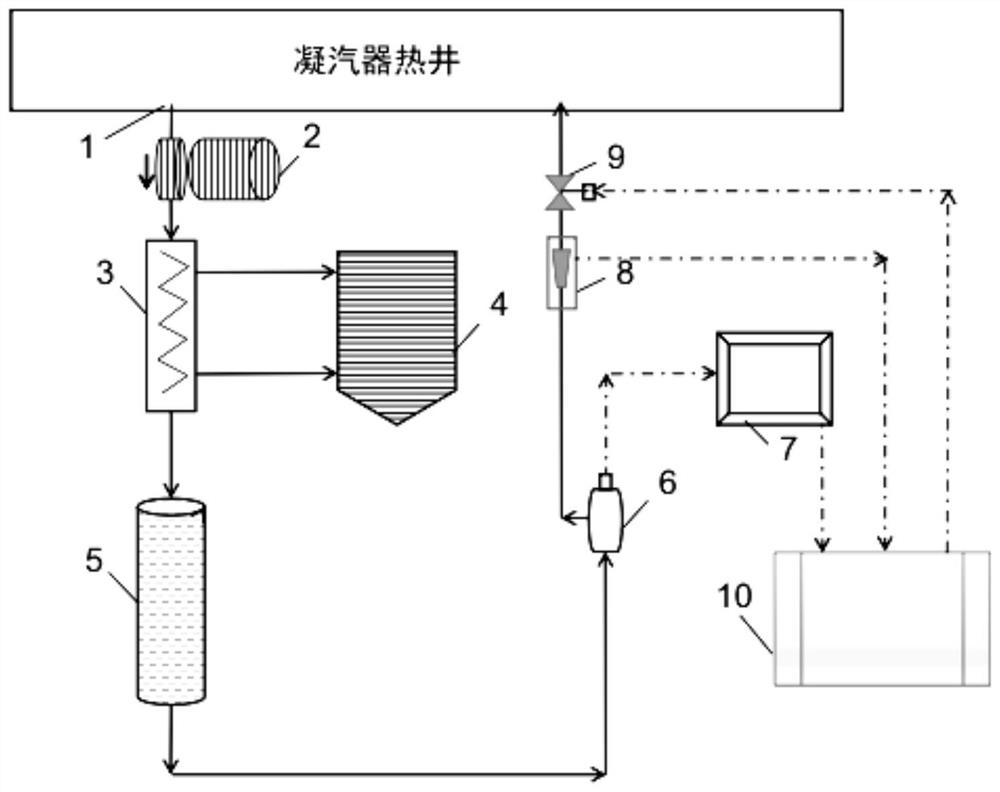

[0021] Such as figure 1 As shown, a fully enclosed condenser intelligent leak detection device of the present invention includes a plurality of intelligent leak detection devices distributed at different positions of the condenser hot well at the bottom of the condenser, and each intelligent leak detection device includes a condenser Steam boiler hot well sampling port 1, magnetic pump 2, sampling cooler 3, electric regenerative cation exchanger 5, conductivity measuring electrode 6, flow meter 8 and flow rate connected to condenser hot well sampling port 1 through pipelines The regulating valve 9 and the outlet of the flow regulating valve 9 are connected to the hot well of the condenser, and the conductivity measuring electrode 6 of each intelligent leak detection device is connected to the input end of the central data acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com