Detection system applied to tank fire control system

A fire control system and detection system technology, which is applied to the control system of guns, offensive equipment, weapon accessories, etc., can solve the problems of high labor cost, prolonged time, inconvenient operation, etc., so as to reduce labor cost and improve detection accuracy. , the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in detail below with reference to the accompanying drawings and examples.

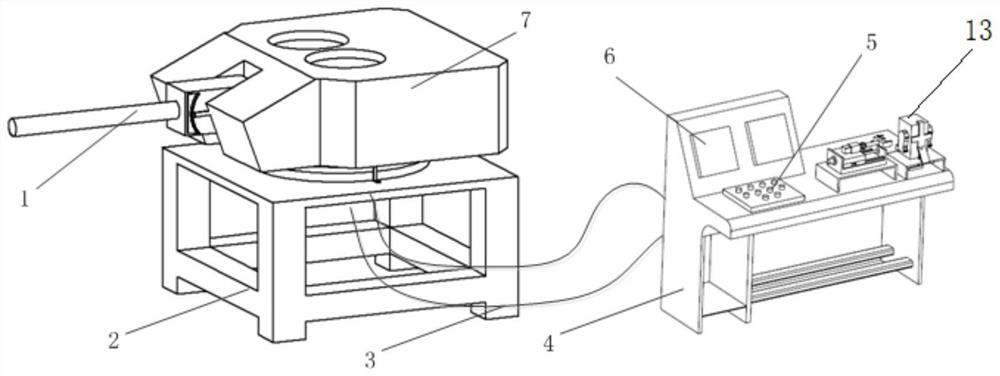

[0061] This embodiment provides a detection system applied to the tank fire control system, see the attached figure 1 , the tank comprises: a pedestal 2, a cannon 1 and a turret 7; the tail of the cannon 1 is installed on the front end of the turret 7 through a pin shaft, and the cannon 1 can rotate around the axis of the pin shaft, that is, carry out Pitching motion; the turret seat ring of the turret 7 is installed on the platform 2, and the turret 7 can rotate around the axis of the turret seat ring, that is, it drives the artillery to rotate horizontally;

[0062] The fire control system of the tank to be tested includes: fire control system control components and product console 13; the fire control system control components are installed in the turret 7, and are used to drive the artillery 1 for pitching and horizontal rotation;

[0063] The detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com