Reinforcing steel bar self-locking connector and self-locking connecting method

A technology of connectors and steel bars, which is used in buildings, building reinforcements, building components, etc., can solve problems such as unsuitable precast concrete structures, avoid aging and failure problems, facilitate installation, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in more detail below with reference to schematic diagrams, wherein preferred embodiments of the present invention are shown, and it should be understood that those skilled in the art can modify the present invention described herein while still achieving the advantageous effects of the present invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

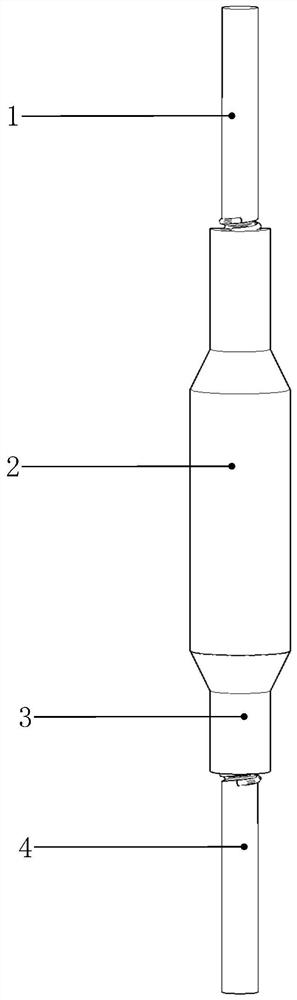

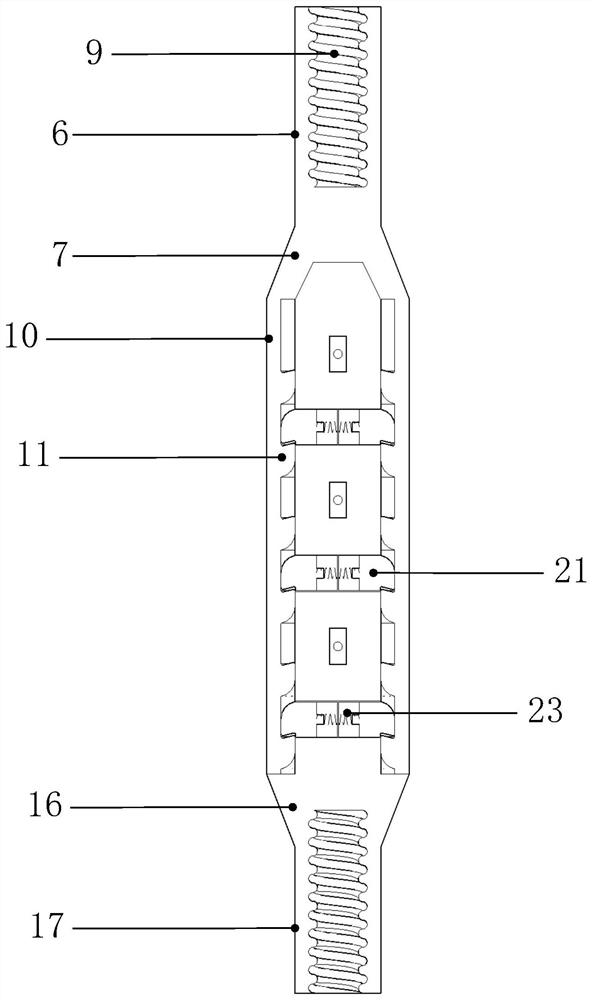

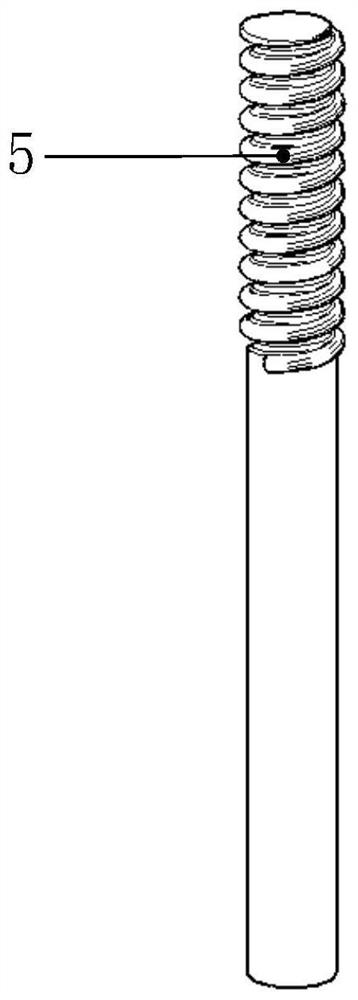

[0035] Such as Figure 1~10 , a steel bar self-locking connector, characterized in that it includes: an upper connecting rib 1, a lock cylinder 2, a lock cylinder 3, a lower connecting rib 4 and a bayonet unit 18. In other embodiments other than this embodiment, the two steel bars can also be arranged left and right.

[0036] Specifically, the upper connecting rib 1 is threadedly connected with the lock cylinder 2, the lower connecting rib 4 is threadedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com