Prefabricated prestressed high performance concrete composite beam and its construction method based on dry connection

A technology of high-performance concrete and prefabricated concrete, which is applied to the direction of long-strip structural members, girders, joists, etc. used for load-bearing, and can solve the problem that it is difficult to apply concrete completely and accurately for prestress, it is difficult to ensure prestress, and the construction process is complicated, etc. problems, to achieve the effect of saving materials, good maintenance, and enhancing the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings and examples.

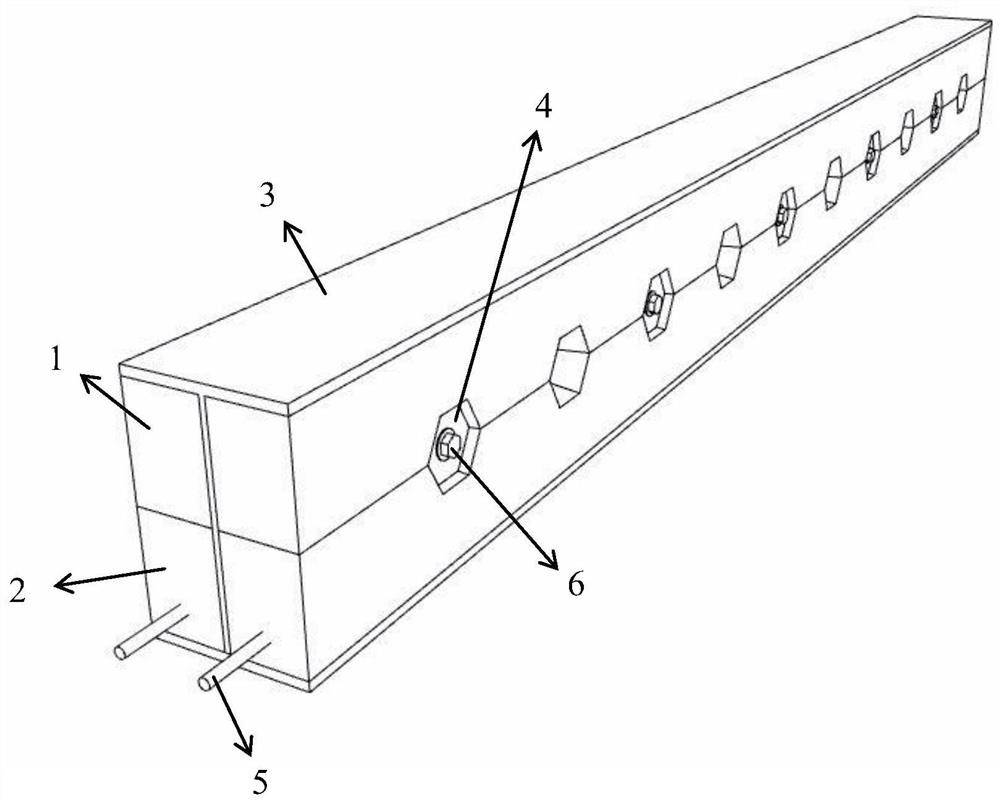

[0043] like figure 1 As shown, the present invention is a prefabricated prestressed high performance concrete composite beam based on dry connection, comprising:

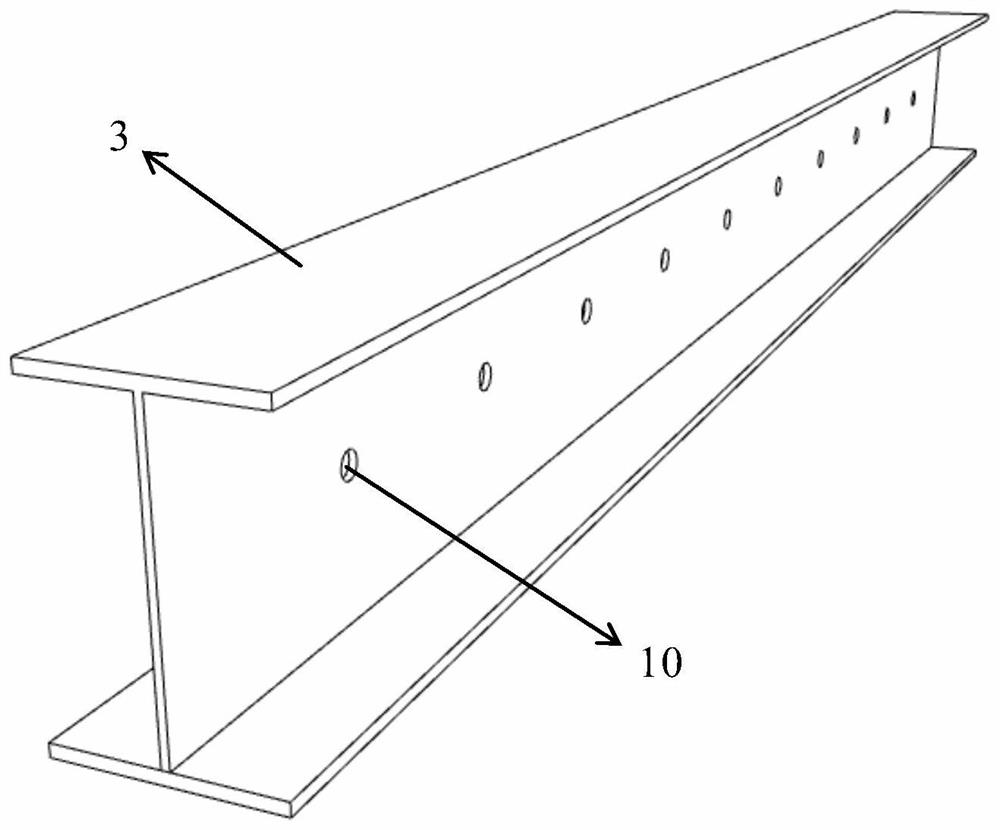

[0044] The I-beam 3 has several round holes 10 pierced through its web along the length direction, such as figure 2 As shown, from the upper flange to the lower flange, the circular holes 10 may be arranged in one row, and may also be arranged in multiple rows.

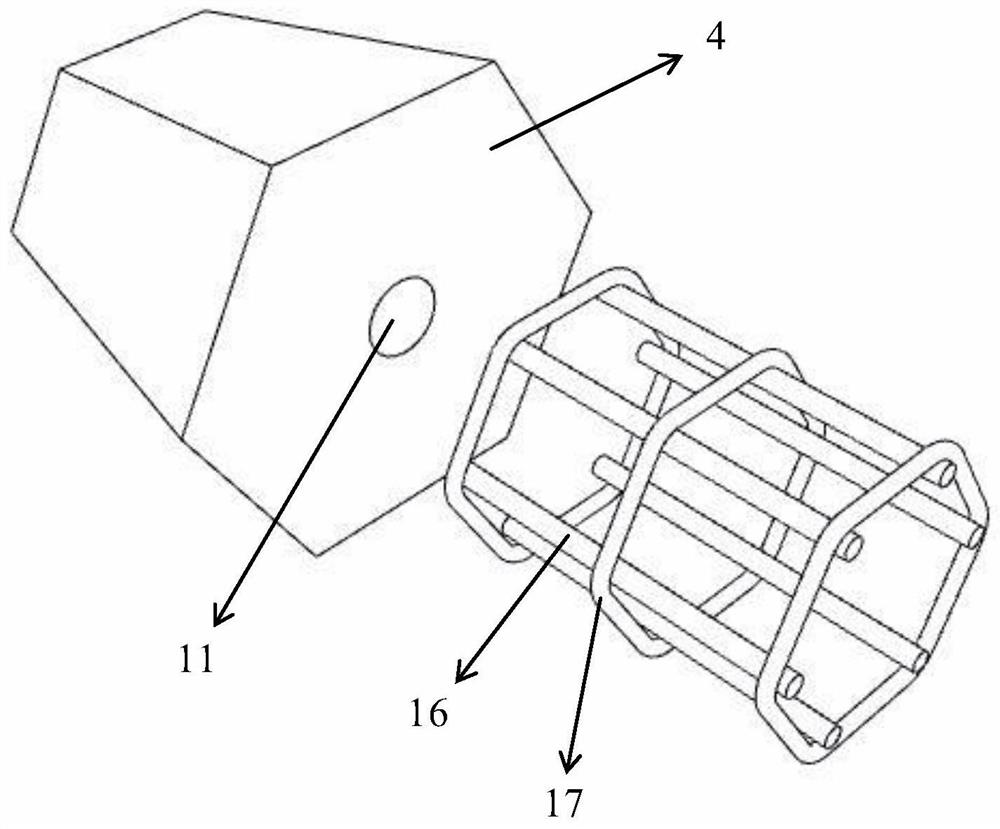

[0045] The split concrete strips are arranged on both sides of the web of the I-beam 3 and between the upper and lower flanges, and are provided with through holes, which are coaxial with the circular holes 10 . Wherein, the via hole on at least one side is a gradually widening hole, and the gradually widening hole means that the diameter of the via hole increases linearly along the direction from the web to the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com