Synthesis method of defective zeolite molecular sieve rich in hydroxyl nests

A zeolite molecular sieve, a technology rich in hydroxyl groups, applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminum silicate zeolite, etc., to achieve the effect of maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

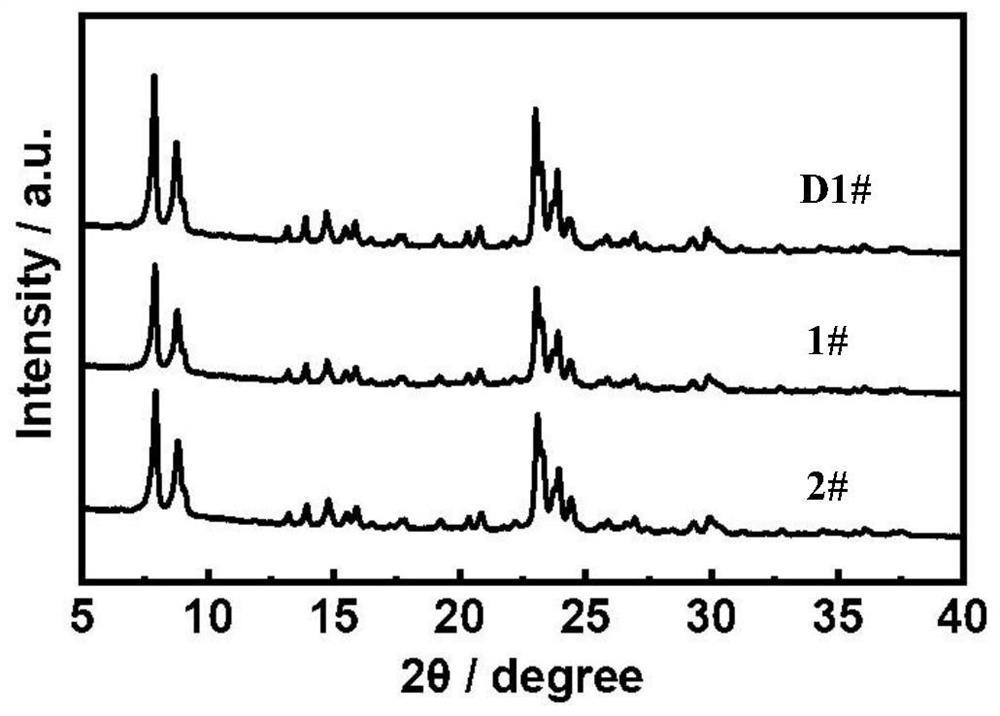

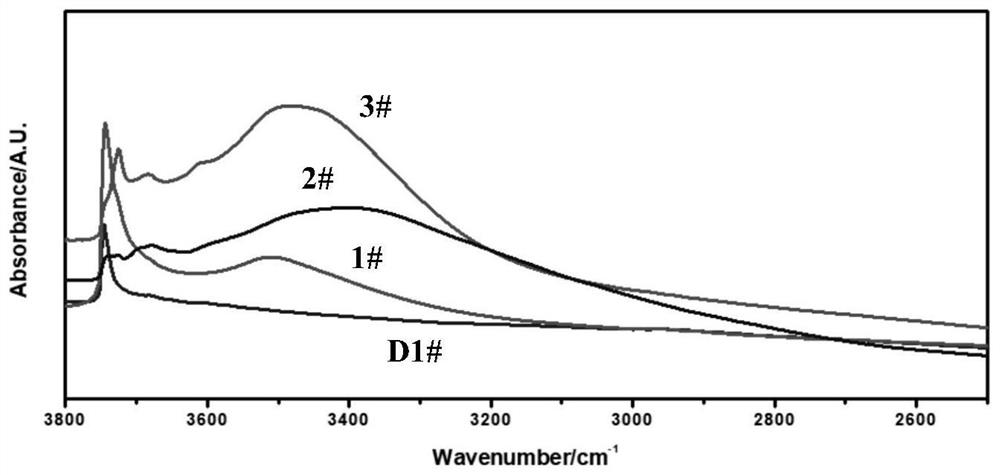

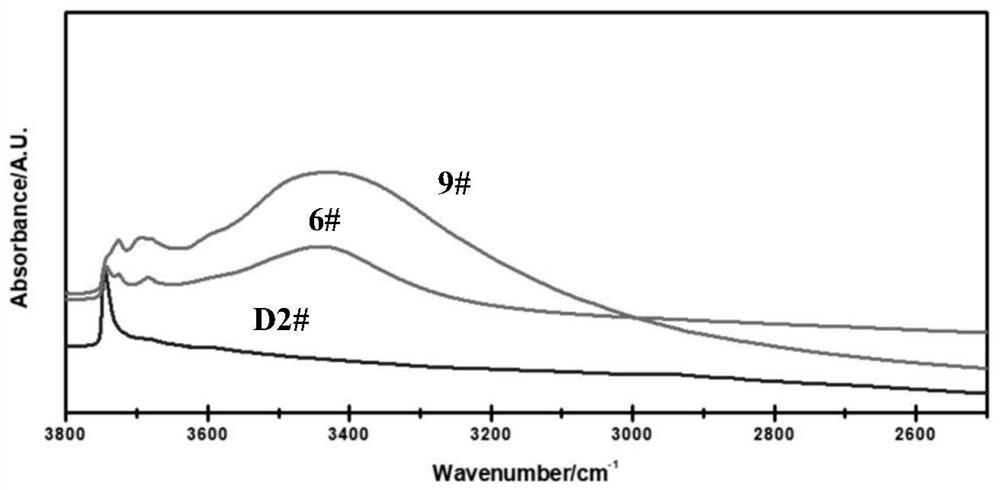

Embodiment 1

[0038] Weigh 0.75gNaOH, 49.8g of sodium silicate (SiO 2 Mass fraction 60%, Na 2 (2 mass fraction 10%) joins 22.5g deionized water, adds 0.36g methyltriethoxysilane and stirs evenly with magnetic stirrer; Then 4.28g aluminum sulfate is completely dissolved in 5g water, slowly adds the concentrated sulfuric acid of 2.25g (98%); The fully dissolved aluminum sulfate solution is slowly dripped into the solution containing sodium silicate, adds 25.9g tetrapropylammonium hydroxide TPAOH, stirs at room temperature for 6 hours, obtains the sol, and the molar composition in the sol is: 18Na 2 O:99.6SiO 2 -Inorg-Si:0.4SiO2 2 -Org-Si:2.5Al 2 o 3 :12SO 4 2- :4000H 2 O: 25.4TPAOH; put the obtained sol into an autoclave lined with polytetrafluoroethylene, control the hydrothermal crystallization temperature of 170°C and the hydrothermal crystallization time of 25 hours; obtain the solid through filtration and dry at 110°C for 8 hours , and roasted at 540°C for 10 hours to obtain a de...

Embodiment 2

[0040] Weigh 0.75gNaOH, 49.25g of sodium silicate (SiO 2 Mass fraction 60%, Na 2 (2 mass fraction 10%) joins 22.5g deionized water, adds 1.34g methyltriethoxysilane and stirs evenly with magnetic stirrer; Then 4.28g aluminum sulfate is completely dissolved in 5g water, slowly adds the concentrated sulfuric acid of 2.25g (98%); The aluminum sulfate solution that dissolves completely is slowly dripped in the solution that contains sodium silicate, adds 30.7g tetrapropyl ammonium hydroxide TPAOH, stirs at room temperature 6 hours, obtains sol, and molar composition is in the sol: 18Na 2 O:98.5SiO 2 -Inorg-Si:1.5SiO2 2 -Org-Si:2.5Al 2 o 3 :12SO 4 2- :4000H 2 O: 30.2TPAOH; put the obtained sol into an autoclave lined with polytetrafluoroethylene, control the hydrothermal crystallization temperature of 170°C and the hydrothermal crystallization time of 25 hours; obtain the solid through filtration and dry at 110°C for 8 hours , and roasted at 540°C for 10 hours to obtain a d...

Embodiment 3

[0042] Weigh 0.75gNaOH, 48.6g of sodium silicate (SiO 2 Mass fraction 60%, Na 2 (2 mass fraction 10%) joins 22.5g deionized water, adds 2.50g methyltriethoxysilane and stirs evenly with magnetic stirrer; Then 4.28g aluminum sulfate is completely dissolved in 5g water, slowly adds the concentrated sulfuric acid of 2.25g (98%); The aluminum sulfate solution that dissolves completely is slowly dripped in the solution that contains sodium silicate, adds 30.7g tetrapropyl ammonium hydroxide TPAOH, stirs at room temperature 6 hours, obtains sol, and molar composition is in the sol: 18Na 2 O:97.2SiO 2 -Inorg-Si:2.8SiO2 2 -Org-Si:2.5Al 2 o 3 :12SO 4 2- :4000H 2 O: 30.2TPAOH; put the obtained sol into an autoclave lined with polytetrafluoroethylene, control the hydrothermal crystallization temperature of 170°C and the hydrothermal crystallization time of 25 hours; obtain the solid through filtration and dry at 110°C for 8 hours , and roasted at 540°C for 10 hours to obtain a de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com