Full-automatic gluing and splicing device for instrument processing

A technology of instrumentation and splicing devices, which is applied in the direction of material gluing, spraying devices, connecting components, etc., can solve the problems of reduced processing efficiency, difficult gluing operation of splicing devices, and difficulty in ensuring installation quality, so as to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

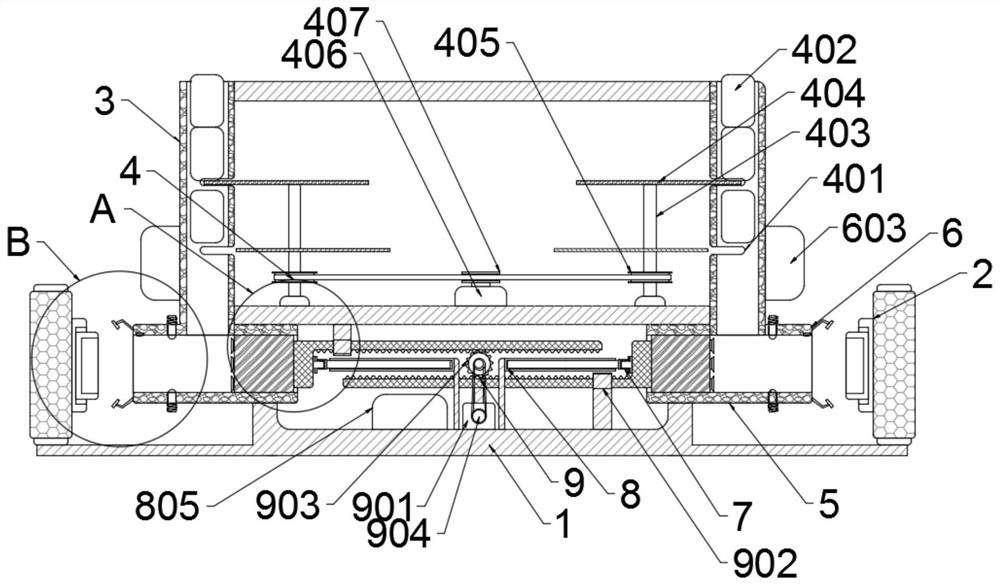

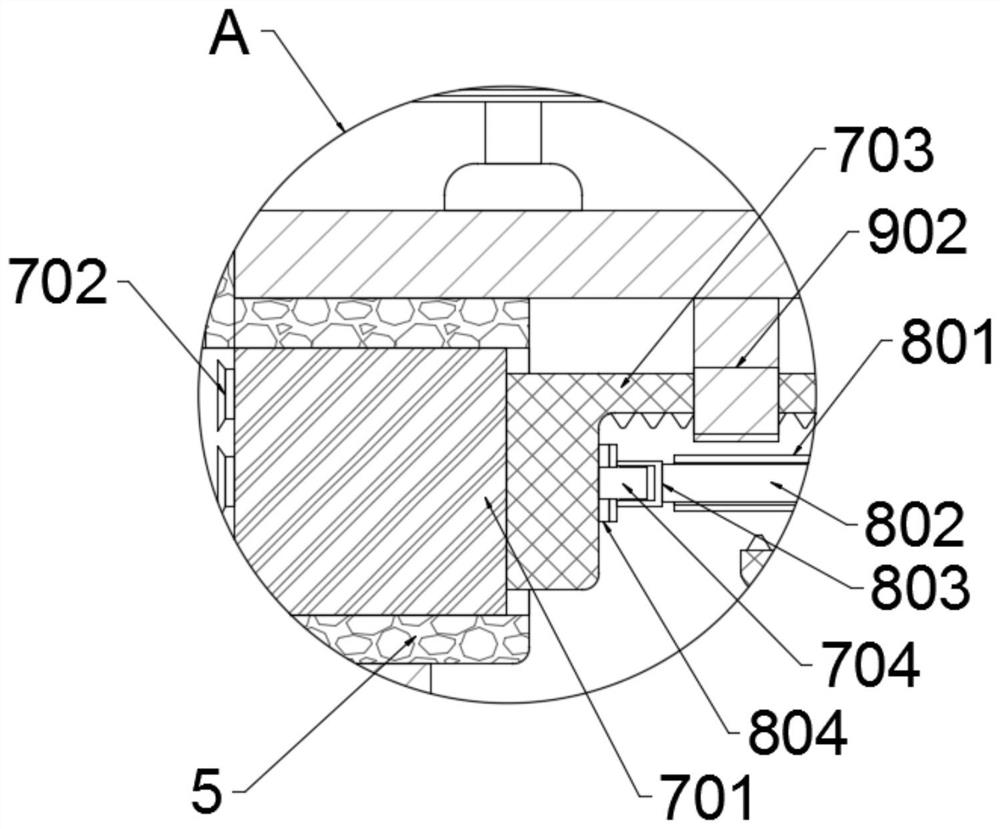

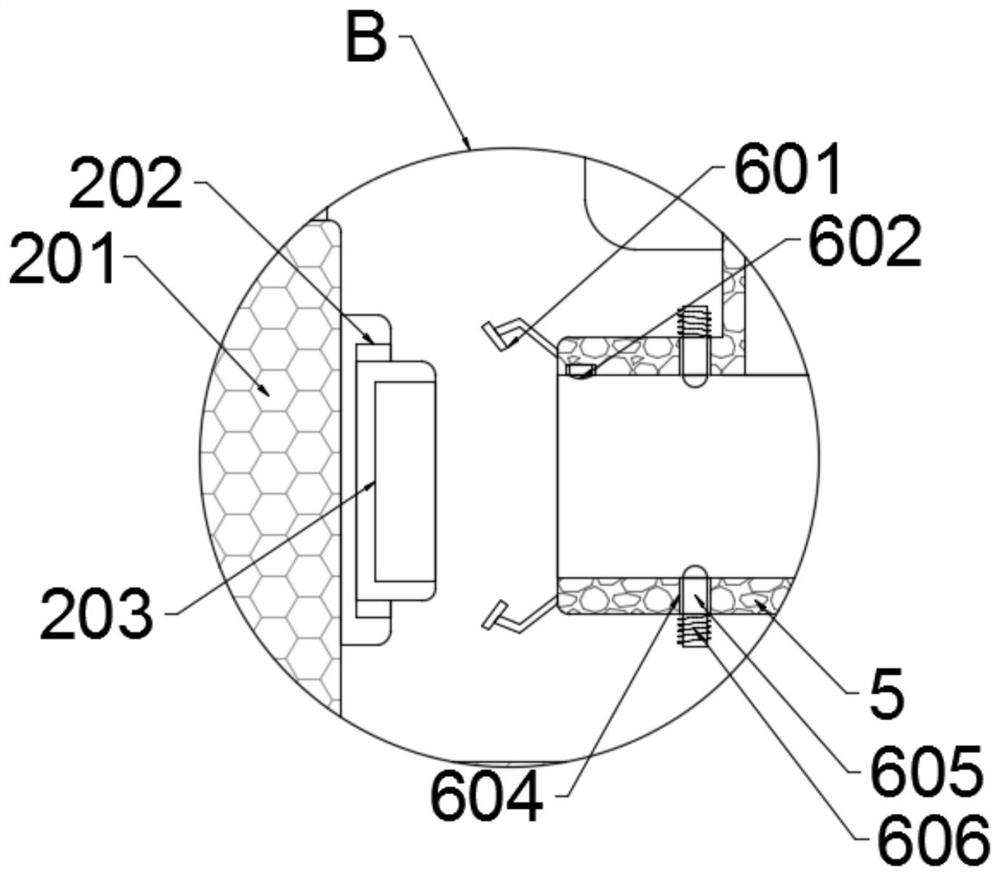

[0028] Example 1: Please refer to Figure 1-2 , a fully automatic gluing and splicing device for instrumentation processing, including a mounting frame 1, a transmission mechanism 2 is symmetrically installed on both sides of the mounting frame 1, and a feeding channel 3 is installed on the mounting frame 1 inside the transmission mechanism 2, and the feeding channel 3 A feeding mechanism 4 is installed on the top, and a discharge channel 5 is connected to the bottom of the feeding channel 3. A glue spraying mechanism 6 is installed on the outside of the discharge channel 5, and a pushing mechanism 7 is installed on the inside of the discharging channel 5. The pushing mechanism 7 includes a negative The pressure block 701, the negative pressure block 701 and the discharge channel 5 fit each other, the front side of the negative pressure block 701 is evenly connected with the suction cup 702, and the back side of the negative pressure block 701 is connected with the drive bar 70...

Embodiment 2

[0035] Example 2: Please refer to Figure 1-3 , a fully automatic gluing and splicing device for instrumentation processing, including a mounting frame 1, a transmission mechanism 2 is symmetrically installed on both sides of the mounting frame 1, and a feeding channel 3 is installed on the mounting frame 1 inside the transmission mechanism 2, and the feeding channel 3 A feeding mechanism 4 is installed on the top, and a discharge channel 5 is connected to the bottom of the feeding channel 3. A glue spraying mechanism 6 is installed on the outside of the discharge channel 5, and a pushing mechanism 7 is installed on the inside of the discharging channel 5. The pushing mechanism 7 includes a negative The pressure block 701, the negative pressure block 701 and the discharge channel 5 fit each other, the front side of the negative pressure block 701 is evenly connected with the suction cup 702, and the back side of the negative pressure block 701 is connected with the drive bar 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com