Rapid mold stripping device for capacitor plastic shell processing

A technology for plastic shells and capacitors, which is applied in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of difficult separation of plastic parts, easily damaged plastic parts, and large manpower demand, so as to improve the effect of mold release, reduce production costs, and guarantee The effect of the output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

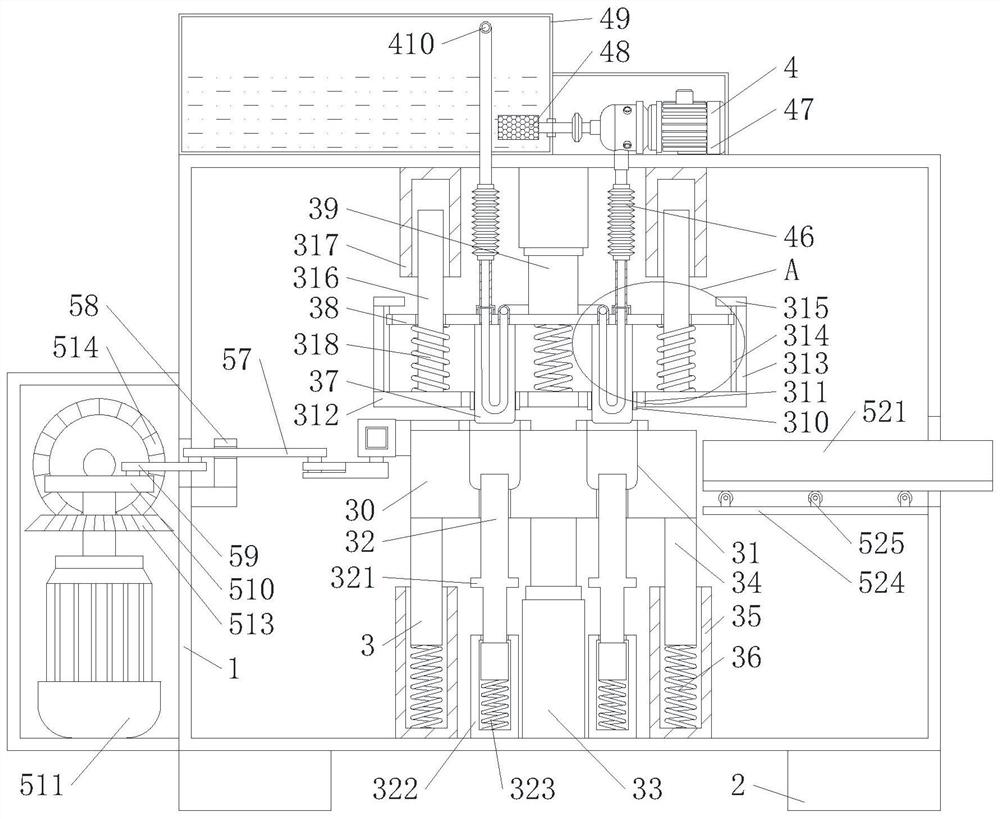

[0035] A rapid ejection device for capacitor plastic shell processing, comprising a hollow case 1 and a plurality of support feet 2 installed at the lower end of the case 1, a mold ejection mechanism 3 is provided in the inner cavity of the case 1, and is used for the plastic case of capacitors. Forming and mold removal, the inner cavity of the chassis 1 is provided with a cooling mechanism 4 that runs through the top wall of the chassis 1, which is used for rapid prototyping of the capacitor plastic shell, and the inner cavity of the chassis 1 is also provided with a discharge mechanism 5, which is used for the formed capacitor Quick discharge of plastic shell;

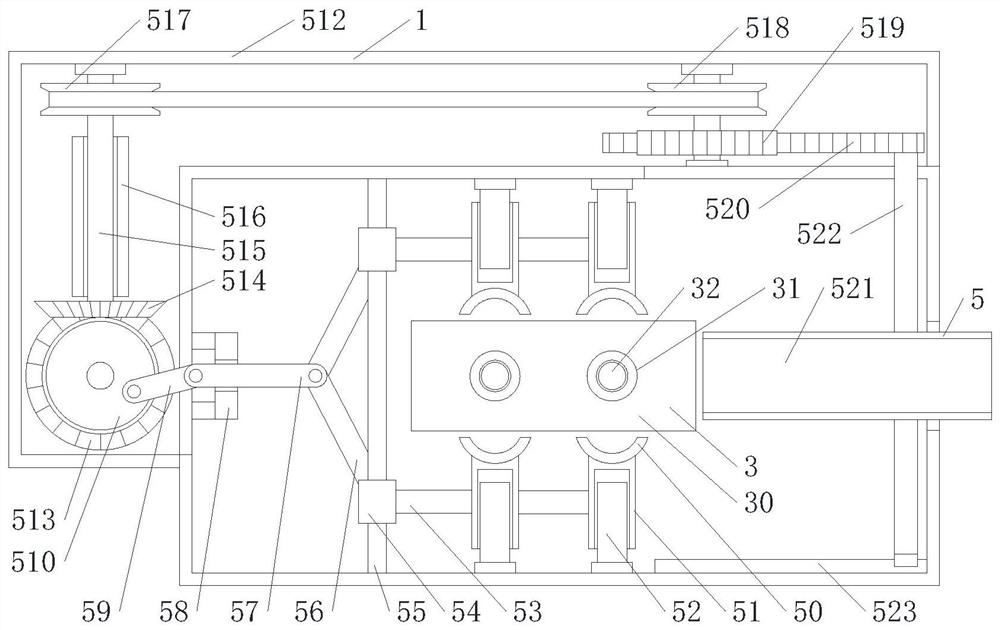

[0036] In this example, if Figure 2-4 As shown, the ejection mechanism 3 includes a lower mold 30 vertically slidably connected in the inner cavity of the cabinet 1, and a plurality of cavities 31 for capacitor casing molding are provided on the top wall of the lower mold 30. What about the cavities 31? A plurality...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is that, as Figure 2-5 As shown, the inner cavity of the cabinet 1 corresponding to the position below the punch 37 is horizontally installed with a discharge chute 521, and the discharge trough 521 extends through the side wall of the cabinet 1 to the outer cavity of the cabinet 1, and the two sides of the discharge chute 521 Fixed columns 522 are installed on the side walls, wherein the fixed columns on one side extend horizontally and are slidably connected with guide rails 523 through sliding seats. Extending through the side wall of the cabinet 1 and horizontally connected with a rack 520, the rack 520 is meshed with a drive gear 519, the central axis of the drive gear 519 extends to both sides and is rotatably mounted on the rear side wall of the cabinet 1 through a shaft seat, and The central shaft of the driving gear 519 is provided with a driven pulley 518, and the driven pulley 518 is connected with a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com